Thermal analysis involves studying the response of materials to changes in temperature, revealing critical properties such as melting points, crystallization, and thermal stability. This method is essential for improving product performance, safety, and quality across various industries including pharmaceuticals, polymers, and metallurgy. Explore the following article to understand how thermal analysis can optimize your material applications and innovation.

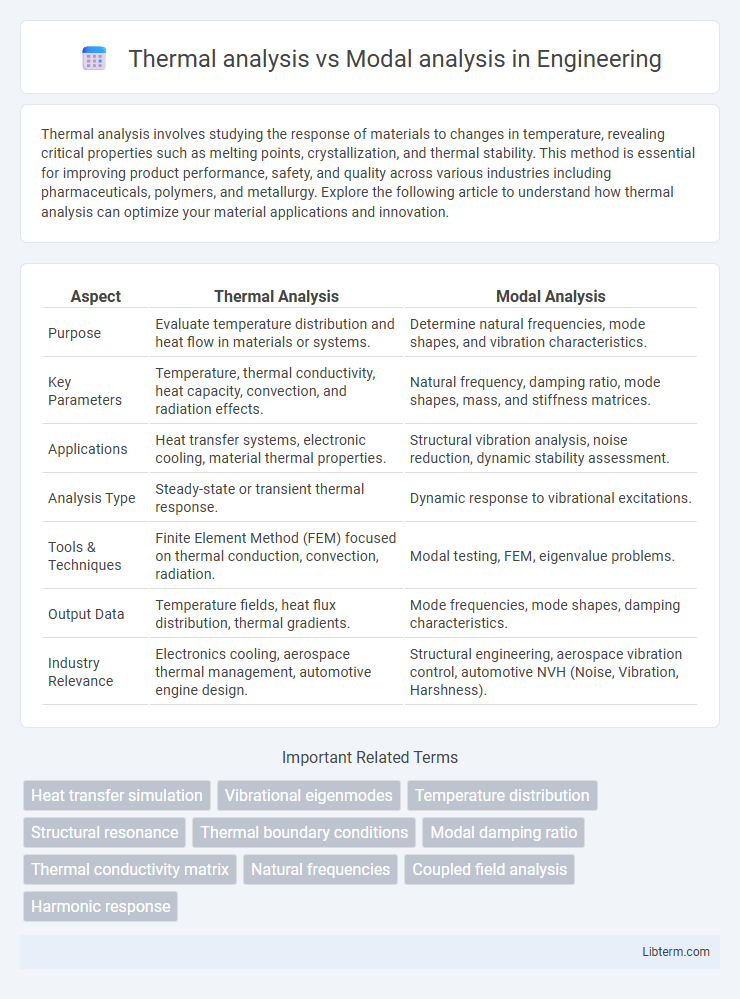

Table of Comparison

| Aspect | Thermal Analysis | Modal Analysis |

|---|---|---|

| Purpose | Evaluate temperature distribution and heat flow in materials or systems. | Determine natural frequencies, mode shapes, and vibration characteristics. |

| Key Parameters | Temperature, thermal conductivity, heat capacity, convection, and radiation effects. | Natural frequency, damping ratio, mode shapes, mass, and stiffness matrices. |

| Applications | Heat transfer systems, electronic cooling, material thermal properties. | Structural vibration analysis, noise reduction, dynamic stability assessment. |

| Analysis Type | Steady-state or transient thermal response. | Dynamic response to vibrational excitations. |

| Tools & Techniques | Finite Element Method (FEM) focused on thermal conduction, convection, radiation. | Modal testing, FEM, eigenvalue problems. |

| Output Data | Temperature fields, heat flux distribution, thermal gradients. | Mode frequencies, mode shapes, damping characteristics. |

| Industry Relevance | Electronics cooling, aerospace thermal management, automotive engine design. | Structural engineering, aerospace vibration control, automotive NVH (Noise, Vibration, Harshness). |

Introduction to Thermal Analysis and Modal Analysis

Thermal analysis evaluates material properties and system behavior under temperature changes, focusing on heat transfer, thermal expansion, and temperature distribution. Modal analysis investigates the dynamic characteristics of structures by identifying natural frequencies, mode shapes, and damping ratios crucial for vibration and stability assessments. Both methods are essential in engineering design to ensure performance reliability under thermal stresses and dynamic loading conditions.

Fundamental Concepts of Thermal Analysis

Thermal analysis involves studying material properties as they change with temperature, focusing on heat flow, thermal expansion, and phase transitions to understand material behavior under thermal stress. It examines conduction, convection, and radiation phenomena to predict temperature distribution and thermal gradients within components. Modal analysis, by contrast, investigates structural vibrations and natural frequencies without directly addressing heat-related effects, emphasizing dynamic response rather than thermal properties.

Key Principles of Modal Analysis

Modal analysis examines the dynamic characteristics of structures by identifying natural frequencies, mode shapes, and damping ratios, which are critical for predicting vibration behavior and structural integrity. Unlike thermal analysis that studies heat distribution and temperature effects, modal analysis relies on solving eigenvalue problems to uncover resonance phenomena and dynamic response under various loading conditions. Accurate modal parameters enable engineers to design safer, quieter, and more efficient mechanical systems by mitigating resonant vibrations and enhancing fatigue life.

Differences in Objectives and Applications

Thermal analysis evaluates temperature distribution, heat flow, and thermal properties in materials or systems, primarily to predict performance under varying thermal conditions and prevent overheating or thermal failure in applications like electronics cooling and material processing. Modal analysis focuses on determining natural frequencies, mode shapes, and dynamic response of structures to predict vibration characteristics, crucial for ensuring structural integrity and avoiding resonance in mechanical components, automotive parts, and aerospace structures. The key difference lies in thermal analysis addressing thermal behavior and heat transfer, while modal analysis examines dynamic mechanical behavior and vibrational modes.

Essential Tools and Software Used

Thermal analysis primarily utilizes software such as ANSYS Mechanical, COMSOL Multiphysics, and SolidWorks Simulation to evaluate temperature distribution, heat transfer, and thermal stresses in materials and components. Modal analysis relies on tools like MSC Nastran, ABAQUS, and Siemens NX to assess vibration modes, natural frequencies, and dynamic response of mechanical structures. Both analyses require finite element method (FEM) based software to accurately model complex physical phenomena and ensure structural integrity under varying conditions.

Input Parameters for Each Analysis Type

Thermal analysis input parameters primarily include temperature distribution, heat flux, convection coefficients, material thermal properties, and boundary conditions related to heat sources and sinks. Modal analysis requires inputs such as mass distribution, stiffness properties, boundary supports, and damping factors to determine natural frequencies and mode shapes. Accurate definition of these parameters is crucial for reliable simulation results in both thermal and modal analyses.

Data Interpretation and Result Comparison

Thermal analysis evaluates temperature distribution and heat flow in materials, providing data on thermal gradients, heat capacity, and thermal conductivity, essential for assessing thermal stresses and deformation. Modal analysis identifies natural frequencies, mode shapes, and damping ratios of structures, crucial for understanding dynamic behavior and vibration characteristics under operational loads. Comparing results, thermal analysis highlights thermal-induced material changes, while modal analysis focuses on dynamic response, enabling comprehensive design optimization by integrating thermal effects with structural vibration performance.

Industries and Scenarios of Application

Thermal analysis is critical in industries like electronics, automotive, and aerospace for evaluating heat distribution, preventing overheating, and optimizing material performance under varying temperature conditions. Modal analysis finds extensive use in civil engineering, automotive, and machinery manufacturing to assess vibration characteristics, structural integrity, and resonance frequencies in components subjected to dynamic loading. Both analyses support design validation and failure prevention but target different physical phenomena essential to specific industrial applications.

Challenges and Limitations

Thermal analysis faces challenges in accurately modeling transient heat transfer and material property variations at different temperatures, limiting its precision in dynamic environments. Modal analysis struggles with capturing complex boundary conditions and non-linearities in real-world structures, which can lead to inaccuracies in natural frequency and mode shape predictions. Both analyses require high computational resources for fine-mesh simulations, often constraining their application in large-scale or real-time engineering problems.

Summary: Choosing Between Thermal and Modal Analysis

Thermal analysis evaluates temperature distribution and heat transfer effects in materials and systems, crucial for ensuring reliable thermal management. Modal analysis examines natural frequencies and vibration modes to predict structural response under dynamic loading and avoid resonant failures. Selecting between thermal and modal analysis depends on the primary concern: thermal effects and heat dissipation require thermal analysis, while dynamic behavior and vibration characteristics mandate modal analysis.

Thermal analysis Infographic

libterm.com

libterm.com