The electrostrictive effect refers to the property of certain materials to change shape or deform in response to an applied electric field, resulting from the material's intrinsic crystal lattice distortion. This phenomenon is widely utilized in precision actuators, sensors, and transducers due to its reversible and quadratic displacement behavior. Explore the rest of the article to understand how the electrostrictive effect can impact your applications and enhance device performance.

Table of Comparison

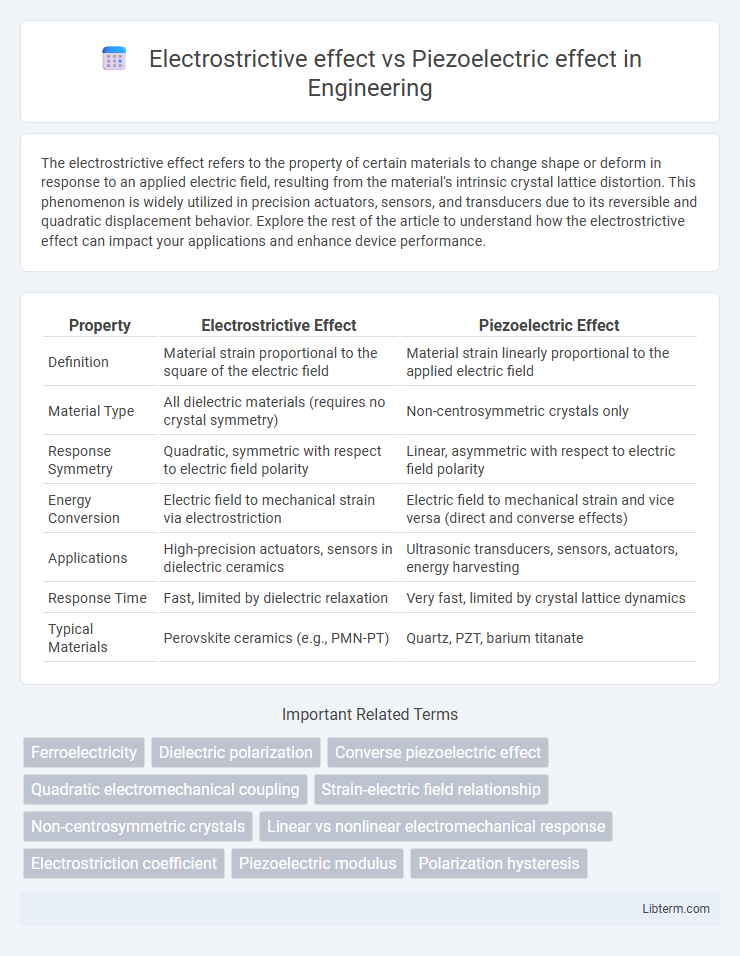

| Property | Electrostrictive Effect | Piezoelectric Effect |

|---|---|---|

| Definition | Material strain proportional to the square of the electric field | Material strain linearly proportional to the applied electric field |

| Material Type | All dielectric materials (requires no crystal symmetry) | Non-centrosymmetric crystals only |

| Response Symmetry | Quadratic, symmetric with respect to electric field polarity | Linear, asymmetric with respect to electric field polarity |

| Energy Conversion | Electric field to mechanical strain via electrostriction | Electric field to mechanical strain and vice versa (direct and converse effects) |

| Applications | High-precision actuators, sensors in dielectric ceramics | Ultrasonic transducers, sensors, actuators, energy harvesting |

| Response Time | Fast, limited by dielectric relaxation | Very fast, limited by crystal lattice dynamics |

| Typical Materials | Perovskite ceramics (e.g., PMN-PT) | Quartz, PZT, barium titanate |

Introduction to Electrostrictive and Piezoelectric Effects

Electrostrictive and piezoelectric effects both describe material responses to electric fields, but electrostriction causes strain proportional to the square of the electric field, occurring in all dielectrics, whereas piezoelectricity produces linear strain only in non-centrosymmetric crystals. Electrostrictive materials exhibit reversible deformation due to polarization-induced lattice distortion without polarity dependence, contrasting with piezoelectric materials that generate electric charges from mechanical stress or vice versa. These fundamental differences dictate their distinct applications in sensors, actuators, and transducers within advanced electromechanical systems.

Fundamental Principles: How Each Effect Works

The electrostrictive effect occurs when a dielectric material deforms in response to an applied electric field, causing a quadratic strain proportional to the square of the field strength, independent of field polarity. The piezoelectric effect arises from the linear coupling between mechanical stress and electric polarization in non-centrosymmetric crystals, producing strain directly proportional to the applied electric field with polarity dependence. Electrostriction is inherent to all dielectric materials, driven by electric dipole alignment, whereas piezoelectricity requires specific crystal symmetry for charge displacement and mechanical deformation.

Material Requirements and Types

Electrostrictive materials require non-centrosymmetric crystal structures, typically found in perovskite ceramics like lead magnesium niobate (PMN), and demonstrate strain proportional to the square of the applied electric field, regardless of polarity. Piezoelectric materials, including quartz and lead zirconate titanate (PZT), possess non-centrosymmetric crystal lattices enabling a linear strain response directly proportional to the electric field and are commonly used in sensors and actuators. While electrostrictive effects are observable in all dielectrics under high fields with specific polarization, the piezoelectric effect strictly requires non-centrosymmetric materials exhibiting spontaneous polarization.

Mechanisms of Electrical Response

The electrostrictive effect arises from the quadratic relationship between the applied electric field and induced strain, caused by the alignment of electric dipoles in dielectric materials without requiring crystal asymmetry. In contrast, the piezoelectric effect is a linear response where strain is generated directly by an electric field in non-centrosymmetric crystals due to the displacement of ions in the crystal lattice. Electrostriction occurs universally in all dielectrics but is generally weaker, while piezoelectricity only occurs in specific materials with asymmetric structures, yielding a more efficient and reversible electromechanical coupling.

Linearity vs. Nonlinearity in Actuation

Electrostrictive effect exhibits a nonlinear relationship between applied electric field and strain, where deformation is proportional to the square of the electric field, resulting in bidirectional strain without polarity dependence. Piezoelectric effect demonstrates a linear correlation, producing strain directly proportional to the applied electric field with reversible deformation that depends on field polarity. This fundamental difference makes piezoelectric materials ideal for precise linear actuation, while electrostrictive materials are better suited for applications requiring large strains but less precise control.

Common Applications: A Comparative Overview

Electrostrictive effects are commonly utilized in precision actuators and adaptive optics due to their ability to produce strain proportional to the square of the electric field, making them ideal for high-frequency and high-stability applications. Piezoelectric effects are widely applied in sensors, ultrasonic transducers, and energy harvesting devices because they generate electrical charge linearly in response to mechanical stress, enabling efficient signal conversion and sensing capabilities. Both phenomena are fundamental in microelectromechanical systems (MEMS), but piezoelectric materials dominate applications requiring direct electromechanical feedback and energy conversion.

Efficiency and Performance Characteristics

The electrostrictive effect exhibits a quadratic response to electric fields, providing high stability and durability but generally lower strain efficiency compared to the linear, higher strain response of piezoelectric materials. Piezoelectric materials offer rapid and highly efficient energy conversion with greater sensitivity, making them superior for dynamic actuation and sensing performance. Electrostrictive polymers excel in applications requiring large displacements with minimal hysteresis, while piezoelectric crystals dominate where precise control and fast response times are critical.

Advantages and Limitations of Each Effect

The electrostrictive effect offers high strain response under an electric field with excellent mechanical stability but typically requires higher electric fields and exhibits slower response times compared to the piezoelectric effect. Piezoelectric materials provide rapid, linear strain responses with lower driving voltages, making them ideal for precise sensing and actuation; however, they suffer from limited strain magnitude and can degrade under repeated mechanical stress. Both effects are critical for actuator and sensor technologies, with electrostriction favored for high-force applications and piezoelectricity preferred for fast, low-energy operations.

Recent Advances in Smart Materials

Recent advances in smart materials have enhanced the understanding of the electrostrictive effect, characterized by quadratic strain response under electric fields, enabling applications in high-precision actuators and sensors. Piezoelectric materials exhibit a linear electromechanical coupling useful for energy harvesting, ultrasonic devices, and adaptive structures, with novel composites improving their sensitivity and operational bandwidth. Cutting-edge research integrates nanostructured electrostrictive polymers and engineered piezoelectric ceramics to optimize performance, durability, and multifunctionality in next-generation smart systems.

Future Prospects and Emerging Trends

The future prospects for the electrostrictive effect lie in advanced smart materials and energy harvesting applications, leveraging its quadratic strain response for improved durability and precision in sensors and actuators. Emerging trends in piezoelectric technology include the development of flexible, lead-free materials and integration into wearable electronics, enhancing efficiency and sustainability in energy conversion and medical devices. Both effects show promise in next-generation microelectromechanical systems (MEMS), combining high sensitivity and miniaturization to drive innovations in robotics and environmental monitoring.

Electrostrictive effect Infographic

libterm.com

libterm.com