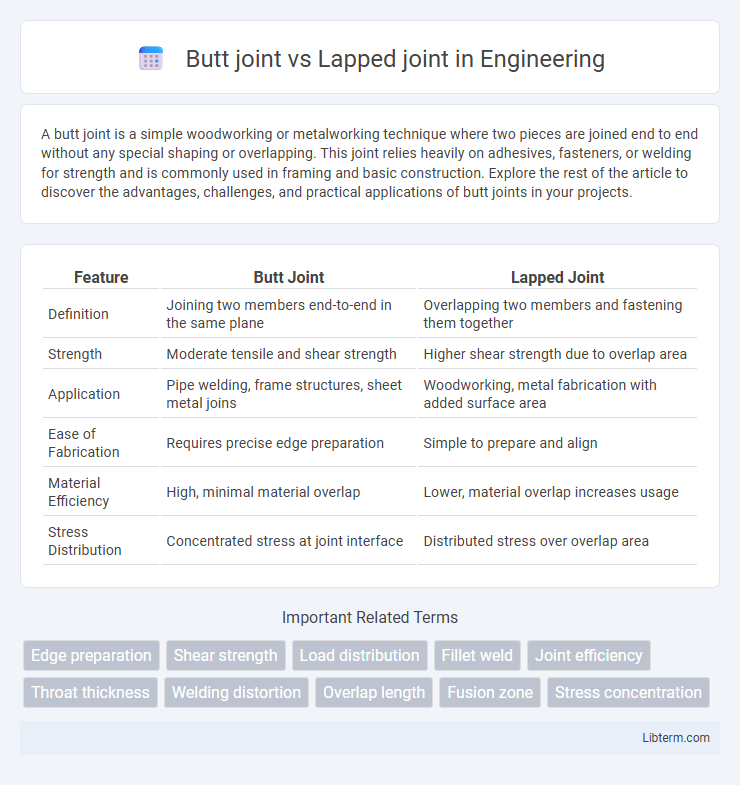

A butt joint is a simple woodworking or metalworking technique where two pieces are joined end to end without any special shaping or overlapping. This joint relies heavily on adhesives, fasteners, or welding for strength and is commonly used in framing and basic construction. Explore the rest of the article to discover the advantages, challenges, and practical applications of butt joints in your projects.

Table of Comparison

| Feature | Butt Joint | Lapped Joint |

|---|---|---|

| Definition | Joining two members end-to-end in the same plane | Overlapping two members and fastening them together |

| Strength | Moderate tensile and shear strength | Higher shear strength due to overlap area |

| Application | Pipe welding, frame structures, sheet metal joins | Woodworking, metal fabrication with added surface area |

| Ease of Fabrication | Requires precise edge preparation | Simple to prepare and align |

| Material Efficiency | High, minimal material overlap | Lower, material overlap increases usage |

| Stress Distribution | Concentrated stress at joint interface | Distributed stress over overlap area |

Butt Joint vs Lapped Joint: An Overview

Butt joints connect two pieces of material end-to-end without overlapping, commonly used in welding and carpentry for straightforward assembly. Lapped joints involve overlapping two pieces partially, offering increased strength and resistance to bending, often found in metalwork and woodworking for structural stability. Choosing between butt joint and lapped joint depends on factors such as load distribution, material thickness, and application requirements.

Key Differences Between Butt and Lapped Joints

Butt joints involve two pieces of material joined end-to-end in a single plane, providing a straightforward, cost-effective connection primarily used in welding and woodworking. Lapped joints overlap two pieces of material, creating a stronger bond with increased surface area and better resistance to shear forces, commonly found in metal fabrication and carpentry. The key differences lie in their structural strength, complexity, and load distribution, with lapped joints offering enhanced durability compared to the simpler, less robust butt joints.

Structural Strength: Butt Joint Compared to Lapped Joint

Butt joints often exhibit lower structural strength compared to lapped joints due to limited bonding surface area, resulting in higher stress concentration at the joint interface. Lapped joints provide increased load distribution and enhanced mechanical interlocking, which significantly improves their resistance to tensile and shear forces. For applications requiring superior durability and load-bearing capacity, lapped joints are preferred over butt joints.

Ease of Fabrication: Butt Joint vs Lapped Joint

Butt joints offer ease of fabrication by requiring minimal preparation, as the two pieces are simply aligned and joined end-to-end, making them ideal for quick assembly. Lapped joints involve overlapping the materials, which can add complexity due to the need for precise fitting and additional surface preparation. While butt joints typically save time and labor, lapped joints may provide enhanced strength but demand more meticulous fabrication efforts.

Common Applications for Butt and Lapped Joints

Butt joints are commonly used in woodworking, metal fabrication, and construction for framing, paneling, and simple edge-to-edge joining where ease of assembly is essential. Lapped joints find frequent application in furniture making, cabinetry, and automotive bodywork due to their enhanced strength and increased surface area for adhesive bonding. Both joint types are integral in manufacturing processes requiring different balance points between structural integrity and fabrication simplicity.

Material Compatibility: Choosing Butt or Lapped Joint

Butt joints provide superior material compatibility for metals and plastics that require a flush surface, facilitating stronger welds and precise alignment. Lapped joints are better suited for dissimilar materials or thin sheets, offering enhanced mechanical interlocking and load distribution despite potential corrosion risks at overlapping areas. Selecting between butt and lapped joints depends on factors like material thickness, corrosion resistance, and joint load requirements to optimize structural integrity.

Cost Considerations: Butt Joint vs Lapped Joint

Butt joints generally offer lower fabrication costs due to simpler preparation and alignment, requiring minimal material overlap and less welding time. Lapped joints, while stronger, involve additional material usage and increased labor for proper fitting, leading to higher overall expenses. Choosing between these joints depends on balancing budget constraints with the required joint strength and durability for the specific application.

Aesthetic Impact: Visual Differences Between Butt and Lapped Joints

Butt joints create a clean, minimalistic appearance with edges aligned flush, making them ideal for modern, sleek designs. Lapped joints produce a layered, overlapping look that adds visual depth and texture, often favored in traditional or rustic woodworking. The aesthetic impact depends on the desired style, with butt joints emphasizing simplicity and lapped joints enhancing complexity and craftsmanship detail.

Joining Methods: Welding, Gluing, and Fastening

Butt joints and lapped joints serve different purposes in joining methods such as welding, gluing, and fastening. Butt joints require careful alignment and welding techniques like MIG or TIG for strong, flush welds, while lapped joints offer increased surface area for stronger adhesive bonds and mechanical fasteners like rivets or screws. In gluing, lapped joints outperform butt joints by providing enhanced adhesive contact, resulting in higher load resistance and durability.

Pros and Cons of Butt Joints vs Lapped Joints

Butt joints offer simplicity and ease of assembly, making them cost-effective and suitable for quick fabrication, but they often lack strength and require reinforcement for durability. Lapped joints provide enhanced mechanical strength and better resistance to shear forces due to the overlapping surfaces, although they can be bulkier and demand more precise alignment during assembly. Choosing between butt joints and lapped joints depends on the application's load requirements, space constraints, and manufacturing complexity.

Butt joint Infographic

libterm.com

libterm.com