Plug flow describes fluid movement where all particles travel at the same velocity, resulting in a uniform flow profile without mixing across streamlines. Laminar flow, in contrast, features smooth, orderly layers of fluid sliding past one another with varying velocities, minimizing turbulence and maintaining a predictable flow pattern. Explore the rest of this article to understand how these flow types impact your fluid dynamics applications.

Table of Comparison

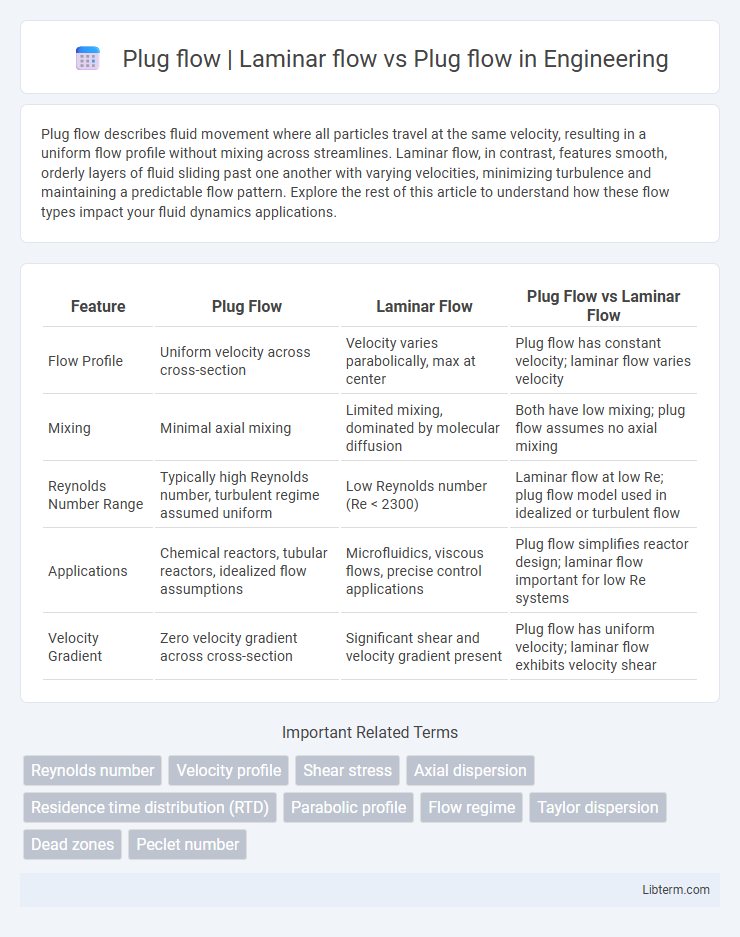

| Feature | Plug Flow | Laminar Flow | Plug Flow vs Laminar Flow |

|---|---|---|---|

| Flow Profile | Uniform velocity across cross-section | Velocity varies parabolically, max at center | Plug flow has constant velocity; laminar flow varies velocity |

| Mixing | Minimal axial mixing | Limited mixing, dominated by molecular diffusion | Both have low mixing; plug flow assumes no axial mixing |

| Reynolds Number Range | Typically high Reynolds number, turbulent regime assumed uniform | Low Reynolds number (Re < 2300) | Laminar flow at low Re; plug flow model used in idealized or turbulent flow |

| Applications | Chemical reactors, tubular reactors, idealized flow assumptions | Microfluidics, viscous flows, precise control applications | Plug flow simplifies reactor design; laminar flow important for low Re systems |

| Velocity Gradient | Zero velocity gradient across cross-section | Significant shear and velocity gradient present | Plug flow has uniform velocity; laminar flow exhibits velocity shear |

Introduction to Plug Flow

Plug flow describes fluid movement where particles travel parallel and at uniform velocity, minimizing axial mixing and maintaining a consistent flow profile. Laminar flow, characterized by smooth, orderly layers with velocity gradients, contrasts with plug flow's flat velocity distribution and reduced shear forces. Understanding plug flow is essential in processes like chemical reactors and microfluidics, where maintaining uniform residence time improves efficiency and reaction consistency.

Understanding Laminar Flow

Laminar flow refers to the smooth, orderly movement of fluid particles in parallel layers with minimal mixing, typically occurring at low Reynolds numbers below 2000. In contrast, plug flow assumes a uniform velocity profile across the flow cross-section, idealizing no velocity gradients and complete mixing in the axial direction, often used in reactor design models. Understanding laminar flow is critical for optimizing microfluidic devices and chemical reactors where precise control of fluid behavior affects reaction efficiency and heat transfer.

Key Differences: Plug Flow vs Laminar Flow

Plug flow features fluid particles moving parallel at a uniform velocity, creating a velocity profile with minimal mixing, whereas laminar flow exhibits smooth, orderly layers with velocity varying across the flow cross-section. In plug flow, the velocity profile is flat, resulting in consistent residence time for all fluid elements, while laminar flow shows a parabolic velocity profile causing different layers to move at varying speeds. Key differences include mixing behavior, velocity distribution, and shear stress, with plug flow promoting plug-like movement ideal for reactors and laminar flow associated with viscous-dominated, low Reynolds number conditions.

Mathematical Models of Plug Flow

Plug flow is characterized by uniform velocity across the pipe cross-section, allowing the use of simplified one-dimensional mathematical models such as the convective transport equation without radial velocity gradients. Unlike laminar flow, which involves parabolic velocity profiles requiring detailed Navier-Stokes solutions, plug flow assumes negligible axial dispersion and can be modeled using the ideal plug flow reactor equation, \( \frac{dC}{dt} = -kC \). This approach enhances computational efficiency in simulating chemical reactors and environmental flows where mixing occurs mainly in the axial direction.

Velocity Profiles in Laminar and Plug Flow

Plug flow exhibits a uniform velocity profile where fluid particles move parallel at constant speed, minimizing mixing across the flow cross-section. In contrast, laminar flow features a parabolic velocity profile, with maximum velocity at the center and zero velocity at the walls due to viscous forces. This difference in velocity distribution profoundly impacts mass transfer, shear stress, and residence time in processes like chemical reactors and microfluidics.

Applications of Plug Flow in Industry

Plug flow is characterized by uniform velocity across the pipe cross-section, minimizing axial mixing and ensuring consistent residence time for fluid particles. In industrial applications such as chemical reactors, wastewater treatment, and food processing, plug flow reactors optimize reaction efficiency and product quality by maintaining controlled flow and precise reaction times. Compared to laminar flow, which exhibits velocity gradients and potential back-mixing, plug flow enhances mass transfer and uniformity critical for processes like polymerization, catalytic reactions, and biochemical fermentations.

Impact on Chemical Reactor Design

Plug flow in chemical reactors ensures uniform velocity and concentration profiles, minimizing axial mixing and enhancing reaction efficiency compared to laminar flow, which exhibits a parabolic velocity profile causing gradient-driven dispersion. The distinct flow patterns influence reactor design, as plug flow reactors (PFRs) enable precise residence time control and higher conversion rates for kinetic-sensitive reactions. Selecting plug flow over laminar flow optimizes reactor volume, heat transfer, and scaling factors, directly impacting throughput and product quality in industrial chemical processes.

Advantages and Disadvantages of Plug Flow

Plug flow reactors provide uniform residence time distribution, enhancing reaction efficiency and product consistency compared to laminar flow systems, which suffer from velocity gradients causing dispersion. The primary advantage of plug flow is its ability to model ideal flow behavior, leading to higher conversion rates in chemical processes, while a notable disadvantage is its sensitivity to channel imperfections and axial mixing that can disrupt the flow profile. Plug flow is preferred in applications requiring precise control of reaction kinetics, but it may require complex design and maintenance to preserve the flow integrity.

Flow Regime Transitions: Laminar to Plug

Flow regime transitions from laminar to plug flow occur when fluid velocity increases, reducing viscous effects and promoting uniform velocity profiles across the pipe or channel cross-section. In laminar flow, fluid layers move parallel with a parabolic velocity distribution, while plug flow features a nearly flat velocity profile with minimal velocity gradients. This transition enhances mass transport efficiency and is critical in designing reactors and pipelines for processes requiring consistent residence times.

Summary and Practical Implications

Plug flow features uniform velocity across the cross-section, minimizing axial mixing and enhancing reaction predictability compared to laminar flow, where velocity varies and creates parabolic profiles with significant mixing. This uniformity in plug flow reactors improves conversion efficiency and selectivity in chemical processing, making them ideal for continuous production systems requiring precise residence time control. In contrast, laminar flow's velocity gradients can cause uneven reactant distribution, impacting reaction rates and product quality in industrial applications.

Plug flow | Laminar flow Infographic

libterm.com

libterm.com