Heat treatment enhances the mechanical properties of metals by precisely controlling temperature and cooling rates to alter their microstructure. This process improves hardness, strength, ductility, and resistance to wear and corrosion, tailored to specific applications. Discover how heat treatment can optimize your materials and improve performance by reading the full article.

Table of Comparison

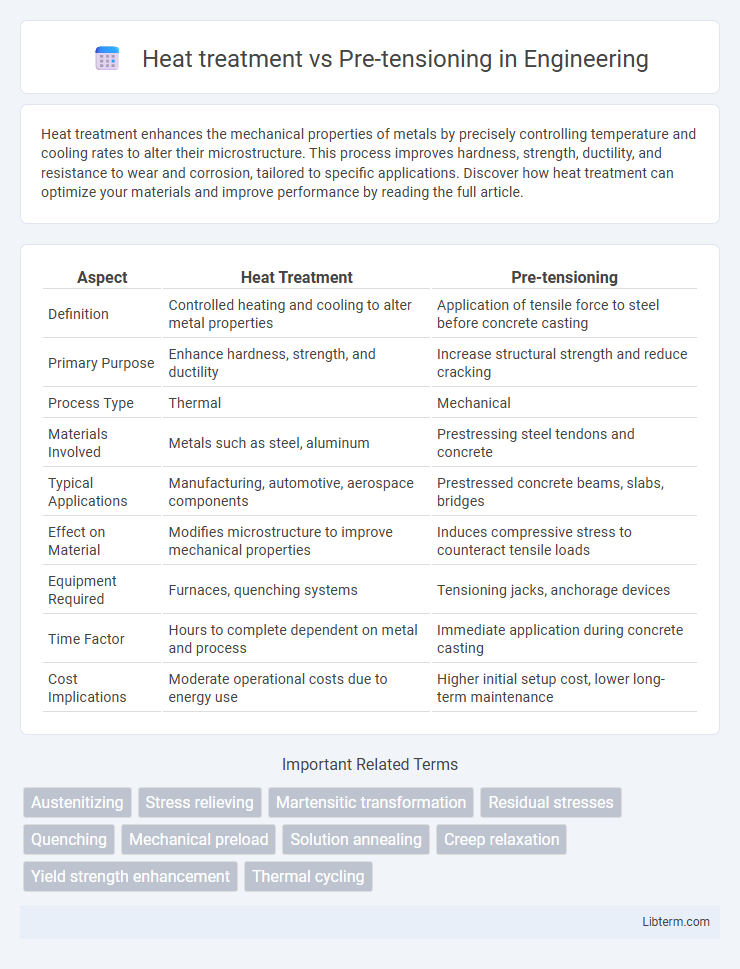

| Aspect | Heat Treatment | Pre-tensioning |

|---|---|---|

| Definition | Controlled heating and cooling to alter metal properties | Application of tensile force to steel before concrete casting |

| Primary Purpose | Enhance hardness, strength, and ductility | Increase structural strength and reduce cracking |

| Process Type | Thermal | Mechanical |

| Materials Involved | Metals such as steel, aluminum | Prestressing steel tendons and concrete |

| Typical Applications | Manufacturing, automotive, aerospace components | Prestressed concrete beams, slabs, bridges |

| Effect on Material | Modifies microstructure to improve mechanical properties | Induces compressive stress to counteract tensile loads |

| Equipment Required | Furnaces, quenching systems | Tensioning jacks, anchorage devices |

| Time Factor | Hours to complete dependent on metal and process | Immediate application during concrete casting |

| Cost Implications | Moderate operational costs due to energy use | Higher initial setup cost, lower long-term maintenance |

Introduction to Heat Treatment and Pre-tensioning

Heat treatment involves controlled heating and cooling processes to alter the microstructure and mechanical properties of materials, enhancing hardness, strength, and stress resistance. Pre-tensioning is a method used primarily in concrete construction where steel tendons are stretched before the concrete is cast, increasing the tensile strength of the finished structure. Both techniques improve material performance but target different stages and mechanisms in manufacturing and construction workflows.

Fundamental Concepts: Heat Treatment

Heat treatment involves controlled heating and cooling processes to alter the microstructure and mechanical properties of metals, enhancing strength, hardness, and ductility. It primarily affects atomic diffusion and phase transformations within the material, often involving processes such as annealing, quenching, and tempering. This fundamental concept contrasts with pre-tensioning, which mechanically induces stress to improve performance without altering the metal's intrinsic microstructure.

Core Principles: Pre-tensioning

Pre-tensioning involves applying tensile stress to steel strands or tendons before concrete casting, enhancing structural strength by inducing compressive forces within the concrete upon curing. This technique improves load-bearing capacity and crack resistance by ensuring that tensile stresses are counteracted, optimizing durability and performance in prestressed concrete elements. Unlike heat treatment, pre-tensioning focuses on mechanical stress manipulation rather than thermal alteration to achieve material enhancement.

Heat Treatment Processes in Industry

Heat treatment processes in industry involve controlled heating and cooling cycles designed to alter the microstructure of metals, improving properties such as hardness, strength, and ductility. Common heat treatment methods include annealing, quenching, and tempering, each tailored to achieve specific material characteristics essential for manufacturing and performance optimization. These processes enable precise control over mechanical properties, making them crucial for industries ranging from automotive to aerospace engineering.

Applications of Pre-tensioning Techniques

Pre-tensioning techniques are extensively applied in the construction of prestressed concrete beams, bridges, and slabs to enhance structural capacity and reduce material usage. These methods improve load-bearing performance by inducing internal stresses before external loads are applied, increasing durability and resistance to cracking. Industries such as civil engineering and infrastructure development rely on pre-tensioning for high-strength, long-span structures where precise control of tensile forces is critical.

Key Differences: Heat Treatment vs Pre-tensioning

Heat treatment involves heating and cooling metals to alter their microstructure, improving hardness, strength, and ductility, while pre-tensioning applies mechanical stress to steel tendons before concrete casting to enhance tensile strength. Heat treatment modifies material properties at the atomic level, whereas pre-tensioning induces residual stresses to resist service loads. The primary difference lies in heat treatment being a thermal process affecting material composition, and pre-tensioning being a mechanical process designed to improve structural performance.

Material Properties: Changes and Effects

Heat treatment alters material properties by modifying microstructure, enhancing hardness, strength, and ductility through processes like quenching and tempering. Pre-tensioning improves tensile strength and fatigue resistance by applying controlled stress to structural elements, inducing beneficial residual stresses that minimize deformation under loads. Both techniques optimize mechanical performance but target different property enhancements: heat treatment refines intrinsic material characteristics, while pre-tensioning adjusts stress distribution for improved durability.

Industry-Specific Use Cases

Heat treatment enhances material properties such as hardness and wear resistance in industries like aerospace and automotive, where components endure high stress and temperature variations. Pre-tensioning is critical in construction and civil engineering for improving the load-bearing capacity of concrete structures, ensuring long-term stability under heavy loads. Choosing between these methods depends on the desired mechanical performance and application environment, optimizing component durability and structural integrity.

Advantages and Limitations of Each Method

Heat treatment strengthens metals by altering their microstructure, enhancing hardness and wear resistance, but may cause dimensional distortion and residual stresses requiring post-treatment machining. Pre-tensioning improves structural component performance by inducing beneficial tensile stresses, reducing fatigue and stress corrosion cracking risks, yet demands precise control and specialized equipment, limiting its applicability to certain materials and geometries. Both methods optimize mechanical properties but must be selected based on component requirements, material behavior, and manufacturing constraints.

Choosing the Right Technique for Your Application

Heat treatment enhances material properties by altering microstructure through controlled heating and cooling cycles, ideal for improving hardness and wear resistance in metals. Pre-tensioning applies stress to components before service to improve load-bearing capacity and reduce deformation, commonly used in concrete and steel structures. Selecting the right technique depends on the application's performance requirements, material type, and desired mechanical characteristics, ensuring optimized durability and functionality.

Heat treatment Infographic

libterm.com

libterm.com