A lap joint is a common woodworking or metalworking technique where two pieces overlap and are fastened together, providing strength and stability. This joint is widely used in construction, framing, and fabrication due to its simplicity and durability. Discover how lap joints can improve Your projects by exploring the full article.

Table of Comparison

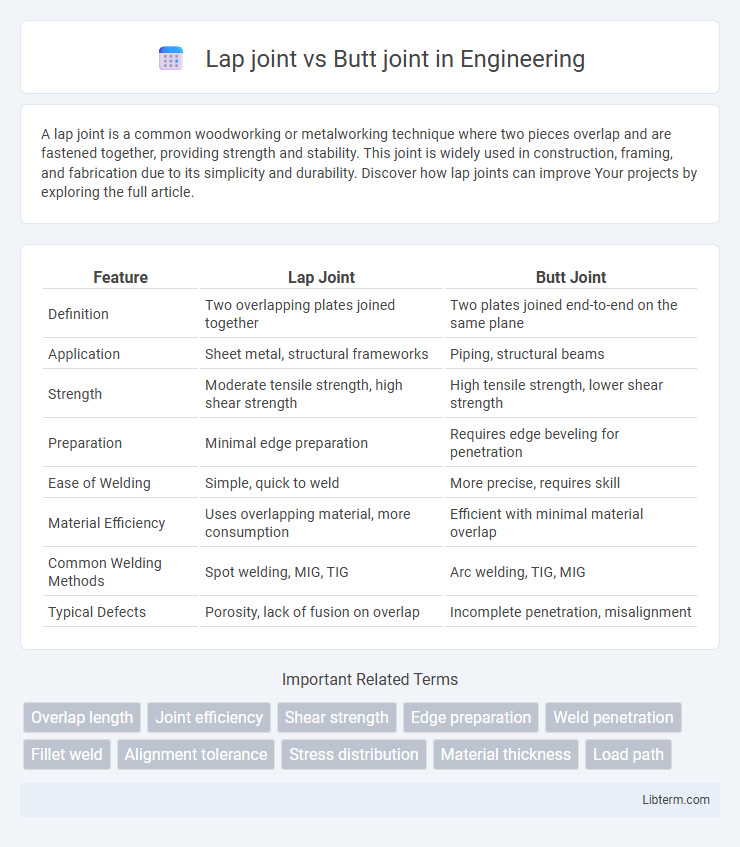

| Feature | Lap Joint | Butt Joint |

|---|---|---|

| Definition | Two overlapping plates joined together | Two plates joined end-to-end on the same plane |

| Application | Sheet metal, structural frameworks | Piping, structural beams |

| Strength | Moderate tensile strength, high shear strength | High tensile strength, lower shear strength |

| Preparation | Minimal edge preparation | Requires edge beveling for penetration |

| Ease of Welding | Simple, quick to weld | More precise, requires skill |

| Material Efficiency | Uses overlapping material, more consumption | Efficient with minimal material overlap |

| Common Welding Methods | Spot welding, MIG, TIG | Arc welding, TIG, MIG |

| Typical Defects | Porosity, lack of fusion on overlap | Incomplete penetration, misalignment |

Introduction to Lap Joint and Butt Joint

Lap joints and butt joints are fundamental techniques used in welding and metal fabrication for connecting two pieces of material. A lap joint involves overlapping two workpieces and joining them along the overlapping section, providing increased surface area for weld strength. In contrast, a butt joint aligns two pieces end-to-end or edge-to-edge without overlap, typically requiring precise edge preparation to ensure strong, seamless weld integrity.

Definition of Lap Joint

A lap joint is a type of joint where two overlapping pieces of material are fastened together, commonly used in woodworking, metalworking, and welding for enhanced strength and surface area contact. Unlike a butt joint where two pieces meet end to end, the lap joint allows for a larger bonding area, improving load distribution and resistance to shear forces. This joint is ideal for applications requiring durability and alignment accuracy, such as in structural frames and mechanical assemblies.

Definition of Butt Joint

A butt joint is a type of joint where two pieces of material are joined end-to-end without overlapping, aligning their edges in the same plane for a flush connection. Commonly used in welding and woodworking, butt joints provide a straightforward bond but may require reinforcement for added strength. This joint contrasts with a lap joint, where one piece overlaps another, offering increased surface area and strength.

Key Differences Between Lap Joint and Butt Joint

Lap joints overlap two workpieces, providing increased strength and surface area, while butt joints align two pieces end-to-end without overlap, resulting in a flush finish. Lap joints distribute stress over a larger area, making them ideal for load-bearing structures, whereas butt joints rely heavily on weld quality for strength due to the direct edge-to-edge contact. The choice between lap and butt joints depends on factors like application requirements, material thickness, and desired aesthetic outcomes.

Strength Comparison: Lap Joint vs Butt Joint

Lap joints provide greater strength than butt joints due to their increased surface area for bonding or welding, which distributes stress more evenly. Butt joints tend to concentrate stress along the weld line, making them more prone to failure under heavy loads. Structural applications demanding high tensile and shear strength often prefer lap joints for their superior load-bearing capacity.

Applications of Lap Joint

Lap joints are widely used in woodworking and metal fabrication for creating strong, overlapping connections in frames, furniture, and structural components. Common applications include cabinet making, car frame assembly, and sheet metal work, where enhanced surface area improves adhesive or weld strength. Their ability to distribute load evenly makes lap joints ideal for stress-resistant constructions in both lightweight and heavy-duty projects.

Applications of Butt Joint

Butt joints are widely used in welding, woodworking, and metal fabrication for creating strong, flush connections between two components aligned in the same plane. They are essential in pipe construction, frame building, and structural steelwork where smooth surfaces and load-bearing capability are critical. The simplicity and versatility of butt joints make them ideal for automated production processes in automotive and aerospace industries.

Advantages of Lap Joint

Lap joints provide superior strength and load distribution by overlapping materials, reducing stress concentration compared to butt joints. They offer easier alignment and assembly, making them ideal for applications requiring enhanced rigidity and durability. Their design improves resistance to shear forces and enhances overall joint stability in structural and mechanical components.

Advantages of Butt Joint

Butt joints offer a clean and seamless appearance, making them ideal for applications where aesthetics are important. They provide efficient load distribution along the joint, enhancing structural strength in various materials such as metal and wood. The simplicity of butt joint fabrication reduces production time and cost, especially in automated manufacturing processes.

Choosing Between Lap Joint and Butt Joint

Choosing between a lap joint and a butt joint depends on application requirements such as strength, alignment, and material thickness. Lap joints provide greater strength and resistance to shear forces by overlapping materials, making them ideal for structural or heavy-duty tasks. Butt joints offer a cleaner, flush finish suitable for thinner materials or applications where aesthetics and minimal joint thickness are priorities.

Lap joint Infographic

libterm.com

libterm.com