Fatigue strength measures a material's ability to withstand repeated cyclic stresses without failure, crucial for ensuring long-term durability in structural components. Understanding fatigue strength helps you select appropriate materials for applications subjected to fluctuating loads, preventing unexpected breakdowns. Explore the rest of this article to learn how to evaluate and improve fatigue strength in your designs.

Table of Comparison

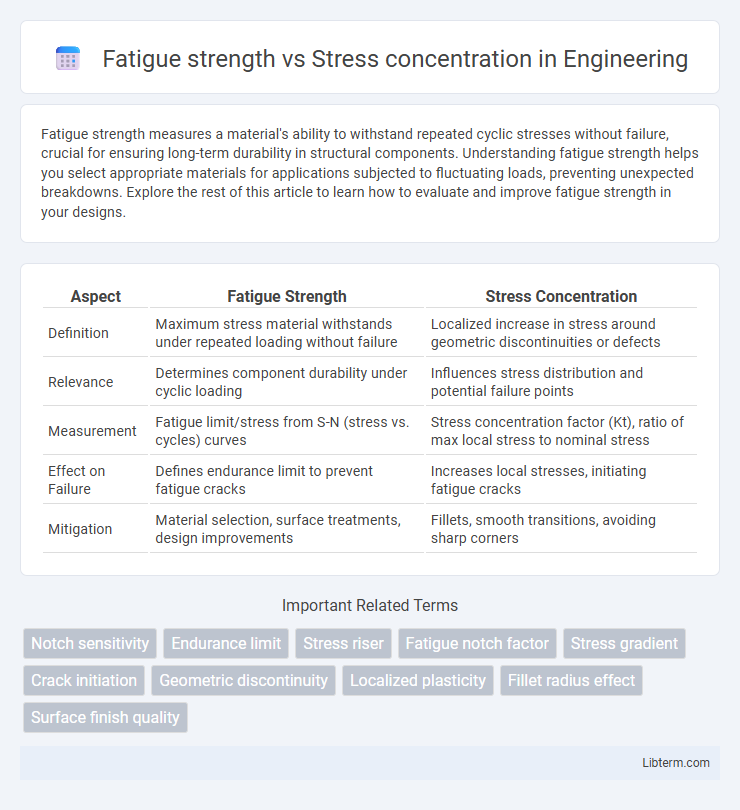

| Aspect | Fatigue Strength | Stress Concentration |

|---|---|---|

| Definition | Maximum stress material withstands under repeated loading without failure | Localized increase in stress around geometric discontinuities or defects |

| Relevance | Determines component durability under cyclic loading | Influences stress distribution and potential failure points |

| Measurement | Fatigue limit/stress from S-N (stress vs. cycles) curves | Stress concentration factor (Kt), ratio of max local stress to nominal stress |

| Effect on Failure | Defines endurance limit to prevent fatigue cracks | Increases local stresses, initiating fatigue cracks |

| Mitigation | Material selection, surface treatments, design improvements | Fillets, smooth transitions, avoiding sharp corners |

Understanding Fatigue Strength

Fatigue strength is the maximum stress a material can withstand for a specified number of cycles without failure, significantly influenced by stress concentration factors such as notches, grooves, or sudden changes in geometry. Stress concentrations create localized increases in stress, reducing the effective fatigue strength and accelerating crack initiation under cyclic loading. Accurate assessment of fatigue strength requires incorporating stress concentration effects to predict material durability and prevent premature failure in engineering components.

Defining Stress Concentration

Stress concentration refers to localized increases in stress around geometric discontinuities such as holes, notches, or sharp corners, which can significantly reduce the fatigue strength of a material. These stress risers cause uneven stress distribution, promoting crack initiation and propagation under cyclic loading conditions. Understanding and mitigating stress concentration is crucial for improving fatigue performance and preventing premature structural failure.

Mechanisms of Fatigue Failure

Fatigue strength decreases significantly in the presence of stress concentration due to localized increases in stress that initiate micro-cracks at notches or geometric discontinuities. These micro-cracks propagate under cyclic loading through mechanisms such as slip band formation, persistent slip bands, and crack tip plasticity, accelerating fatigue failure. The interaction between stress concentration and material microstructure dictates the rate of crack initiation and growth, crucial for predicting component lifespan under repeated stress cycles.

Causes of Stress Concentration in Materials

Stress concentration in materials arises primarily from geometric irregularities such as sharp corners, notches, holes, and sudden changes in cross-sectional area, which interrupt the uniform flow of stress. These localized features amplify the stress beyond the nominal applied load, significantly reducing fatigue strength by initiating microcracks at elevated stress points. Material defects like inclusions, voids, and surface roughness further exacerbate stress concentration effects, accelerating fatigue failure under cyclic loading conditions.

Relationship Between Fatigue Strength and Stress Concentration

Fatigue strength decreases significantly as stress concentration increases, due to localized stress intensification at notches, cracks, or geometric discontinuities. The presence of stress concentration factors (Kt) amplifies the nominal stress, accelerating crack initiation and propagation, which reduces the material's resistance to cyclic loading. Engineering designs incorporating stress concentration must account for reduced fatigue life by applying notch sensitivity and fatigue notch factor adjustments to accurately predict fatigue strength.

Geometrical Effects on Fatigue Performance

Geometrical features such as notches, holes, and sharp corners significantly influence fatigue strength by creating localized stress concentrations that reduce the material's ability to withstand cyclic loading. Stress concentration factors (SCFs) quantify these effects, with higher SCFs leading to increased initiation sites for fatigue cracks and decreased fatigue life. Designing smooth transitions and minimizing abrupt changes in cross-sectional geometry effectively improve fatigue performance by lowering stress concentrations and distributing stresses more uniformly.

Methods to Reduce Stress Concentration

Fatigue strength significantly decreases near stress concentration areas due to localized stress intensification, demanding effective mitigation methods. Techniques such as adding fillets or radii to sharp corners, using material treatments like shot peening, and employing surface coatings help distribute stress more evenly and reduce the risk of crack initiation. Optimizing geometric design and applying residual compressive stress are critical strategies to enhance fatigue life in components subjected to cyclic loading.

Material Selection for Enhanced Fatigue Strength

Fatigue strength significantly decreases in the presence of stress concentrations such as notches or cracks, making material selection crucial for applications prone to cyclic loading. Materials with high fracture toughness and intrinsic resistance to crack initiation, such as advanced high-strength steels or titanium alloys, enhance fatigue performance by mitigating stress concentration effects. Optimizing microstructure and employing surface treatments like shot peening further improve fatigue strength by reducing stress concentration severity and delaying crack propagation.

Testing and Evaluation of Fatigue Strength

Testing fatigue strength involves cyclic loading of materials to determine endurance limits under repeated stress, while stress concentration significantly impacts these results by creating localized increases in stress that accelerate crack initiation. Evaluation techniques use standardized specimens with introduced notches or geometric discontinuities to simulate stress concentrators, allowing precise measurement of fatigue life reduction. Advanced methods like strain gauging and finite element analysis complement experimental data to quantify the effect of stress concentration factors (Kt) on fatigue performance.

Engineering Design Strategies for Fatigue and Stress Concentration

Engineering design strategies for fatigue and stress concentration emphasize optimizing geometrical features to minimize stress risers, such as smooth fillets and gradual transitions, which significantly enhance fatigue strength. Material selection with high fracture toughness and the use of surface treatments like shot peening improve resistance to crack initiation at stress concentration zones. Incorporating finite element analysis (FEA) enables precise identification of critical stress concentration factors, allowing targeted reinforcements that effectively mitigate fatigue failure risks.

Fatigue strength Infographic

libterm.com

libterm.com