Metric thread is a standardized screw thread used globally for fasteners, characterized by its symmetrical V-shaped profile with a 60-degree angle. It ensures compatibility and precision in mechanical assemblies by following International System units for thread pitch and diameter. Explore the article to understand how metric threads enhance your engineering projects and where they are applied.

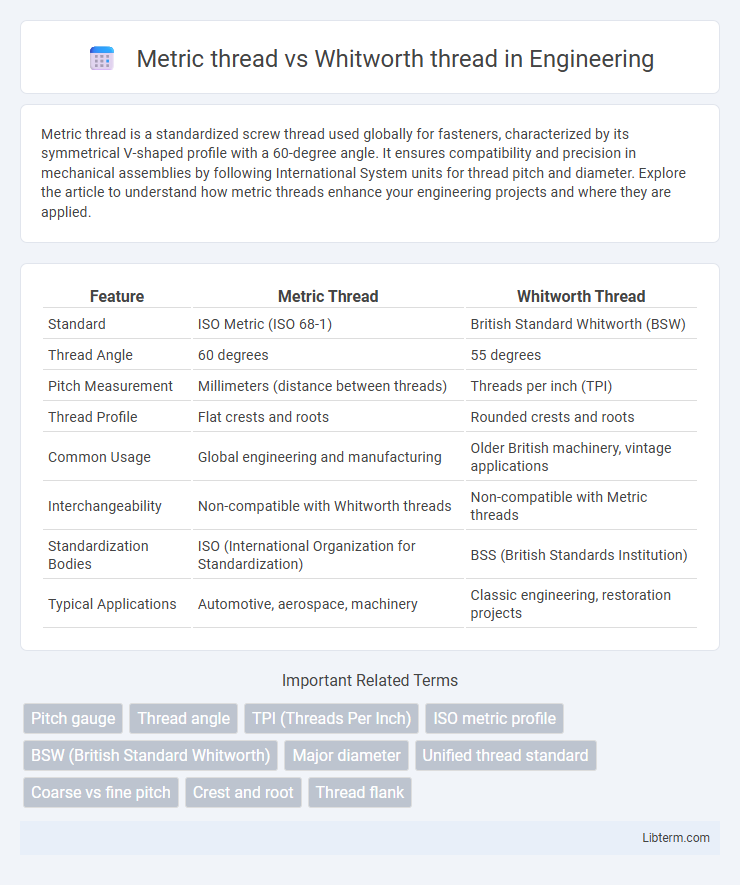

Table of Comparison

| Feature | Metric Thread | Whitworth Thread |

|---|---|---|

| Standard | ISO Metric (ISO 68-1) | British Standard Whitworth (BSW) |

| Thread Angle | 60 degrees | 55 degrees |

| Pitch Measurement | Millimeters (distance between threads) | Threads per inch (TPI) |

| Thread Profile | Flat crests and roots | Rounded crests and roots |

| Common Usage | Global engineering and manufacturing | Older British machinery, vintage applications |

| Interchangeability | Non-compatible with Whitworth threads | Non-compatible with Metric threads |

| Standardization Bodies | ISO (International Organization for Standardization) | BSS (British Standards Institution) |

| Typical Applications | Automotive, aerospace, machinery | Classic engineering, restoration projects |

Introduction to Thread Standards

Metric thread standards, defined by ISO, use a pitch measured in millimeters and are widely adopted internationally for precise engineering applications. Whitworth thread standards, developed in the 19th century, feature an imperial measurement system with a 55-degree thread angle, commonly used in British and Commonwealth countries. Understanding the distinction between these thread types is crucial for compatibility in mechanical design and manufacturing processes.

Overview of Metric Threads

Metric threads are standardized screw threads characterized by their profile, pitch, and diameter measured in millimeters, offering precise dimensional consistency for global engineering applications. They feature a 60-degree thread angle and flat crests and roots, enhancing strength and compatibility across international machinery and fasteners. Metric thread systems simplify manufacturing and replacement due to widespread adoption and uniform specifications outlined in ISO standards.

Overview of Whitworth Threads

Whitworth threads, developed by Sir Joseph Whitworth in 1841, utilize a 55-degree thread angle with rounded crests and roots, providing improved strength and reduced stress concentration compared to sharp threads. These threads are primarily standardized under the British Standard Whitworth (BSW) and British Standard Fine (BSF) specifications, commonly used in British and Commonwealth engineering applications. Whitworth threads feature coarse pitches and are essential for legacy machinery, ensuring compatibility and reliable fastening in historical and industrial contexts.

Historical Development of Thread Types

Metric threads, standardized by the International Organization for Standardization (ISO) in 1947, emerged from a need for global uniformity in manufacturing during the 20th century. Whitworth threads, devised by Joseph Whitworth in 1841, represent the first standardized thread form and dominated British engineering and imperial systems for over a century. The transition from Whitworth to metric threads reflects industrial globalization and the shift towards a simplified, universally compatible thread system.

Key Differences in Thread Geometry

Metric threads feature a 60-degree thread angle with flat crests and roots, promoting efficient load distribution and compatibility with international standards. Whitworth threads have a 55-degree thread angle with rounded crests and roots, which enhances fatigue resistance in applications involving cyclic stress. The pitch and depth also differ, with metric threads typically having finer pitches and shallower depths compared to the coarser, deeper Whitworth threads designed for robust fastening.

Applications of Metric Threads

Metric threads are widely used in automotive, aerospace, and machinery industries due to their standardized pitch and diameter, ensuring compatibility and interchangeability across international markets. Their precise manufacturing enables high-strength fastening in mechanical assemblies and equipment that require reliable torque and load distribution. Metric threads dominate applications involving modern engineering components, where uniformity and global standards facilitate mass production and maintenance.

Applications of Whitworth Threads

Whitworth threads are widely used in British engineering, automotive, and railway industries due to their coarse pitch, which provides strong mechanical grip and resistance to vibration loosening. Their standardized 55-degree thread angle suits heavy-duty fasteners in structural applications and vintage machinery restoration. Whitworth threads are often preferred for legacy equipment maintenance and applications requiring robust corrosion resistance and high torque tolerance.

Interchangeability and Compatibility Issues

Metric threads and Whitworth threads differ primarily in their thread angle and pitch, making them generally incompatible and not interchangeable without adapters. Metric threads have a 60-degree thread angle, while Whitworth threads use a 55-degree angle, causing poor fit and potential mechanical failure if mismatched. Using metric bolts in Whitworth nuts or vice versa can lead to stripped threads and compromised joint integrity, highlighting the importance of selecting the correct standard for compatibility.

Advantages and Disadvantages of Each Thread

Metric threads offer standardized pitch and diameter sizes, ensuring compatibility across international applications and simplifying manufacturing with precise tolerances; however, they may lack robustness in older equipment designed for Imperial standards. Whitworth threads provide superior strength and durability due to their rounded thread profile, reducing stress concentration and fatigue in heavy-duty applications, but their coarse pitch limits fine adjustment and is less common globally. Metric threads excel in precision and widespread use, while Whitworth threads are favored for their mechanical strength and historical relevance in British engineering.

Choosing the Right Thread for Your Project

Selecting the right thread for your project depends on compatibility and application requirements. Metric threads, standardized by ISO, offer precise dimensions and are globally widespread, making them ideal for modern machinery and international parts. Whitworth threads, with their distinctive 55-degree angle and rounded profile, excel in British-made equipment and vintage restorations where original specifications are crucial.

Metric thread Infographic

libterm.com

libterm.com