Wave resistance significantly impacts the efficiency of vessels moving through water by creating energy loss due to wave formation. Reducing wave resistance can improve fuel efficiency and speed, making hull design optimization crucial in naval engineering. Explore the article to understand how wave resistance affects your vessel's performance and what innovations help minimize it.

Table of Comparison

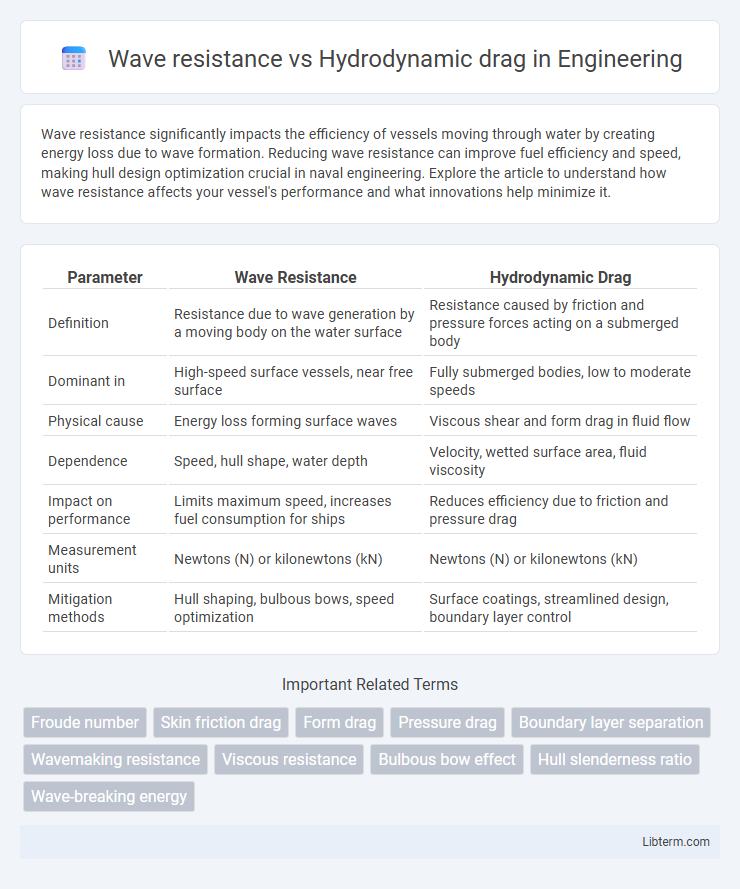

| Parameter | Wave Resistance | Hydrodynamic Drag |

|---|---|---|

| Definition | Resistance due to wave generation by a moving body on the water surface | Resistance caused by friction and pressure forces acting on a submerged body |

| Dominant in | High-speed surface vessels, near free surface | Fully submerged bodies, low to moderate speeds |

| Physical cause | Energy loss forming surface waves | Viscous shear and form drag in fluid flow |

| Dependence | Speed, hull shape, water depth | Velocity, wetted surface area, fluid viscosity |

| Impact on performance | Limits maximum speed, increases fuel consumption for ships | Reduces efficiency due to friction and pressure drag |

| Measurement units | Newtons (N) or kilonewtons (kN) | Newtons (N) or kilonewtons (kN) |

| Mitigation methods | Hull shaping, bulbous bows, speed optimization | Surface coatings, streamlined design, boundary layer control |

Introduction to Wave Resistance and Hydrodynamic Drag

Wave resistance arises when a vessel moves through water, generating waves that consume energy and reduce propulsion efficiency. Hydrodynamic drag encompasses all resistive forces acting on a hull, including frictional drag, form drag, and wave resistance, affecting overall vessel performance. Understanding the balance and interaction between wave resistance and hydrodynamic drag is crucial for optimizing ship design and fuel economy.

Defining Wave Resistance

Wave resistance is a component of hydrodynamic drag specifically caused by the creation of waves as a vessel moves through water, representing the energy lost to wave formation. Unlike viscous drag, which stems from friction between the ship's hull and water, wave resistance increases significantly at higher speeds and depends on hull shape and displacement. Minimizing wave resistance is crucial in naval architecture to enhance fuel efficiency and improve overall vessel performance.

Understanding Hydrodynamic Drag

Hydrodynamic drag refers to the resistance experienced by an object moving through water, caused by the viscous friction between the fluid and the object's surface. It consists primarily of two components: skin friction drag, resulting from the water's viscous effects along the hull, and form drag, which arises due to pressure differences around the object's shape. Minimizing hydrodynamic drag is critical in naval architecture and marine engineering to improve vessel efficiency, fuel economy, and speed.

Key Differences Between Wave Resistance and Hydrodynamic Drag

Wave resistance primarily occurs when a vessel moves at or near the water surface, generating waves that consume energy and reduce speed efficiency. Hydrodynamic drag encompasses both wave resistance and viscous resistance, the latter arising from friction between the hull surface and water, impacting submerged portions of a vessel. Key differences highlight that wave resistance dominates at high speeds with surface interaction, while hydrodynamic drag includes all forms of resistance acting on the hull, influencing fuel consumption and design optimization.

Factors Influencing Wave Resistance

Wave resistance is primarily influenced by vessel speed, hull shape, and water depth, causing energy loss due to wave creation at the water surface. Sharp hull forms and shallow water can increase wave amplitude, leading to higher wave resistance compared to hydrodynamic drag, which results from friction and pressure differences on the hull. Optimizing hull design to reduce wave generation is critical for minimizing overall resistance and improving vessel efficiency.

Elements Affecting Hydrodynamic Drag

Hydrodynamic drag comprises viscous drag and pressure drag, influenced primarily by factors such as hull shape, surface roughness, and flow velocity. Elements like boundary layer thickness, Reynolds number, and water viscosity significantly affect the magnitude of viscous drag, while hull form and flow separation impact pressure drag. Optimizing hull design by minimizing wetted surface area and ensuring smooth finishes reduces hydrodynamic drag, enhancing vessel efficiency against wave resistance.

Impact on Vessel Performance

Wave resistance significantly affects vessel performance by increasing energy consumption as the hull generates waves during movement, particularly at higher speeds. Hydrodynamic drag, caused by friction and pressure differences along the hull's surface, reduces overall propulsion efficiency and limits maximum speed. Minimizing both wave resistance and hydrodynamic drag is crucial for enhancing fuel efficiency and achieving optimal vessel maneuverability.

Measurement and Calculation Methods

Wave resistance and hydrodynamic drag are quantified using specialized measurement and calculation techniques critical for naval architecture and fluid dynamics. Wave resistance is typically evaluated through towing tank experiments and computational fluid dynamics (CFD) simulations that analyze the energy dissipated in wave generation at the hull-water interface, using metrics like wave pattern analysis and wave profile measurements. Hydrodynamic drag is measured by isolating viscous and form drag components, employing methods such as drag balance tests in towing tanks and advanced CFD modeling with turbulence models to calculate shear stress distributions and pressure drag on submerged surfaces.

Strategies for Reducing Wave Resistance and Hydrodynamic Drag

Reducing wave resistance involves optimizing hull shapes to minimize wave generation by adopting bulbous bows or slender hull forms that streamline water flow and reduce energy loss. Hydrodynamic drag can be decreased through surface treatments such as low-friction coatings, air lubrication systems, and regular hull cleaning to prevent biofouling which increases frictional resistance. Implementing advanced computational fluid dynamics (CFD) simulations enables precise design modifications to balance wave resistance and hydrodynamic drag for enhanced vessel efficiency.

Future Trends in Marine Hydrodynamics

Future trends in marine hydrodynamics emphasize reducing wave resistance and hydrodynamic drag through advanced computational fluid dynamics (CFD) and machine learning algorithms. Innovations in hull design, such as biomimetic surfaces and adaptive coatings, aim to minimize energy loss by optimizing flow patterns and suppressing turbulent wake formation. The integration of real-time sensor data with AI-driven control systems offers dynamic resistance management, promising significant improvements in fuel efficiency and vessel performance.

Wave resistance Infographic

libterm.com

libterm.com