Manual welding requires skilled hand coordination and precise control of the welding torch or electrode to create strong, reliable joints. Understanding the correct techniques and safety measures enhances the quality and durability of your welds. Explore the rest of this article to master manual welding and improve your craftsmanship.

Table of Comparison

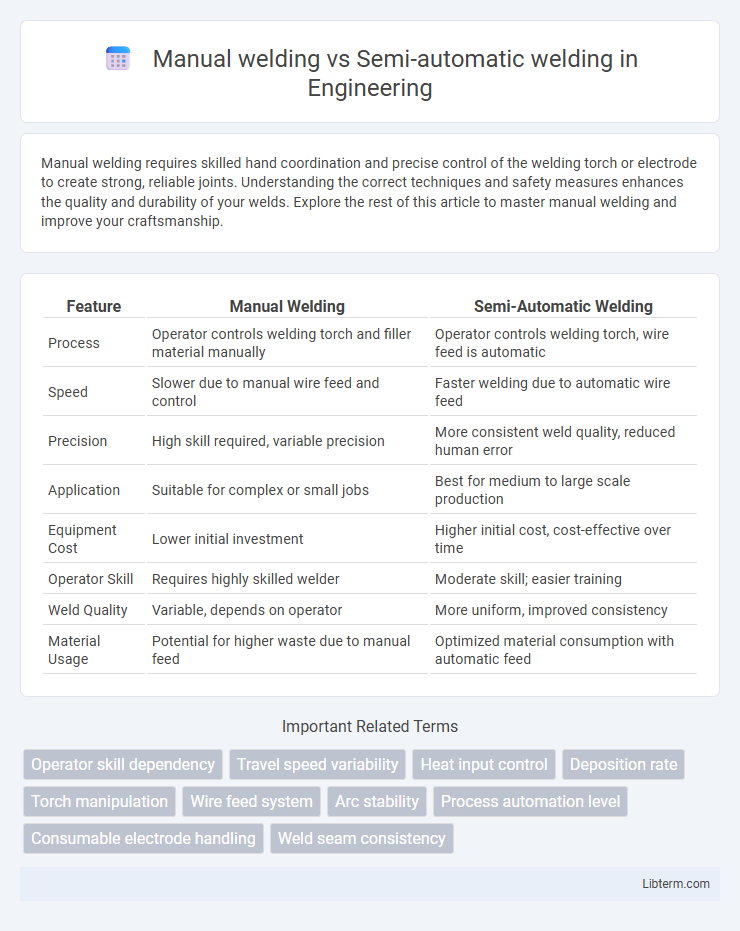

| Feature | Manual Welding | Semi-Automatic Welding |

|---|---|---|

| Process | Operator controls welding torch and filler material manually | Operator controls welding torch, wire feed is automatic |

| Speed | Slower due to manual wire feed and control | Faster welding due to automatic wire feed |

| Precision | High skill required, variable precision | More consistent weld quality, reduced human error |

| Application | Suitable for complex or small jobs | Best for medium to large scale production |

| Equipment Cost | Lower initial investment | Higher initial cost, cost-effective over time |

| Operator Skill | Requires highly skilled welder | Moderate skill; easier training |

| Weld Quality | Variable, depends on operator | More uniform, improved consistency |

| Material Usage | Potential for higher waste due to manual feed | Optimized material consumption with automatic feed |

Introduction to Manual and Semi-automatic Welding

Manual welding relies on the welder's skill to control the welding torch and filler material, offering flexibility for complex and precise tasks. Semi-automatic welding uses a mechanized feed of filler wire while the operator guides the torch, enhancing efficiency and consistency in medium to large-scale projects. Both methods serve distinct industrial needs, with manual welding favored for custom jobs and semi-automatic welding preferred for repetitive production.

Definition and Overview of Manual Welding

Manual welding, also known as Shielded Metal Arc Welding (SMAW) or stick welding, involves an operator manually controlling the welding torch and feeding the electrode to create a weld. It requires skillful handling to maintain the correct arc length and angle, ensuring proper fusion of metals. This technique is widely used in construction, repair, and maintenance due to its versatility and portability.

Understanding Semi-automatic Welding Techniques

Semi-automatic welding techniques involve the controlled feeding of filler material into the weld pool while the welder guides the torch, enhancing precision and productivity compared to manual welding. Processes such as MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding utilize semi-automatic methods to achieve consistent weld quality with increased speed and reduced operator fatigue. Understanding key parameters like wire feed speed, voltage settings, and shielding gas composition is essential for optimizing semi-automatic welding performance in industrial applications.

Key Differences Between Manual and Semi-automatic Welding

Manual welding requires the operator to control the electrode, filler material, and welding speed entirely by hand, offering greater versatility for complex shapes but demanding higher skill and precision. Semi-automatic welding uses a mechanized feed for the electrode or filler wire while the operator guides the welding torch, improving consistency and speed in repetitive tasks. Key differences include manual welding's reliance on operator skill and flexibility versus semi-automatic welding's enhanced efficiency and uniformity in production environments.

Equipment and Tools Required for Each Method

Manual welding requires basic equipment such as welding machines, electrodes, protective gear, and hand tools, emphasizing skill and precision from the operator. Semi-automatic welding involves more advanced machinery, including wire feeders, welding guns, and automated controls, reducing manual intervention. The increased automation in semi-automatic welding enhances efficiency and consistency, while manual welding offers greater flexibility for intricate or customized tasks.

Advantages of Manual Welding

Manual welding offers greater control and precision, allowing skilled welders to adapt techniques to complex or irregular joints, which is ideal for customized or intricate projects. It requires minimal equipment investment compared to semi-automatic systems, making it more accessible for small-scale operations or repairs. The flexibility in electrode choice and welding positions enhances its applicability across a wide range of materials and thicknesses.

Benefits of Semi-automatic Welding

Semi-automatic welding offers enhanced consistency and precision, reducing human errors compared to manual welding methods. Increased productivity results from faster welding speeds and improved control over the welding process, making it ideal for industrial applications. The use of semi-automatic systems also minimizes fatigue for operators, leading to higher quality welds and improved workplace safety.

Common Applications and Industries

Manual welding is widely used in construction, shipbuilding, and repair industries where high precision and customization are essential. Semi-automatic welding, often employed in automotive manufacturing, pipeline construction, and heavy equipment fabrication, enhances productivity by combining operator control with mechanized wire feeding. Both methods serve key roles in structural steelwork, aerospace, and metal fabrication sectors depending on project scale and production speed requirements.

Challenges and Limitations of Both Methods

Manual welding poses challenges such as inconsistent weld quality due to operator skill variability and slower production rates, while limitations include increased fatigue and higher risk of defects in complex joints. Semi-automatic welding offers improved speed and consistency but struggles with limited flexibility in handling intricate weld geometries and requires higher initial investment and maintenance. Both methods face challenges in achieving optimal precision and efficiency in highly automated or mass-production environments.

Choosing the Right Welding Method for Your Needs

Manual welding offers precise control and flexibility, making it ideal for customized projects or complex joints, especially in repair work and small-scale fabrication. Semi-automatic welding increases productivity and ensures consistent weld quality, suitable for high-volume manufacturing and repetitive tasks. Selecting the right welding method depends on factors such as project scale, skill level, desired speed, and the specific material being welded.

Manual welding Infographic

libterm.com

libterm.com