Thermomechanical fatigue testing machines simulate real-world operating conditions by applying cyclic mechanical loads combined with thermal variations to evaluate material durability. These machines are essential for assessing the lifespan and performance of components exposed to fluctuating stresses and temperatures. Discover how this advanced testing technology can enhance Your material analysis by reading the full article.

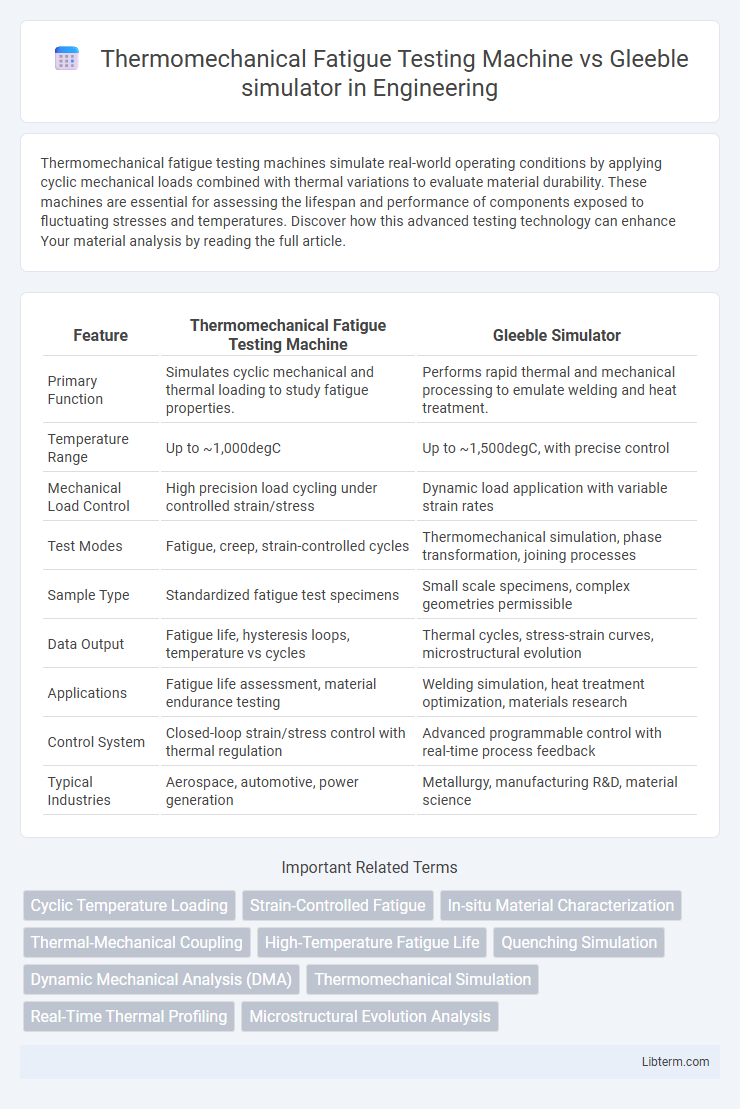

Table of Comparison

| Feature | Thermomechanical Fatigue Testing Machine | Gleeble Simulator |

|---|---|---|

| Primary Function | Simulates cyclic mechanical and thermal loading to study fatigue properties. | Performs rapid thermal and mechanical processing to emulate welding and heat treatment. |

| Temperature Range | Up to ~1,000degC | Up to ~1,500degC, with precise control |

| Mechanical Load Control | High precision load cycling under controlled strain/stress | Dynamic load application with variable strain rates |

| Test Modes | Fatigue, creep, strain-controlled cycles | Thermomechanical simulation, phase transformation, joining processes |

| Sample Type | Standardized fatigue test specimens | Small scale specimens, complex geometries permissible |

| Data Output | Fatigue life, hysteresis loops, temperature vs cycles | Thermal cycles, stress-strain curves, microstructural evolution |

| Applications | Fatigue life assessment, material endurance testing | Welding simulation, heat treatment optimization, materials research |

| Control System | Closed-loop strain/stress control with thermal regulation | Advanced programmable control with real-time process feedback |

| Typical Industries | Aerospace, automotive, power generation | Metallurgy, manufacturing R&D, material science |

Overview of Thermomechanical Fatigue Testing

Thermomechanical fatigue testing machines accurately simulate cyclic mechanical and thermal stresses to evaluate material durability under service-like conditions. These systems provide precise control over strain, temperature, and load, enabling detailed analysis of fatigue life and failure mechanisms in metals and alloys. Compared to Gleeble simulators, thermomechanical fatigue testing machines specialize in long-term fatigue behavior rather than rapid thermal-mechanical processing.

Introduction to Thermomechanical Fatigue Testing Machines

Thermomechanical fatigue testing machines are designed to evaluate material durability by subjecting specimens to simultaneous thermal cycles and mechanical strain, simulating real-world service conditions. These machines combine precise temperature control with mechanical loading to assess material behavior under complex thermo-mechanical stresses, essential for predicting component lifespan in aerospace, automotive, and power generation industries. Compared to Gleeble simulators, which emphasize rapid thermal and mechanical simulation for microstructural analysis, thermomechanical fatigue testing machines prioritize long-term fatigue resistance and damage accumulation under cyclic thermal and mechanical loading.

What is a Gleeble Simulator?

A Gleeble simulator is a specialized thermomechanical testing machine designed to replicate complex thermal and mechanical conditions encountered during metal processing, such as welding or forging. It enables precise control of temperature, strain, and strain rate, allowing detailed analysis of material behavior under cyclic thermal-mechanical loads. Gleeble simulators are widely used in research to optimize material properties and predict fatigue life in industrial applications.

Key Features of Thermomechanical Fatigue Testing Machines

Thermomechanical fatigue testing machines feature precise control of cyclic loading and temperature variation to simulate real-world thermal and mechanical stresses on materials, enabling comprehensive evaluation of fatigue life and crack initiation. These machines incorporate high-frequency actuation systems, integrated strain measurement, and programmable temperature profiles, allowing for customized test cycles that mimic service conditions with exceptional accuracy. Unlike Gleeble simulators, which focus on rapid thermal treatments and microstructural simulations, thermomechanical fatigue testers are optimized for long-duration fatigue crack growth analysis under combined mechanical and thermal stresses.

Core Components of Gleeble Simulators

Gleeble simulators feature advanced core components such as a water-cooled copper jaw system, an induction or resistance heating unit, and a precise microcomputer control system for accurate thermomechanical fatigue testing. The copper jaws ensure uniform heat distribution and rapid cooling cycles, enabling realistic simulation of thermal and mechanical stress conditions. Unlike conventional thermomechanical fatigue testing machines, Gleeble's integrated control and data acquisition systems provide superior real-time monitoring and material response analysis.

Comparative Testing Capabilities

Thermomechanical fatigue testing machines offer precise control over cyclic mechanical strain and temperature to simulate real-service conditions, enabling detailed analysis of material behavior under combined thermal and mechanical loads. Gleeble simulators provide rapid heating and controlled deformation with high flexibility in thermal-mechanical cycles, facilitating microstructural evolution studies alongside fatigue testing. Comparative testing shows Gleeble excels in simulating complex thermal gradients and transient conditions, while thermomechanical fatigue testing machines are superior for long-term cyclic fatigue durability assessments under stable temperature profiles.

Temperature and Load Control Accuracy

Thermomechanical fatigue testing machines provide precise temperature control, typically within +-1degC, enabling accurate simulation of cyclic thermal stresses under defined load conditions with load resolution often better than 1 N. Gleeble simulators offer superior thermal gradients and rapid heating/cooling rates, achieving temperature control accuracy around +-0.5degC and load control with dynamic response times in milliseconds, facilitating more realistic replication of complex thermomechanical processes. The Gleeble's advanced real-time feedback systems ensure highly accurate load control during thermal cycles, surpassing traditional testing machines in capturing transient phenomena critical for material behavior analysis.

Applications in Material Science

Thermomechanical fatigue testing machines are essential for simulating cyclic thermal and mechanical stresses to evaluate the durability and failure mechanisms of metals and alloys in aerospace and automotive industries. Gleeble simulators provide precise control of thermal and mechanical parameters for rapid heating and cooling cycles, enabling the study of phase transformations, weldability, and high-temperature deformation behaviors in advanced materials. Both instruments are critical in material science research for developing heat-resistant alloys and optimizing manufacturing processes like forging and welding.

Advantages and Limitations of Each System

Thermomechanical fatigue testing machines offer precise control over cyclic loading and temperature conditions, enabling detailed analysis of material fatigue behavior under realistic service environments. Gleeble simulators provide rapid thermal and mechanical simulation with excellent flexibility in replicating complex thermal-mechanical cycles and microstructural changes, making them suitable for studying welding and phase transformations. However, thermomechanical fatigue machines are limited by longer testing times and less adaptability to rapid thermal transients, while Gleeble systems may have size constraints and higher operational complexity, impacting scalability and routine testing efficiency.

Choosing the Right Equipment for Research and Industry

Thermomechanical fatigue testing machines offer precise cyclic loading and thermal control essential for studying material behavior under real-service conditions, making them ideal for fatigue life prediction and component design. Gleeble simulators provide versatile, rapid thermal-mechanical processing capabilities, enabling simulation of welding, heat treatment, and deformation processes, crucial for microstructural analysis and process optimization. Selecting the right equipment depends on research objectives: choose thermomechanical fatigue testers for endurance and durability testing, while Gleeble systems suit complex thermal-mechanical simulations and microstructural evolution studies.

Thermomechanical Fatigue Testing Machine Infographic

libterm.com

libterm.com