Unified thread technology streamlines complex processing by combining multiple threads into a single, efficient execution path, enhancing performance and resource management. This approach reduces context switching and synchronization overhead, making applications run smoother and faster. Discover how unified thread can optimize your system by reading the full article.

Table of Comparison

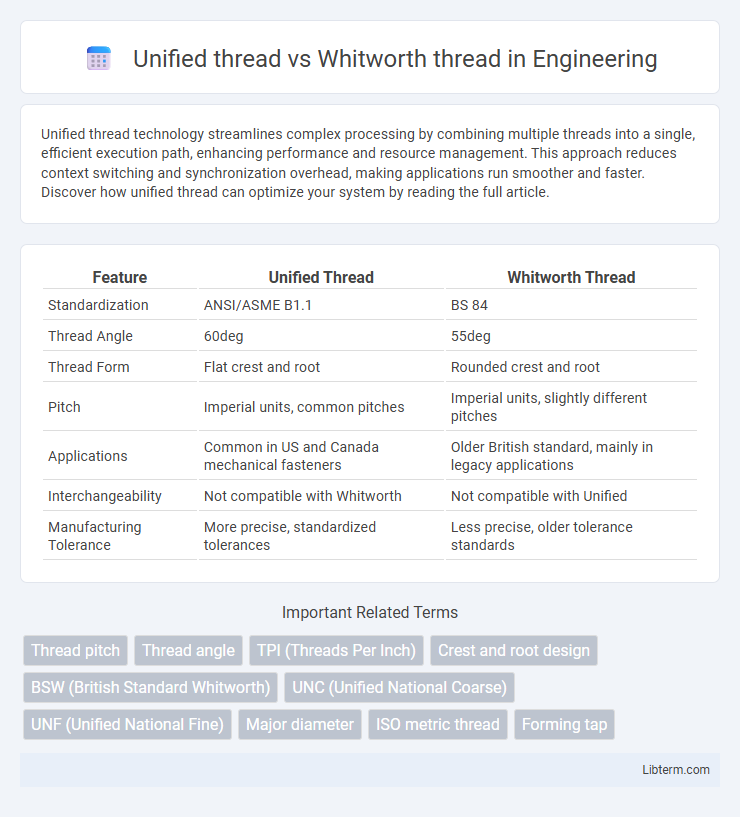

| Feature | Unified Thread | Whitworth Thread |

|---|---|---|

| Standardization | ANSI/ASME B1.1 | BS 84 |

| Thread Angle | 60deg | 55deg |

| Thread Form | Flat crest and root | Rounded crest and root |

| Pitch | Imperial units, common pitches | Imperial units, slightly different pitches |

| Applications | Common in US and Canada mechanical fasteners | Older British standard, mainly in legacy applications |

| Interchangeability | Not compatible with Whitworth | Not compatible with Unified |

| Manufacturing Tolerance | More precise, standardized tolerances | Less precise, older tolerance standards |

Introduction to Thread Standards

Unified Thread Standard (UTS) and Whitworth thread represent two primary screw thread systems used globally. UTS, developed in the early 20th century, is prominent in the United States and follows a 60-degree thread angle with flat roots and crests. Whitworth thread, created in 1841, features a 55-degree thread angle with rounded roots and crests, often used in British engineering and older machinery.

Historical Development of Unified and Whitworth Threads

Whitworth threads, developed in 1841 by Joseph Whitworth, were the first standardized screw thread system, featuring a 55-degree thread angle and widely adopted in British engineering. The Unified Thread Standard (UTS) was created in 1948 through collaboration between the United States, the United Kingdom, and Canada to replace Whitworth threads with a 60-degree thread angle and finer pitch options for improved compatibility in aerospace and military applications. This shift facilitated international standardization and streamlined manufacturing processes across allied nations during and after World War II.

Design Characteristics of Unified Threads

Unified threads feature a 60-degree thread angle with flat crests and roots, promoting better load distribution and easier manufacturing compared to the 55-degree angle with rounded crests and roots of Whitworth threads. The Unified Thread Standard (UTS) uses a symmetrical V-shaped profile with a thread pitch governed by the number of threads per inch (TPI), facilitating compatibility with U.S. and Canadian engineering practices. Design characteristics emphasize standardization in form, allowing efficient interchangeability and strength optimized for high-stress mechanical connections.

Design Characteristics of Whitworth Threads

Whitworth threads feature a 55-degree thread angle with rounded crests and roots, designed to reduce stress concentration and improve fatigue resistance compared to the 60-degree angle of Unified threads. The rounded profile of Whitworth threads enhances load distribution and minimizes the risk of cracking under cyclic loads. Dimensions are standardized in inches with coarse and fine series, emphasizing robustness and durability in heavy-duty applications.

Dimensional Differences: Unified vs Whitworth

Unified threads use a 60-degree thread angle with flat crests and roots, while Whitworth threads have a 55-degree thread angle with rounded crests and roots. The pitch and thread depth also differ, with Unified threads conforming to standard pitch sizes in inches (e.g., 24 TPI for 1/4"), contrasting Whitworth pitches that are less common and usually coarser. Dimensional differences impact compatibility, as Unified threads follow ANSI/ASME standards prevalent in the US, whereas Whitworth threads adhere to British Standards (BS), mostly used in older or British-manufactured equipment.

Mechanical Performance Comparison

Unified thread forms exhibit superior tensile strength and fatigue resistance due to their finer pitch and roots designed to reduce stress concentration, making them ideal for high-stress mechanical applications. Whitworth threads, characterized by a 55-degree thread angle and rounded roots, offer better resistance to wear and corrosion in softer materials, but generally provide lower load-bearing capacity compared to Unified threads. The choice between Unified and Whitworth threads depends on the mechanical performance requirements, with Unified threads preferred for precision engineering and high-load assemblies.

Applications and Industry Usage

Unified threads dominate in North American applications, including automotive, aerospace, and machinery industries, due to their standardized 60-degree thread angle enhancing compatibility with modern fasteners. Whitworth threads, with a 55-degree thread angle, are prevalent in British and Commonwealth countries, commonly used in vintage machinery, plumbing, and railway systems where historical standards persist. The choice between Unified and Whitworth threads impacts tooling, maintenance, and interoperability within specific industrial contexts.

Interchangeability and Compatibility Issues

Unified threads and Whitworth threads differ significantly in pitch and angle, making interchangeability impractical without risking fit and strength. Unified threads use a 60-degree angle and are common in American and international applications, while Whitworth threads feature a 55-degree angle primarily in older British machinery. Compatibility issues arise when substituting one for the other, leading to potential cross-threading, weakened joints, and mechanical failure due to mismatched thread geometry.

Advantages and Disadvantages of Each Thread Type

Unified threads offer a standardized profile with a 60-degree angle, providing superior compatibility in North American markets and easier interchangeability for fasteners. Whitworth threads, featuring a 55-degree angle with rounded crests and roots, provide better resistance to stress concentration and improved load distribution, making them ideal for older British machinery. Unified threads may suffer from less efficient load bearing compared to Whitworth's rounded design, while Whitworth threads are less common globally, causing compatibility issues in international applications.

Selecting the Right Thread Standard for Your Project

Selecting the right thread standard depends on the application requirements, compatibility, and regional standards. Unified threads, commonly used in North America, feature a 60-degree thread angle and standardized pitch sizes, making them ideal for projects requiring interchangeability in US and Canada markets. Whitworth threads, with their 55-degree thread angle and rounded crests, are preferred in British and Commonwealth countries, offering better load distribution and resistance to wear in older or traditional machinery applications.

Unified thread Infographic

libterm.com

libterm.com