Creep refers to the slow, permanent deformation of materials under constant stress, commonly observed in metals, polymers, and concrete at high temperatures. Understanding creep behavior is crucial for predicting the lifespan and ensuring the safety of structures such as bridges, aircraft, and turbines. Discover how creep impacts your engineering projects and learn the key factors influencing material performance in the full article.

Table of Comparison

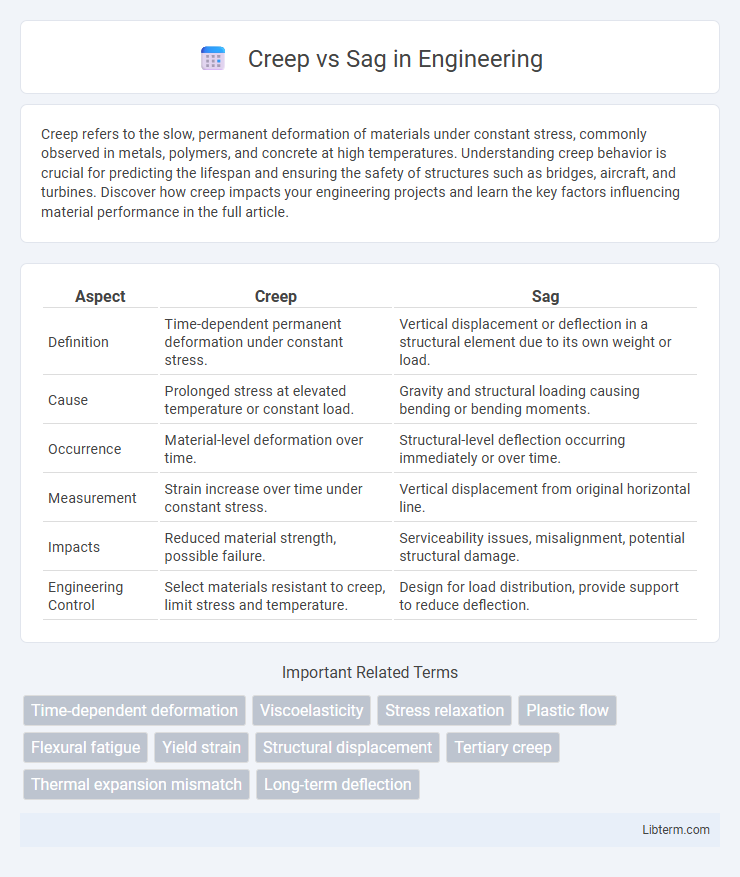

| Aspect | Creep | Sag |

|---|---|---|

| Definition | Time-dependent permanent deformation under constant stress. | Vertical displacement or deflection in a structural element due to its own weight or load. |

| Cause | Prolonged stress at elevated temperature or constant load. | Gravity and structural loading causing bending or bending moments. |

| Occurrence | Material-level deformation over time. | Structural-level deflection occurring immediately or over time. |

| Measurement | Strain increase over time under constant stress. | Vertical displacement from original horizontal line. |

| Impacts | Reduced material strength, possible failure. | Serviceability issues, misalignment, potential structural damage. |

| Engineering Control | Select materials resistant to creep, limit stress and temperature. | Design for load distribution, provide support to reduce deflection. |

Introduction to Creep and Sag

Creep refers to the gradual, time-dependent deformation of materials under constant stress, commonly observed in metals, plastics, and concrete at elevated temperatures. Sag is the vertical deflection or downward bending of structural elements, such as beams or cables, resulting from sustained loads or creep effects. Understanding creep behavior is essential to predict sag magnitude and ensure long-term structural integrity in engineering applications.

Definition of Creep

Creep refers to the gradual, time-dependent deformation of a material under sustained stress, often observed in metals, polymers, and concrete at elevated temperatures or constant loads. Unlike sag, which describes the visible downward deflection or bending of a structural element due to weight or load, creep specifically involves microscopic structural changes leading to permanent strain. Understanding creep behavior is critical for predicting the long-term durability and mechanical stability of components in aerospace, civil engineering, and manufacturing applications.

Definition of Sag

Sag is the vertical deformation or displacement of a material or structure under a sustained load over time, primarily due to its inherent viscoelastic or plastic properties. Unlike creep, which describes the time-dependent strain accumulation in materials subjected to constant stress, sag specifically refers to the measurable downward deflection or bending observed in beams, cables, or other structural elements. Sag quantification is critical in engineering design to ensure structural integrity and serviceability under long-term loading conditions.

Key Differences Between Creep and Sag

Creep refers to the slow, permanent deformation of a material under continuous stress over time, while sag describes the downward bending or deflection of a structure due to its own weight or applied loads. The primary difference lies in time scale and reversibility: creep occurs gradually and can lead to irreversible changes, whereas sag is often an immediate response that may be partially or fully recoverable once the load is removed. Understanding these distinctions is critical in material science and structural engineering to ensure long-term integrity and performance of components such as beams, cables, and metal alloys.

Causes of Creep

Creep occurs due to prolonged exposure to constant stress, especially at elevated temperatures or under sustained mechanical loads, causing materials to deform slowly over time. Microstructural changes such as dislocation movement, grain boundary sliding, and diffusion contribute significantly to creep in metals and polymers. Factors like high temperature, applied stress, and material properties accelerate the creep process, distinguishing it from sag, which is primarily a gravitational deflection issue.

Causes of Sag

Sag in materials primarily results from sustained loads causing gradual deformation due to insufficient elastic recovery, often exacerbated by factors such as elevated temperatures, material composition, and long-term stress exposure. Unlike immediate deformation under load, sag develops over time as the internal structure of materials rearranges, which can be accelerated by environmental conditions like humidity or chemical exposure. Factors such as non-uniform load distribution and suboptimal support structures also contribute to the progressive sagging observed in beams, cables, and other structural elements.

Effects of Creep and Sag on Materials

Creep causes permanent deformation in materials subjected to prolonged stress at high temperatures, leading to gradual elongation and potential structural failure over time. Sag results from material deflection due to its own weight or applied loads, causing bending and reduced load-bearing capacity. Both creep and sag compromise mechanical integrity by altering shape and stress distribution, accelerating wear and potential fracture in components.

Creep vs Sag: Real-World Examples

Creep refers to the slow, permanent deformation of a material under constant stress, commonly observed in metal components operating at high temperatures, such as turbine blades in jet engines. Sag is the downward deflection or bending of a structural element under its own weight or applied load, frequently seen in overhead power lines and bridge beams. Real-world cases include the gradual sagging of railway tracks causing alignment issues and creep deformation in turbine blades leading to reduced engine efficiency and potential failure.

Prevention and Control Methods

Effective prevention and control of creep and sag in structural materials involve selecting high-quality alloys with high creep resistance and implementing rigorous design standards that account for operating temperatures and stress levels. Regular inspection and maintenance programs using non-destructive testing techniques help detect early signs of deformation, enabling timely interventions such as stress relief treatments or component replacements. Employing advanced cooling systems and optimizing load distribution further minimizes the risk of creep and sag, enhancing the longevity and safety of engineering structures.

Conclusion: Creep vs Sag Comparison

Creep refers to the permanent deformation of materials under constant stress over time, while sag specifically describes the downward deflection or bending in structural components due to their own weight or applied loads. Both phenomena affect structural integrity, but creep is a time-dependent molecular change, whereas sag is a visible geometric displacement. Understanding material properties and loading conditions is essential for mitigating both creep and sag in engineering designs.

Creep Infographic

libterm.com

libterm.com