Dynamic friction occurs when two surfaces slide past each other, causing resistance proportional to the normal force and the materials involved. This type of friction plays a crucial role in everyday activities and mechanical systems by controlling motion and preventing slipping. Explore the rest of the article to understand how dynamic friction affects your daily life and engineering applications.

Table of Comparison

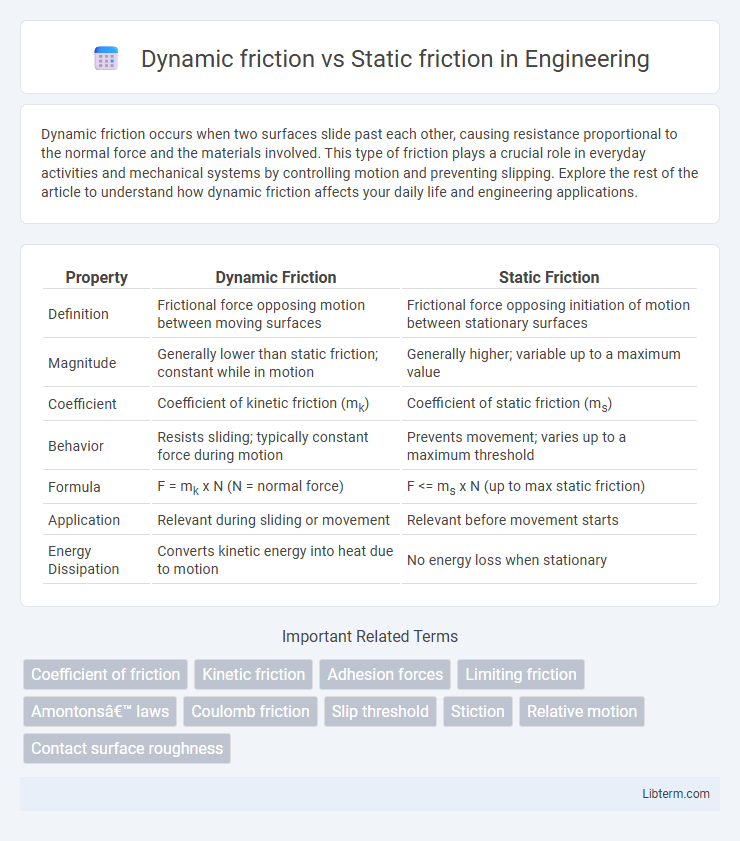

| Property | Dynamic Friction | Static Friction |

|---|---|---|

| Definition | Frictional force opposing motion between moving surfaces | Frictional force opposing initiation of motion between stationary surfaces |

| Magnitude | Generally lower than static friction; constant while in motion | Generally higher; variable up to a maximum value |

| Coefficient | Coefficient of kinetic friction (mk) | Coefficient of static friction (ms) |

| Behavior | Resists sliding; typically constant force during motion | Prevents movement; varies up to a maximum threshold |

| Formula | F = mk x N (N = normal force) | F <= ms x N (up to max static friction) |

| Application | Relevant during sliding or movement | Relevant before movement starts |

| Energy Dissipation | Converts kinetic energy into heat due to motion | No energy loss when stationary |

Understanding Friction: An Overview

Static friction prevents motion between two surfaces at rest by counteracting applied forces up to a maximum threshold, while dynamic friction acts during relative motion and is typically lower in magnitude. The coefficient of static friction is generally higher than that of dynamic friction, impacting energy consumption and wear in mechanical systems. Understanding these friction types is crucial in optimizing machine efficiency, designing braking systems, and enhancing material selection in engineering applications.

What Is Static Friction?

Static friction is the force that resists the initiation of motion between two surfaces in contact, preventing objects from sliding when at rest. It acts parallel to the surfaces and adjusts in magnitude up to a maximum value determined by the coefficient of static friction and the normal force. The maximum static friction force must be overcome by an external force to transition an object from rest to motion, after which dynamic friction takes over.

Defining Dynamic (Kinetic) Friction

Dynamic friction, also known as kinetic friction, refers to the resistive force acting between two surfaces in relative motion. This frictional force is generally lower than static friction, which is the force that must be overcome to initiate movement. The coefficient of kinetic friction quantifies this force and varies depending on surface materials and conditions.

Key Differences Between Static and Dynamic Friction

Static friction acts between surfaces at rest, preventing motion until a certain threshold force is exceeded, typically having a higher coefficient than dynamic friction. Dynamic friction comes into play once motion has started, offering less resistance and causing objects to slow down while sliding. The key difference lies in their magnitude and role: static friction resists the initiation of movement, whereas dynamic friction opposes ongoing motion.

Factors Affecting Static and Dynamic Friction

Static friction depends on the nature of the contact surfaces, surface roughness, and the normal force pressing them together, with adhesive forces at the microscopic level playing a crucial role. Dynamic friction is influenced by factors such as relative velocity between surfaces, surface texture, temperature, and the presence of lubricants that alter the interaction between moving surfaces. Differences in molecular bonding and surface deformation impact the magnitude of static friction typically being higher than dynamic friction under similar conditions.

Real-World Examples of Static vs Dynamic Friction

Static friction prevents movement when a stationary object, such as a parked car on an incline, resists sliding due to road surface grip. Dynamic friction occurs once the object starts moving, for example, when the car begins rolling downhill and the tires experience kinetic friction against the asphalt. Everyday instances like walking (static friction between shoes and ground) versus sliding on ice (dynamic friction) vividly illustrate the differences in frictional forces.

Measuring Friction Coefficients

Measuring friction coefficients involves determining the ratio of the frictional force to the normal force between two surfaces. Static friction coefficient is measured by gradually increasing the applied force until motion starts, identifying the maximum force that resists movement. Dynamic friction coefficient is measured once the object is in motion, often using a force sensor or tribometer to record the constant frictional force during sliding.

Importance of Friction in Engineering and Daily Life

Static friction prevents the initiation of motion between two surfaces, ensuring stability in structures and machinery, while dynamic friction acts during movement, controlling speed and wear. The precise understanding of both friction types is crucial for designing efficient brakes, tires, and mechanical components that rely on optimal grip and energy dissipation. Friction plays a vital role in everyday activities such as walking, driving, and handling objects, making it indispensable for safety and functionality in engineering and daily life.

Ways to Reduce or Increase Friction

To reduce dynamic friction, lubricants such as oils or greases create a smooth surface layer, minimizing contact between moving surfaces and lowering frictional resistance. Increasing static friction can be achieved by using rougher surface textures or materials with higher coefficients of friction, enhancing grip and preventing initial motion. Applying surface treatments like coatings or employing materials with specific tribological properties effectively controls friction levels in both static and dynamic states.

FAQs About Static and Dynamic Friction

Static friction prevents motion between two surfaces at rest by resisting initial movement, while dynamic friction acts during relative motion between sliding surfaces and usually has a lower coefficient. Common questions about static friction include how its magnitude adjusts up to a maximum to prevent motion, and why it is generally higher than dynamic friction. FAQ topics on dynamic friction often address its constant value during sliding and factors influencing its intensity, such as surface roughness and material properties.

Dynamic friction Infographic

libterm.com

libterm.com