Young's modulus measures a material's stiffness by quantifying the ratio of stress to strain in the elastic deformation region. This fundamental property is crucial for engineers and designers to predict how materials will behave under mechanical loads. Discover more about how Young's modulus influences material selection and structural design throughout this article.

Table of Comparison

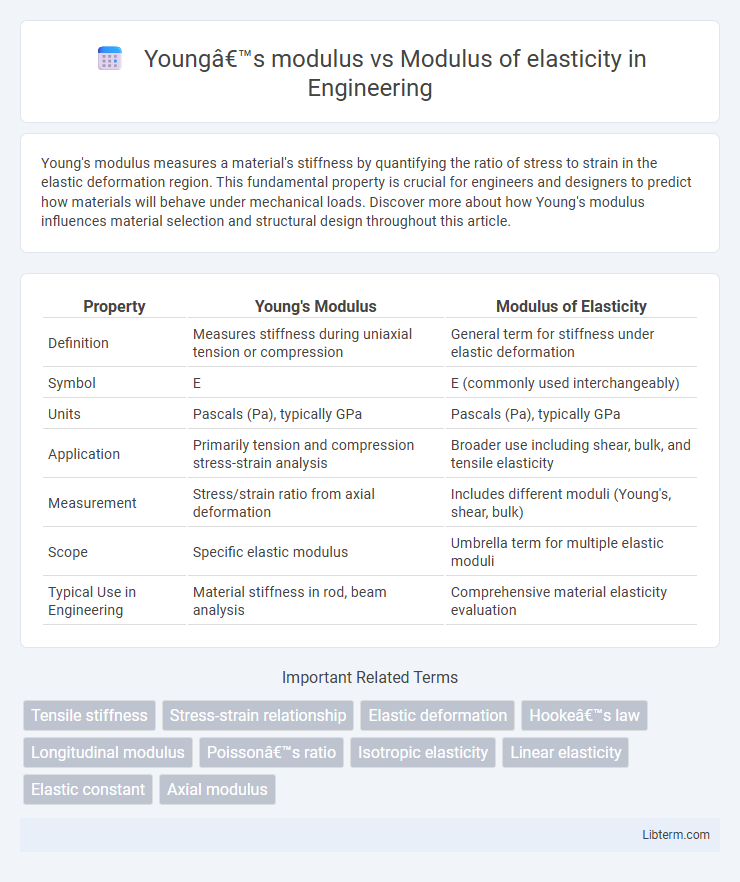

| Property | Young's Modulus | Modulus of Elasticity |

|---|---|---|

| Definition | Measures stiffness during uniaxial tension or compression | General term for stiffness under elastic deformation |

| Symbol | E | E (commonly used interchangeably) |

| Units | Pascals (Pa), typically GPa | Pascals (Pa), typically GPa |

| Application | Primarily tension and compression stress-strain analysis | Broader use including shear, bulk, and tensile elasticity |

| Measurement | Stress/strain ratio from axial deformation | Includes different moduli (Young's, shear, bulk) |

| Scope | Specific elastic modulus | Umbrella term for multiple elastic moduli |

| Typical Use in Engineering | Material stiffness in rod, beam analysis | Comprehensive material elasticity evaluation |

Introduction to Young’s Modulus and Modulus of Elasticity

Young's modulus and modulus of elasticity both quantify a material's ability to resist deformation under stress, with Young's modulus specifically measuring tensile stiffness in linear elastic materials. Modulus of elasticity encompasses various types of stress-strain relationships including tensile, compressive, and shear, serving as a broader term in material science. These moduli are fundamental in engineering to predict material behavior, calculate strain under load, and design components for structural integrity.

Defining Young’s Modulus

Young's modulus, also known as the modulus of elasticity, quantifies a material's intrinsic stiffness by measuring the ratio of tensile stress to tensile strain within its elastic limit. It is a fundamental mechanical property used to predict how much a material will deform under applied force and is expressed in units of pascals (Pa). Young's modulus specifically applies to linear elastic deformation of solids, providing essential data for engineering and materials science applications.

Understanding Modulus of Elasticity

The modulus of elasticity measures a material's resistance to deformation under stress, representing the ratio of stress to strain within the elastic limit. Young's modulus, a specific type of modulus of elasticity, quantifies the tensile stiffness of materials and is crucial for engineering applications involving elongation under tensile loads. Understanding modulus of elasticity enables accurate prediction of material behavior in structural design and mechanical analysis.

Young’s Modulus vs Modulus of Elasticity: Key Differences

Young's modulus specifically measures the linear elasticity of a material under tensile stress, quantifying stiffness in one dimension, while modulus of elasticity is a broader term encompassing various types of elastic moduli, including shear and bulk modulus. Young's modulus is defined as the ratio of tensile stress to tensile strain within the elastic limit, providing a precise measurement for materials' resistance to deformation along an axis. Understanding the distinction is critical in material science, as modulus of elasticity refers to the overall elastic response, whereas Young's modulus focuses on uniaxial stress-strain relationships.

Units and Measurement Methods

Young's modulus, a specific form of modulus of elasticity, measures the tensile stiffness of a material and is expressed in pascals (Pa) or gigapascals (GPa). The modulus of elasticity broadly refers to the ratio of stress to strain in elastic deformation, quantified using stress-strain curves from tensile or compression tests. Measurement methods for both involve applying controlled stress and recording the resulting strain, typically using extensometers or strain gauges to ensure precise accuracy.

Applications in Engineering and Materials Science

Young's modulus, a specific type of modulus of elasticity, quantifies the tensile stiffness of materials such as metals, polymers, and composites, playing a crucial role in structural engineering and materials science for stress-strain analysis. Modulus of elasticity encompasses various forms including bulk and shear modulus, essential for predicting material behavior under different loading conditions in aerospace, civil engineering, and mechanical design. Understanding these moduli enables engineers to select appropriate materials for applications like bridges, aircraft components, and flexible electronics, ensuring performance and safety standards.

Common Materials and Their Elastic Moduli

Young's modulus, a specific type of modulus of elasticity, measures tensile stiffness in materials like steel, aluminum, and rubber, with values ranging from approximately 200 GPa for steel to 0.01 GPa for rubber. The modulus of elasticity broadly describes a material's resistance to elastic deformation under various stress states, encompassing tensile, compressive, and shear stresses. Common engineering materials exhibit diverse elastic moduli: concrete typically has a modulus around 30 GPa, while glass ranges between 50-90 GPa, reflecting their different internal bonding and structural characteristics.

Importance in Structural Analysis

Young's modulus and modulus of elasticity are often used interchangeably to describe a material's stiffness, representing the ratio of tensile stress to tensile strain within the linear elastic region. Young's modulus is crucial in structural analysis for predicting deformation and ensuring the integrity of beams, columns, and other load-bearing elements under applied forces. Accurate knowledge of this modulus allows engineers to design structures that can withstand stresses without excessive deformation or failure.

Factors Affecting Elastic Modulus Values

Young's modulus, a specific type of modulus of elasticity, measures tensile stiffness in materials under uniaxial stress, while the modulus of elasticity can refer to various moduli describing material stiffness under different loading conditions. Factors affecting elastic modulus values include temperature, which typically decreases modulus by increasing atomic vibrations; strain rate, where higher rates can increase measured stiffness; and material composition, such as impurities or grain size, altering internal bonding and structural integrity. Microstructural features like dislocations, phase distribution, and crystallographic texture also significantly influence the elastic modulus by modifying a material's resistance to elastic deformation.

Conclusion: Choosing the Right Modulus

Young's modulus and modulus of elasticity both describe a material's stiffness but are often used interchangeably in engineering contexts due to their equivalent numerical values for linear elastic materials. Selecting the appropriate modulus depends on the material type and deformation behavior, with Young's modulus applying primarily to tensile or compressive stress along one axis, while the broader term modulus of elasticity can encompass shear and bulk moduli for different loading conditions. For precise material characterization and accurate engineering calculations, understanding the specific mechanical context ensures the correct moduli selection, optimizing structural performance and material efficiency.

Young’s modulus Infographic

libterm.com

libterm.com