Laser welding offers precise and strong metal joining capabilities with minimal heat distortion, making it ideal for delicate or complex components across industries like automotive and aerospace. This technique uses a concentrated laser beam to create deep, narrow welds quickly and efficiently, enhancing production speed and quality. Explore the rest of this article to understand how laser welding can improve your manufacturing processes and product durability.

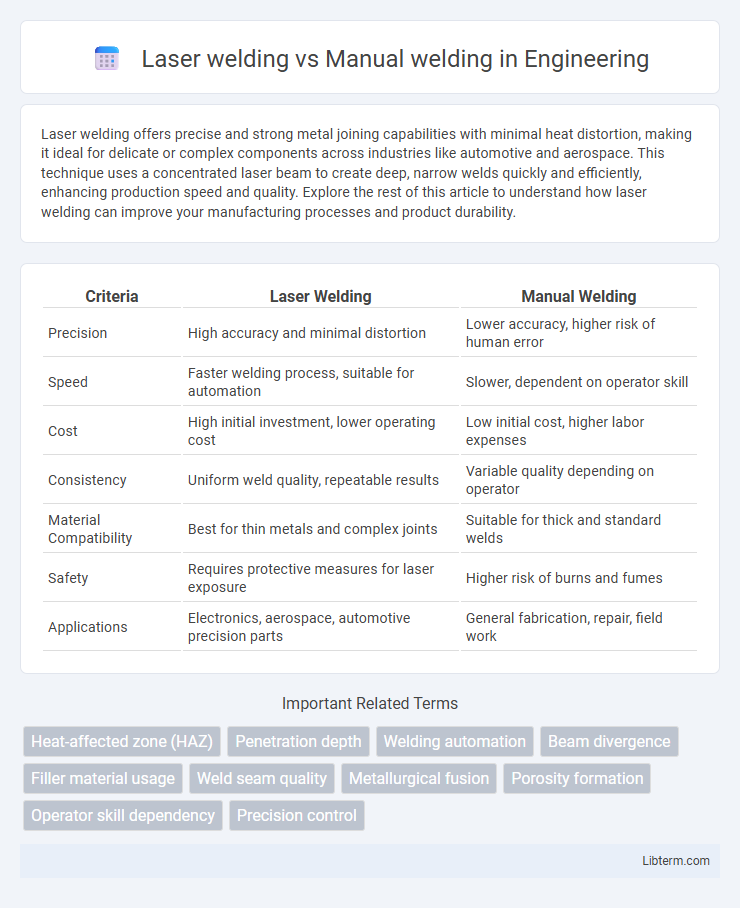

Table of Comparison

| Criteria | Laser Welding | Manual Welding |

|---|---|---|

| Precision | High accuracy and minimal distortion | Lower accuracy, higher risk of human error |

| Speed | Faster welding process, suitable for automation | Slower, dependent on operator skill |

| Cost | High initial investment, lower operating cost | Low initial cost, higher labor expenses |

| Consistency | Uniform weld quality, repeatable results | Variable quality depending on operator |

| Material Compatibility | Best for thin metals and complex joints | Suitable for thick and standard welds |

| Safety | Requires protective measures for laser exposure | Higher risk of burns and fumes |

| Applications | Electronics, aerospace, automotive precision parts | General fabrication, repair, field work |

Introduction to Laser Welding and Manual Welding

Laser welding utilizes a high-intensity laser beam to precisely fuse metal components with minimal heat distortion, enabling fast and accurate joins ideal for complex or delicate materials. Manual welding relies on a skilled welder using handheld equipment such as TIG or MIG torches to manually control the weld pool, offering flexibility in diverse applications but often resulting in slower production. Both techniques have distinct advantages depending on project requirements, with laser welding favored for automation and precision, while manual welding excels in adaptability and repair work.

Overview of Welding Processes

Laser welding offers precise, high-speed joining with minimal heat distortion and deep penetration, ideal for automated and complex applications. Manual welding relies on skilled operators to control the welding torch, providing flexibility for varying materials and thicknesses but with slower speed and increased heat-affected zones. The choice between laser and manual welding depends on production volume, material type, and required weld quality.

Precision and Accuracy Comparison

Laser welding offers superior precision and accuracy compared to manual welding due to its focused laser beam that allows for exact control of heat input and minimal distortion. The process enables consistent weld quality and repeatability by utilizing computer-controlled parameters, reducing human error inherent in manual welding. Manual welding depends heavily on the operator's skill, leading to variability in weld bead size, penetration, and alignment, which can compromise accuracy in high-precision applications.

Speed and Productivity Differences

Laser welding offers significantly faster processing times with speeds up to 20 times greater than manual welding, dramatically boosting productivity in high-volume manufacturing. Its precise, automated operation reduces cycle times and minimizes human error, leading to consistent, high-quality welds without the need for rework. Manual welding, while flexible for complex or small-batch jobs, results in slower throughput and variable productivity due to dependence on operator skill and fatigue.

Material Adaptability and Thickness

Laser welding excels in material adaptability by efficiently joining a wide range of metals, including stainless steel, aluminum, and titanium, with minimal distortion due to its precise heat control. It handles various thicknesses from ultra-thin foils of 0.1 mm to thick plates above 20 mm, making it highly versatile for complex applications. Manual welding, while flexible for different materials, often struggles with consistency and quality at extreme thicknesses, limiting its effectiveness with very thin or very thick materials.

Joint Quality and Consistency

Laser welding delivers superior joint quality with precise heat control, resulting in minimal distortion and stronger, cleaner welds compared to manual welding. Consistency in laser welding is achieved through automated, programmable processes that reduce human error and ensure uniform weld penetration and bead appearance. Manual welding often exhibits variability in joint quality due to operator skill differences and fluctuating environmental conditions.

Cost-Effectiveness and ROI

Laser welding offers higher cost-effectiveness than manual welding due to faster processing speeds, reduced labor costs, and minimal material waste, leading to significant savings in high-volume production. The initial investment in laser welding equipment is offset by improved precision, lower defect rates, and increased throughput, resulting in a shorter return on investment (ROI) period. Manual welding requires lower upfront costs but incurs higher long-term expenses from slower production, inconsistent quality, and increased rework, reducing overall ROI efficiency.

Safety Considerations and Workplace Environment

Laser welding offers enhanced safety by minimizing exposure to harmful fumes and reducing the risk of burns due to its precise, controlled heat source. Manual welding generates more hazardous fumes and presents a higher risk of eye injury and skin burns from spatter and prolonged exposure to UV radiation. Implementing proper ventilation systems, personal protective equipment (PPE) like welding helmets with UV protection, and automated safety barriers are crucial for maintaining a safe workplace environment in both welding methods.

Skills and Training Requirements

Laser welding requires specialized technical skills and advanced training in operating precise laser equipment, ensuring safety and mastery in controlling heat input to avoid material distortion. Manual welding demands hands-on experience and proficiency with various welding techniques, electrode handling, and visual inspection to achieve consistent weld quality. Training for laser welding is often more intensive and technologically focused, while manual welding relies heavily on practical skill development and craftsmanship.

Applications and Industry Use Cases

Laser welding offers precision and high speed, making it ideal for applications in the automotive and aerospace industries where intricate components and tight tolerances are essential. Manual welding remains prevalent in construction and repair sectors due to its adaptability to varied environments and lower initial equipment costs. Industries such as electronics manufacturing benefit from laser welding's minimal heat input, while shipbuilding often relies on manual welding for large-scale structural assemblies.

Laser welding Infographic

libterm.com

libterm.com