Plug welds provide a strong and efficient method for joining two overlapping metal pieces by filling a pre-drilled hole with weld material, eliminating the need for edge access. This technique enhances structural integrity and is commonly used in automotive and construction industries to create durable, concealed joints. Explore the rest of the article to understand how plug welds can optimize your metal fabrication projects.

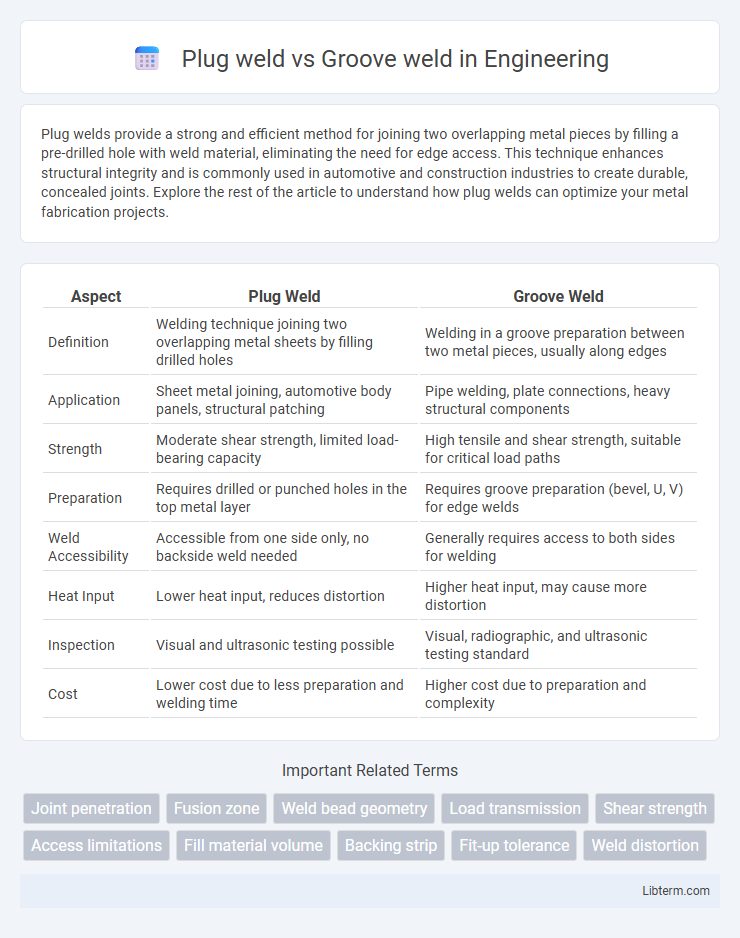

Table of Comparison

| Aspect | Plug Weld | Groove Weld |

|---|---|---|

| Definition | Welding technique joining two overlapping metal sheets by filling drilled holes | Welding in a groove preparation between two metal pieces, usually along edges |

| Application | Sheet metal joining, automotive body panels, structural patching | Pipe welding, plate connections, heavy structural components |

| Strength | Moderate shear strength, limited load-bearing capacity | High tensile and shear strength, suitable for critical load paths |

| Preparation | Requires drilled or punched holes in the top metal layer | Requires groove preparation (bevel, U, V) for edge welds |

| Weld Accessibility | Accessible from one side only, no backside weld needed | Generally requires access to both sides for welding |

| Heat Input | Lower heat input, reduces distortion | Higher heat input, may cause more distortion |

| Inspection | Visual and ultrasonic testing possible | Visual, radiographic, and ultrasonic testing standard |

| Cost | Lower cost due to less preparation and welding time | Higher cost due to preparation and complexity |

Introduction to Plug Welds and Groove Welds

Plug welds are circular welds used to join two overlapping metal pieces by filling a hole in the top piece, creating a strong bond without the need for edge preparation. Groove welds involve welding along the edges of two components, with various groove shapes such as V, U, or J, designed for full penetration and high-strength joints suitable for thick materials. Both weld types serve distinct structural purposes in fabrication, with plug welds offering quick attachment and groove welds providing robust, load-bearing connections.

Definition and Overview of Plug Welds

Plug welds involve joining two overlapping metal surfaces by filling a pre-drilled hole in the top metal piece with weld material, creating a mechanical and metallurgical bond. This technique is primarily used to attach sheets or components without edge preparation, offering a strong, localized weld suitable for joining thin materials. Groove welds, by contrast, join edges prepared with grooves to ensure deep penetration and strong fusion, commonly used for thicker metals requiring full joint strength.

Definition and Overview of Groove Welds

Groove welds involve joining two metal parts by filling a groove or gap between their edges, commonly used for butt joints to ensure deep penetration and strong mechanical bonding. This weld type includes variations such as V-groove, U-groove, and J-groove welds, each designed to optimize weld strength and accessibility depending on the joint configuration. Groove welds provide superior load-carrying capacity and are essential in structural applications where full joint penetration and high integrity are required.

Key Differences Between Plug Welds and Groove Welds

Plug welds involve filling a pre-drilled hole in one metal piece to join it to another, typically used for overlapping sheets, while groove welds create a fusion along the edges of two metal parts prepared with grooves for deeper penetration. Groove welds provide stronger joints suitable for structural applications due to their enhanced depth of fusion and stress distribution, whereas plug welds offer faster, simpler joining ideal for non-critical or lightweight assemblies. The choice between plug weld and groove weld depends on factors like joint strength requirements, accessibility, and the thickness of the materials involved.

Strength and Performance Comparison

Plug welds provide localized joining strength, ideal for overlapping thin materials, but generally exhibit lower tensile strength compared to groove welds due to their limited weld area. Groove welds penetrate deeper and cover more surface area, offering superior load-bearing capacity and better fatigue resistance in structural applications. Performance-wise, groove welds are preferred for critical joints requiring maximum strength, while plug welds serve well in applications with moderate stress and ease of access constraints.

Applications and Use Cases

Plug welds are widely used in automotive and sheet metal industries for joining overlapping parts where access is limited to one side, providing strong shear strength in body panels and structural assemblies. Groove welds serve critical roles in pipeline construction, pressure vessels, and heavy machinery by ensuring full penetration welds that withstand high pressure and mechanical stresses. Choosing between plug weld and groove weld depends largely on material thickness, joint design, and load requirements in manufacturing or repair applications.

Advantages of Plug Welds

Plug welds offer significant advantages in sheet metal joining by providing strong localized bonding without the need for edge preparation, reducing fabrication time and costs. They allow for the welding of overlapping materials where groove welds may be impractical or require complex joint design. Plug welds also minimize distortion and are ideal for applications requiring leak-proof joints, enhancing structural integrity in automotive and aerospace manufacturing.

Advantages of Groove Welds

Groove welds provide superior strength and full joint penetration, making them ideal for critical structural applications that require high load-bearing capacity. They offer better access for inspection and quality control, reducing the risk of weld defects compared to plug welds. Groove welds also facilitate easier automation in welding processes, increasing productivity and consistency in manufacturing.

Factors for Selecting Plug Weld or Groove Weld

Selecting between plug weld and groove weld depends on factors such as material thickness, joint design, and load requirements. Plug welds are ideal for joining overlapping sheets with moderate strength needs, offering ease of access and quicker application. Groove welds provide superior strength for heavier loads and complex joint configurations, especially in thicker materials requiring thorough fusion and structural integrity.

Conclusion: Choosing the Right Welding Method

Plug welds provide efficient joining for overlapping materials with less surface preparation, ideal for sheet metal applications requiring strength and speed. Groove welds offer superior penetration and strength for thicker materials and critical structural components, ensuring weld integrity under high stress. Selecting the right welding method depends on material thickness, joint design, and load requirements to optimize performance and durability.

Plug weld Infographic

libterm.com

libterm.com