Differential Scanning Calorimeter (DSC) measures heat flow associated with material transitions, providing precise thermal analysis for polymers, pharmaceuticals, and metals. It helps determine melting points, crystallization, and glass transition temperatures crucial for quality control and research. Explore this article to understand how DSC can enhance your material characterization and product development.

Table of Comparison

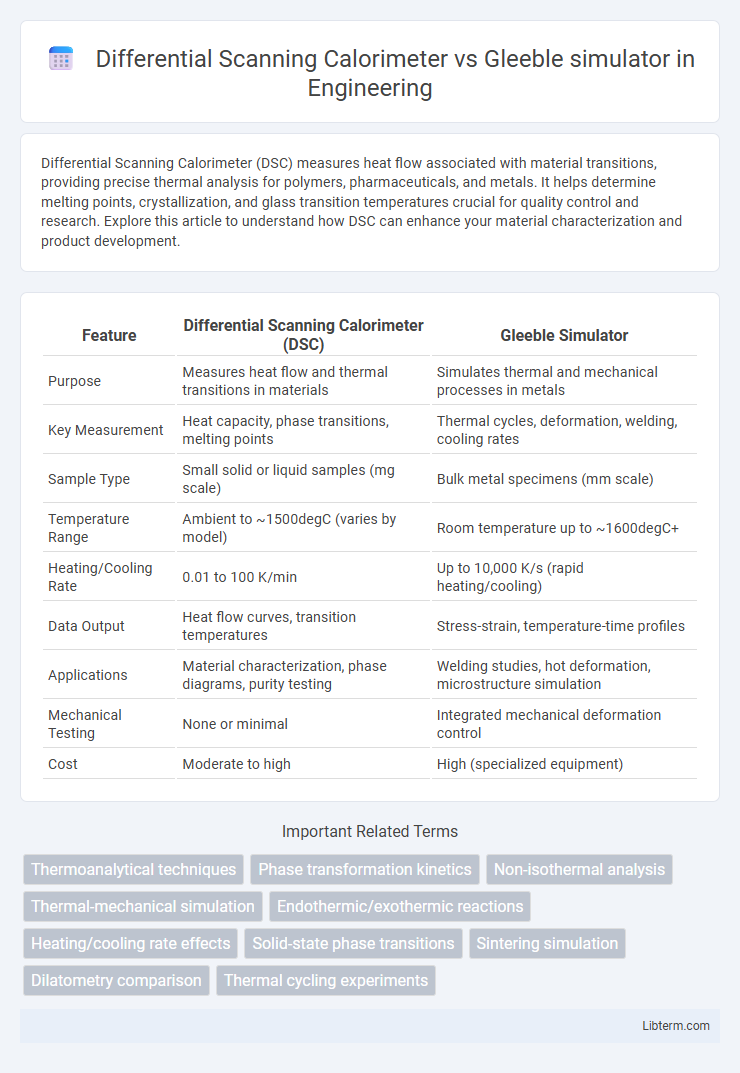

| Feature | Differential Scanning Calorimeter (DSC) | Gleeble Simulator |

|---|---|---|

| Purpose | Measures heat flow and thermal transitions in materials | Simulates thermal and mechanical processes in metals |

| Key Measurement | Heat capacity, phase transitions, melting points | Thermal cycles, deformation, welding, cooling rates |

| Sample Type | Small solid or liquid samples (mg scale) | Bulk metal specimens (mm scale) |

| Temperature Range | Ambient to ~1500degC (varies by model) | Room temperature up to ~1600degC+ |

| Heating/Cooling Rate | 0.01 to 100 K/min | Up to 10,000 K/s (rapid heating/cooling) |

| Data Output | Heat flow curves, transition temperatures | Stress-strain, temperature-time profiles |

| Applications | Material characterization, phase diagrams, purity testing | Welding studies, hot deformation, microstructure simulation |

| Mechanical Testing | None or minimal | Integrated mechanical deformation control |

| Cost | Moderate to high | High (specialized equipment) |

Introduction to Thermal Analysis Techniques

Differential Scanning Calorimeter (DSC) measures heat flow associated with phase transitions, offering precise data on melting points, crystallization, and specific heat capacity. The Gleeble simulator replicates real-time thermal-mechanical processes, enabling simulation of welding, forming, and heat treatment conditions on material samples. Both techniques provide critical insight into thermal properties but differ in application scope, with DSC emphasizing calorimetric analysis and Gleeble focusing on coupled thermal and mechanical behavior.

What is a Differential Scanning Calorimeter (DSC)?

A Differential Scanning Calorimeter (DSC) is an analytical instrument used to measure the heat flow associated with phase transitions and chemical reactions in materials as a function of temperature and time. It provides precise data on melting points, crystallization, glass transition temperatures, and specific heat capacity, essential for characterizing polymers, metals, and pharmaceuticals. Unlike the Gleeble simulator, which replicates thermo-mechanical processing conditions such as welding or hot rolling, the DSC focuses on thermal analysis without mechanical deformation.

Understanding the Gleeble Simulator

The Gleeble simulator enables precise control of temperature, strain, and strain-rate, replicating real-world thermal-mechanical processes to study material behavior under dynamic conditions. Unlike the Differential Scanning Calorimeter (DSC), which primarily measures heat flow and phase transitions during controlled heating or cooling, the Gleeble system integrates mechanical deformation with rapid heating and cooling cycles. This capability makes the Gleeble simulator essential for investigating weldability, hot deformation, and thermomechanical treatments in metals and alloys.

Key Principles: How DSC and Gleeble Simulate Thermal Events

Differential Scanning Calorimeters (DSC) measure heat flow associated with phase transitions or chemical reactions by precisely controlling sample temperature and recording endothermic or exothermic events. Gleeble simulators replicate real-world thermal-mechanical conditions by applying rapid heating, cooling, and mechanical deformation to metals to study microstructural evolution under controlled thermal cycles. While DSC focuses on calorimetric analysis of thermal events, Gleeble integrates thermal and mechanical simulations to mimic industrial processing conditions and characterize material behavior.

Measurement Capabilities: Heat Flow vs. Mechanical Simulation

Differential Scanning Calorimeters (DSCs) precisely measure heat flow associated with phase transitions, chemical reactions, and thermal properties by tracking energy changes in a sample as it is heated or cooled. In contrast, Gleeble simulators replicate mechanical processes such as deformation, welding, and thermal cycles by applying controlled thermal and mechanical loads to material samples, providing insight into stress-strain behavior and microstructural evolution. DSCs excel in quantifying thermal properties and phase transformations, while Gleeble systems are essential for studying thermo-mechanical responses and manufacturing simulations under real-world conditions.

Applications in Material Science: DSC vs Gleeble

Differential Scanning Calorimeter (DSC) is widely used to analyze phase transitions, melting points, and heat capacities of materials, enabling detailed thermal property characterization in polymers, metals, and ceramics. Gleeble simulators excel in replicating real-time thermo-mechanical processes such as welding, forging, and heat treatment by simulating high strain rates and dynamic thermal cycles, offering insights into microstructural evolution and mechanical behavior. Combining DSC's precise thermal analysis with Gleeble's deformation simulation provides comprehensive understanding crucial for advanced material design and performance optimization.

Sample Preparation and Testing Procedures

Differential Scanning Calorimeter (DSC) requires precise sample preparation involving small, encapsulated specimens weighing typically 5-20 mg to ensure uniform heating and accurate thermal analysis. The Gleeble simulator involves larger, bulkier samples often machined into specific shapes to endure mechanical testing under thermal cycles, allowing real-time control of temperature and deformation. DSC testing is conducted by heating or cooling samples at controlled rates within a sealed environment, while Gleeble testing integrates mechanical loading with rapid heating and cooling, enabling simulation of complex thermomechanical processes.

Accuracy, Sensitivity, and Data Output Comparison

Differential Scanning Calorimeters (DSCs) provide high sensitivity and precise heat flow measurements, making them ideal for detailed thermal transitions with accurate temperature control. Gleeble simulators offer exceptional accuracy in simulating real-world thermomechanical processes by combining controlled heating, cooling, and mechanical deformation, enabling comprehensive data on material behavior under stress. While DSCs excel in detailed heat capacity and phase change data output, Gleeble systems deliver multifaceted output including stress-strain response, microstructural evolution, and thermal profiles, crucial for advanced materials research.

Advantages and Limitations of Each Technique

Differential Scanning Calorimeter (DSC) offers precise measurement of thermal transitions such as melting points and phase changes, providing quantitative heat flow data useful for material characterization, though it is limited by small sample size and inability to replicate complex mechanical stresses. The Gleeble simulator excels in reproducing real-world thermomechanical conditions, enabling the study of microstructural evolution under simultaneous thermal and mechanical loads, but it requires complex setup and higher costs that constrain routine testing. Both techniques complement each other in materials research, with DSC ideal for baseline thermal analysis and Gleeble suited for simulating manufacturing processes like welding or forging.

Choosing the Right Tool for Your Research: DSC or Gleeble?

Differential Scanning Calorimeters (DSC) provide precise thermal analysis by measuring heat flow associated with phase transitions and chemical reactions, ideal for studying thermal properties in polymers, pharmaceuticals, and metals. Gleeble simulators offer dynamic mechanical testing under controlled temperature and strain rates, enabling simulation of real-world thermal-mechanical processes in metals during welding or forming. Selecting DSC or Gleeble depends on whether your research emphasizes thorough thermal property characterization or combined thermal-mechanical behavior under deformation conditions.

Differential Scanning Calorimeter Infographic

libterm.com

libterm.com