Flow-induced noise occurs when fluid motion generates unwanted sound through turbulence, vibration, or pressure fluctuations in pipes, ducts, or around structures. Understanding the mechanisms behind this type of noise is crucial for improving acoustic comfort and optimizing the design of ventilation systems, aircraft, and automotive components. Discover how controlling flow-induced noise can enhance your environment by reading the rest of the article.

Table of Comparison

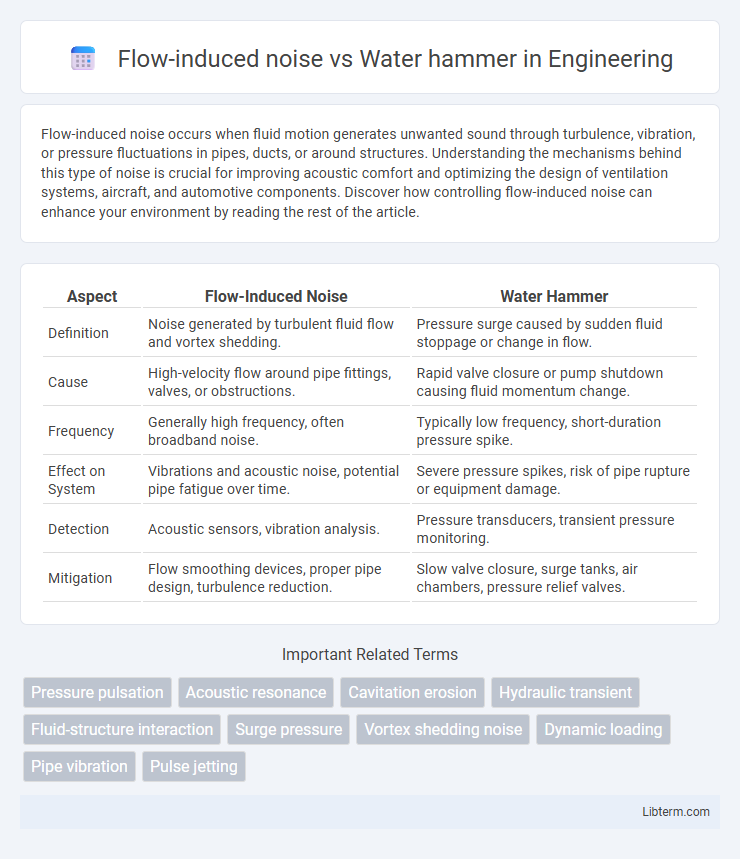

| Aspect | Flow-Induced Noise | Water Hammer |

|---|---|---|

| Definition | Noise generated by turbulent fluid flow and vortex shedding. | Pressure surge caused by sudden fluid stoppage or change in flow. |

| Cause | High-velocity flow around pipe fittings, valves, or obstructions. | Rapid valve closure or pump shutdown causing fluid momentum change. |

| Frequency | Generally high frequency, often broadband noise. | Typically low frequency, short-duration pressure spike. |

| Effect on System | Vibrations and acoustic noise, potential pipe fatigue over time. | Severe pressure spikes, risk of pipe rupture or equipment damage. |

| Detection | Acoustic sensors, vibration analysis. | Pressure transducers, transient pressure monitoring. |

| Mitigation | Flow smoothing devices, proper pipe design, turbulence reduction. | Slow valve closure, surge tanks, air chambers, pressure relief valves. |

Introduction to Flow-Induced Noise and Water Hammer

Flow-induced noise occurs when fluid motion interacts with pipe surfaces, causing vibrations and pressure fluctuations that generate acoustic emissions in pipelines. Water hammer is a specific transient phenomenon characterized by a sudden pressure surge resulting from rapid fluid velocity changes, such as valve closures or pump failures, producing intense shock waves within the piping system. Understanding these phenomena is crucial for designing piping infrastructure to minimize damage, noise pollution, and operational disruptions in fluid transport systems.

Understanding Flow-Induced Noise: Causes and Effects

Flow-induced noise originates from turbulent fluid movement and pressure fluctuations in pipelines, often caused by sudden changes in velocity or pipe geometry. This noise disrupts system performance and can lead to structural vibrations and material fatigue if unaddressed. Understanding these causes is crucial for designing efficient piping systems that minimize operational disturbances and prolong equipment lifespan.

What is Water Hammer? Definition and Mechanism

Water hammer is a pressure surge or wave caused when a fluid in motion is forced to stop or change direction suddenly within a pipeline. This phenomenon results from the momentum of the moving fluid, creating a high-pressure shockwave that can cause noise, vibration, and potential damage to pipes and equipment. Unlike flow-induced noise, which arises from turbulence and flow irregularities, water hammer specifically involves rapid changes in fluid velocity and pressure.

Key Differences Between Flow-Induced Noise and Water Hammer

Flow-induced noise arises from turbulent fluid motion and vortex shedding within pipelines, causing vibrations and audible sound that are generally continuous and of lower intensity. Water hammer results from sudden fluid momentum changes, such as rapid valve closures, creating high-pressure shock waves that produce sharp, transient pressure spikes and potential pipe damage. Key differences include the source mechanism, noise characteristics--continuous versus transient--and pressure impact, with water hammer posing a greater risk of structural harm.

Acoustic Impact: Comparing Flow-Induced Vibrations

Flow-induced noise arises from turbulent fluid motion causing pressure fluctuations and vibrations in piping systems, generating broad-band acoustic emissions. Water hammer produces high-intensity, impulsive pressure waves due to rapid valve closures or pump failures, resulting in sharp acoustic pulses and structural stress. Comparing flow-induced vibrations reveals that water hammer typically has a greater acoustic impact with sudden, high-amplitude noise events, whereas flow-induced noise presents continuous, lower-amplitude broadband sound affecting long-term system fatigue.

Common Sources in Industrial and Domestic Systems

Flow-induced noise and water hammer commonly originate from fluid dynamics disturbances in piping systems across industrial and domestic environments. Flow-induced noise typically arises from turbulent flow, valve vibrations, and pump operations, leading to continuous pressure fluctuations. Water hammer results from sudden changes in flow velocity caused by rapid valve closures or pump failures, generating high-pressure shock waves and potentially damaging pipelines.

Detection Methods for Flow-Induced Noise vs Water Hammer

Detection methods for flow-induced noise primarily involve acoustic sensors and vibration analysis to identify turbulent flow patterns and cavitation effects within pipelines. In contrast, water hammer detection relies on pressure transducers and high-speed data acquisition systems to capture sudden pressure surges and transient waves caused by rapid valve closures or pump failures. Advanced signal processing techniques, such as wavelet transforms and machine learning algorithms, enhance the accuracy of distinguishing flow-induced noise from water hammer events.

Prevention and Mitigation Strategies

Flow-induced noise can be prevented by optimizing pipe design parameters such as diameter, layout, and flow velocity to minimize turbulence and vortex shedding effects. Water hammer mitigation involves installing surge tanks, air chambers, or pressure relief valves to absorb sudden pressure changes caused by rapid valve closures or pump startups. Employing computational fluid dynamics (CFD) simulations helps identify critical points for both phenomena, enabling targeted interventions that reduce noise and pressure surges efficiently.

Consequences of Ignoring Pipeline Noise Issues

Ignoring flow-induced noise and water hammer in pipelines can lead to significant structural damage, including pipe fatigue, joint failures, and eventual leaks. Persistent noise vibrations may cause premature wear of valves, pumps, and fittings, increasing maintenance costs and downtime. Failure to address these issues also risks operational disruptions and potential safety hazards due to sudden pressure surges and pipe bursts.

Best Practices for Pipeline Design and Maintenance

Flow-induced noise in pipelines results from turbulent fluid dynamics and improper pipe support, while water hammer occurs due to sudden pressure surges caused by rapid valve closures or pump failures. Best practices for pipeline design and maintenance include installing adequate surge protection devices, using gradual valve actuation, ensuring proper pipe anchoring and alignment, and routinely inspecting for corrosion or blockages to mitigate both noise and pressure transients. Employing computational fluid dynamics (CFD) simulations during design helps predict flow behavior and optimize pipe diameters and layouts to minimize these issues.

Flow-induced noise Infographic

libterm.com

libterm.com