Setting shapes the mood and context of a story by establishing the time, place, and environment where events unfold. It influences characters' behaviors and plot development, making it a crucial element in storytelling. Discover how mastering setting can transform your narrative by reading the rest of this article.

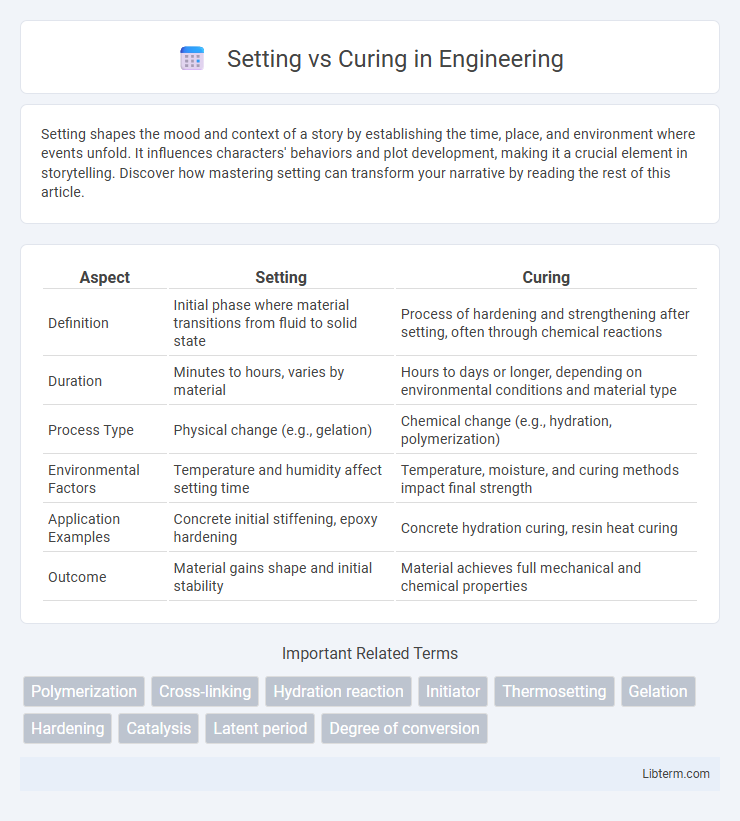

Table of Comparison

| Aspect | Setting | Curing |

|---|---|---|

| Definition | Initial phase where material transitions from fluid to solid state | Process of hardening and strengthening after setting, often through chemical reactions |

| Duration | Minutes to hours, varies by material | Hours to days or longer, depending on environmental conditions and material type |

| Process Type | Physical change (e.g., gelation) | Chemical change (e.g., hydration, polymerization) |

| Environmental Factors | Temperature and humidity affect setting time | Temperature, moisture, and curing methods impact final strength |

| Application Examples | Concrete initial stiffening, epoxy hardening | Concrete hydration curing, resin heat curing |

| Outcome | Material gains shape and initial stability | Material achieves full mechanical and chemical properties |

Understanding Setting and Curing: Key Definitions

Setting refers to the initial phase where a material transitions from a fluid or plastic state to a solid form, defining its shape and structural integrity. Curing involves the ongoing chemical or physical processes that strengthen the material over time, enhancing properties such as hardness, durability, and resistance. Understanding setting and curing is essential for optimizing performance in construction, adhesives, and composites by controlling timing, environmental conditions, and material formulations.

The Science Behind Setting vs Curing

Setting and curing are two distinct chemical processes crucial in materials science, especially in cement and adhesives. Setting refers to the initial hardening phase where a material transitions from a fluid or plastic state to a solid state through physical changes, while curing involves the chemical reactions, such as hydration in cement or polymerization in resins, that enhance strength and durability over time. Understanding the molecular mechanisms behind setting and curing allows optimization of material properties, ensuring proper bonding, structural integrity, and longevity in construction and manufacturing applications.

Material Types: When Setting or Curing Matters

Setting refers to the initial phase where a material transitions from a liquid or plastic state to a solid state, crucial for materials like cement and plaster. Curing involves chemical reactions that continue to strengthen and stabilize materials such as concrete, adhesives, and coatings over time. Understanding the specific requirements of materials like epoxy resins, concrete, and silicones ensures optimal performance by distinguishing when setting is sufficient or when extended curing is necessary.

Chemical and Physical Processes Involved

Setting involves the initial phase where a material undergoes a chemical reaction, such as hydration in cement, leading to the formation of rigid microstructures. Curing is the subsequent process that maintains optimal moisture and temperature conditions, facilitating further chemical reactions that enhance strength and durability. Both processes are critical, with setting primarily driven by rapid physical hardening and curing ensuring long-term chemical stabilization and integrity.

Factors Affecting Setting and Curing Times

Temperature and humidity significantly influence setting and curing times, with higher temperatures generally accelerating chemical reactions in materials like concrete and adhesives. The composition of the material, including the type and amount of binder, water content, and additives, also determines the duration of setting and curing processes. Environmental conditions such as airflow and substrate porosity impact moisture evaporation rates, further affecting the speed at which materials harden and reach their full strength.

Common Mistakes: Mixing Up Setting and Curing

Confusing setting and curing often leads to improper drying times, as setting refers to the initial hardening phase while curing involves the ongoing chemical reactions that strengthen the material. A common mistake is assuming that once a surface feels dry (set), the material has fully cured, resulting in premature handling or use that compromises durability. Accurate distinction and adherence to manufacturer guidelines for both setting and curing phases ensure optimal performance and longevity of coatings, adhesives, or concrete.

Practical Applications in Construction and Manufacturing

Setting refers to the initial hardening phase of materials like concrete or adhesives, where the mixture transitions from liquid to solid state, enabling early handling and shaping in construction and manufacturing processes. Curing involves maintaining optimal moisture, temperature, and time conditions post-setting to enhance the material's strength and durability, which is critical for structural integrity and long-term performance. Effective control of setting and curing parameters directly impacts project timelines, product quality, and safety standards in industries such as building construction, manufacturing of composites, and infrastructure development.

Testing Methods for Setting and Curing

Testing methods for setting and curing concrete crucially influence structural integrity and performance. Setting time is commonly evaluated using the Vicat needle test, which measures the penetration resistance of cement paste to determine initial and final set, while curing effectiveness is assessed through compressive strength tests and ultrasonic pulse velocity to monitor hydration progress and detect internal defects. Advanced techniques such as maturity meters and calorimetry also provide accurate data on temperature and chemical reactions during curing, optimizing timing for formwork removal and load application.

Best Practices for Optimal Results

Setting involves the initial hardening phase of materials like concrete or adhesives, whereas curing ensures the material achieves full strength and durability through controlled moisture and temperature conditions. Best practices for optimal results include maintaining proper temperature ranges (typically between 50-75degF for concrete), continual moisture retention through methods like wet curing or sealing, and avoiding premature loading or disturbance during both setting and curing phases. Employing precise timing and environmental controls maximizes bond strength, longevity, and performance in construction and manufacturing applications.

Innovations in Setting and Curing Technologies

Innovations in setting and curing technologies have revolutionized construction and manufacturing by introducing advanced materials like rapid-setting concrete and UV-curable resins. These technologies optimize the chemical reactions involved, significantly reducing time and enhancing durability while enabling precise control through automated systems and sensors. Integration of nanotechnology and smart curing methods further enhances performance, resulting in stronger structures and more efficient production processes.

Setting Infographic

libterm.com

libterm.com