Duplex properties offer a unique blend of multi-family living and investment potential, combining two separate units within one building. These homes provide opportunities for rental income, increased property value, and flexible living arrangements. Discover how owning a duplex can enhance your real estate portfolio and lifestyle by exploring the detailed insights ahead.

Table of Comparison

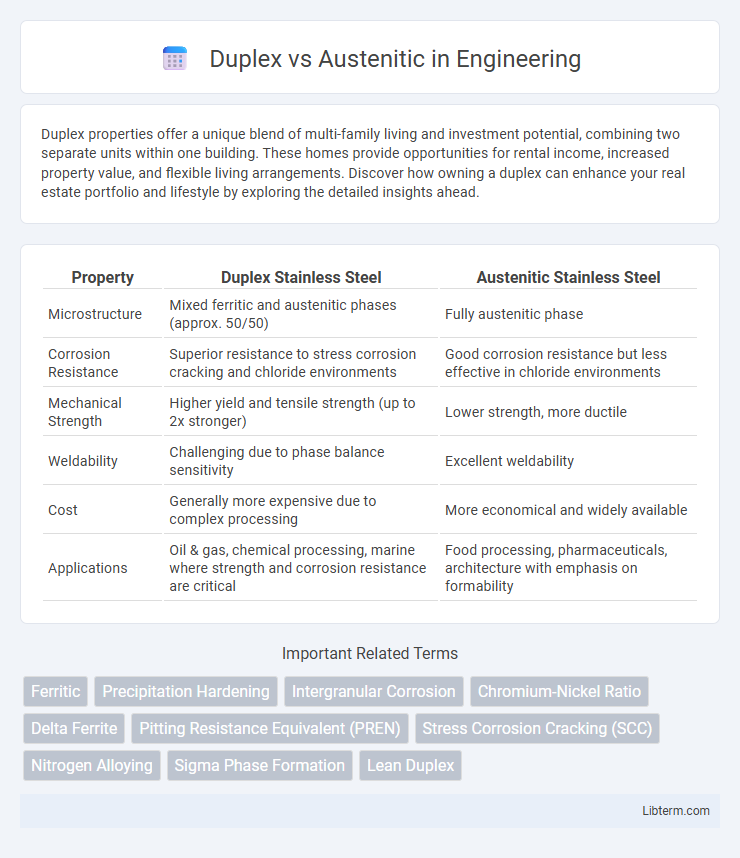

| Property | Duplex Stainless Steel | Austenitic Stainless Steel |

|---|---|---|

| Microstructure | Mixed ferritic and austenitic phases (approx. 50/50) | Fully austenitic phase |

| Corrosion Resistance | Superior resistance to stress corrosion cracking and chloride environments | Good corrosion resistance but less effective in chloride environments |

| Mechanical Strength | Higher yield and tensile strength (up to 2x stronger) | Lower strength, more ductile |

| Weldability | Challenging due to phase balance sensitivity | Excellent weldability |

| Cost | Generally more expensive due to complex processing | More economical and widely available |

| Applications | Oil & gas, chemical processing, marine where strength and corrosion resistance are critical | Food processing, pharmaceuticals, architecture with emphasis on formability |

Overview of Duplex and Austenitic Stainless Steels

Duplex stainless steels combine austenitic and ferritic microstructures to provide high strength and excellent resistance to stress corrosion cracking and chloride pitting, making them ideal for harsh environments like chemical processing and marine applications. Austenitic stainless steels, primarily composed of iron, chromium, and nickel, offer superior corrosion resistance and excellent ductility, commonly used in food processing, architecture, and medical instruments. The balanced phases in duplex steels provide enhanced mechanical properties compared to purely austenitic grades, which excel in formability and weldability.

Chemical Composition Differences

Duplex stainless steel contains approximately 18-28% chromium, 4-6.5% nickel, and 3-5% molybdenum, along with significant amounts of nitrogen (0.08-0.3%) to enhance strength and corrosion resistance. Austenitic stainless steel typically has higher nickel content, ranging from 8-35%, with chromium levels around 16-26% but usually lacks molybdenum or contains it in lower quantities, and nitrogen content is minimal. The balanced composition in duplex alloys results in a dual-phase microstructure, combining ferritic and austenitic phases, which differs chemically and structurally from the fully austenitic microstructure of austenitic stainless steel.

Microstructure Comparison

Duplex stainless steel features a balanced microstructure of approximately 50% ferrite and 50% austenite, enhancing its strength and corrosion resistance. In contrast, austenitic stainless steel primarily consists of a single-phase face-centered cubic (FCC) austenitic structure, offering superior ductility and toughness but lower yield strength. The dual-phase microstructure in duplex steels provides improved resistance to stress corrosion cracking compared to the fully austenitic microstructure.

Mechanical Properties Analysis

Duplex stainless steels exhibit higher tensile strength, typically ranging from 650 to 850 MPa, compared to austenitic grades like 304 and 316, which generally have tensile strengths around 500 to 750 MPa. Duplex steels also offer superior yield strength, often double that of austenitic steels, enhancing resistance to deformation under stress. While austenitic stainless steels provide better ductility and toughness, duplex grades excel in fatigue resistance and have improved stress corrosion cracking resistance due to their mixed microstructure of ferrite and austenite phases.

Corrosion Resistance Capabilities

Duplex stainless steel exhibits superior corrosion resistance due to its balanced microstructure of austenite and ferrite, offering enhanced resistance to stress corrosion cracking and chloride-induced pitting compared to austenitic stainless steel. Austenitic stainless steel, such as grades 304 and 316, provides good overall corrosion resistance but is more susceptible to localized corrosion in aggressive environments. The higher chromium, molybdenum, and nitrogen content in duplex stainless steel significantly improves its resistance to crevice corrosion and chloride stress corrosion cracking relative to austenitic grades.

Common Applications and Industries

Duplex stainless steel, known for its high strength and excellent corrosion resistance, is commonly used in chemical processing, oil and gas, and marine industries where resistance to chloride stress corrosion is critical. Austenitic stainless steel, favored for its superior formability and toughness, finds widespread applications in food processing, pharmaceuticals, and architecture, particularly in environments requiring high corrosion resistance and good weldability. Both materials serve key roles in industrial equipment, piping systems, and structural components, selected based on their mechanical properties and environmental durability.

Weldability and Fabrication Considerations

Duplex stainless steels offer higher strength and improved corrosion resistance compared to austenitic grades but require precise control of heat input during welding to prevent phase imbalance and sigma phase formation, which can impair toughness. Austenitic stainless steels, known for excellent weldability and ductility, typically tolerate a wider range of welding conditions without significant cracking or distortion, making fabrication easier in complex shapes. Careful preheat and interpass temperature control are more critical for duplex alloys to maintain optimal microstructure and mechanical properties during fabrication.

Cost and Availability Factors

Duplex stainless steel typically costs more than austenitic grades due to its higher alloy content, including increased amounts of chromium, molybdenum, and nitrogen, which enhance strength and corrosion resistance. Austenitic stainless steel is more widely available and produced in larger volumes globally, making it more cost-effective and easier to source for various applications. The price difference also reflects the balance between superior mechanical properties and market demand, where duplex offers superior resistance to stress corrosion cracking while austenitic remains the standard choice for general purpose use.

Performance in Extreme Environments

Duplex stainless steel exhibits superior performance in extreme environments due to its balanced microstructure of ferrite and austenite, providing enhanced strength, corrosion resistance, and stress corrosion cracking resistance compared to austenitic stainless steel. Austenitic stainless steels, while highly corrosion-resistant in many environments, often show reduced resistance to chloride-induced stress corrosion cracking and lower strength at elevated temperatures than duplex grades. Duplex alloys perform exceptionally well in harsh conditions such as seawater exposure, chemical processing, and high-pressure applications, making them the preferred choice for extreme environments requiring durability and reliability.

Selecting the Right Stainless Steel for Your Needs

Duplex stainless steel offers a unique combination of high strength and excellent corrosion resistance, making it ideal for aggressive environments such as chemical processing and marine applications. Austenitic stainless steel, known for its superior formability and resistance to oxidation, is preferred in food processing and architectural projects. Selecting the right stainless steel depends on balancing factors like mechanical strength, corrosion resistance, and fabrication requirements.

Duplex Infographic

libterm.com

libterm.com