Elasticity measures how much one variable responds to changes in another, commonly seen in economics through price elasticity of demand and supply. Understanding elasticity helps businesses and consumers predict how price changes impact quantity demanded or supplied, enhancing decision-making. Explore the rest of the article to discover how elasticity shapes market dynamics and affects Your financial strategies.

Table of Comparison

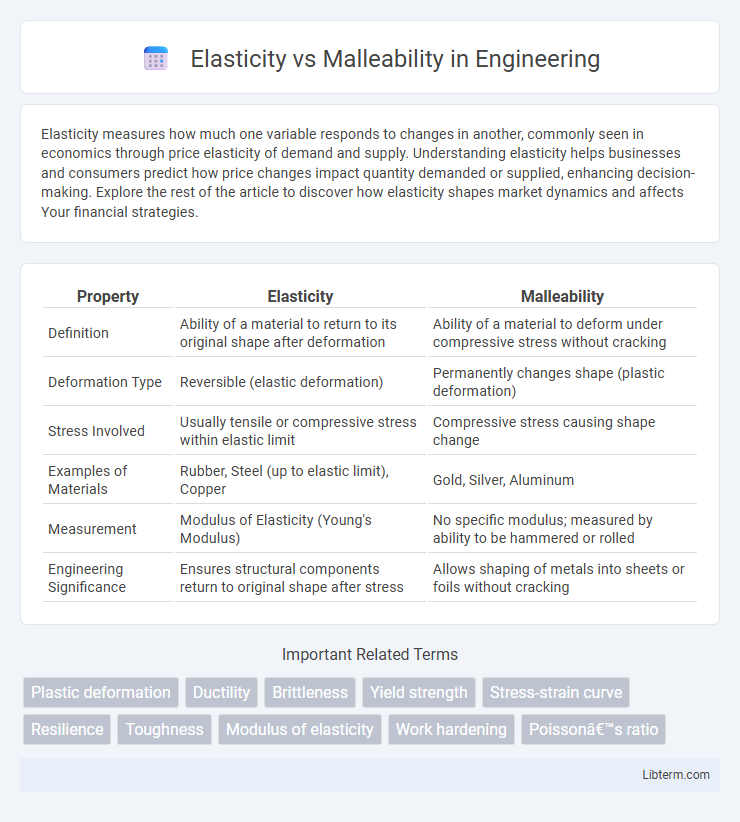

| Property | Elasticity | Malleability |

|---|---|---|

| Definition | Ability of a material to return to its original shape after deformation | Ability of a material to deform under compressive stress without cracking |

| Deformation Type | Reversible (elastic deformation) | Permanently changes shape (plastic deformation) |

| Stress Involved | Usually tensile or compressive stress within elastic limit | Compressive stress causing shape change |

| Examples of Materials | Rubber, Steel (up to elastic limit), Copper | Gold, Silver, Aluminum |

| Measurement | Modulus of Elasticity (Young's Modulus) | No specific modulus; measured by ability to be hammered or rolled |

| Engineering Significance | Ensures structural components return to original shape after stress | Allows shaping of metals into sheets or foils without cracking |

Introduction to Elasticity and Malleability

Elasticity refers to a material's ability to return to its original shape and size after the removal of applied stress, measured by the elastic limit and modulus of elasticity. Malleability describes a material's capacity to deform under compressive stress, allowing it to be hammered or rolled into thin sheets without breaking. Both properties are essential in material science for understanding how metals and alloys respond to mechanical forces in manufacturing and structural applications.

Defining Elasticity: Key Characteristics

Elasticity refers to a material's ability to return to its original shape and size after the removal of an applied force, highlighting its reversible deformation property. Key characteristics of elasticity include the proportional relationship between stress and strain within the elastic limit and the absence of permanent deformation upon unloading. Unlike malleability, which describes a material's capacity to be permanently shaped under compressive stress, elasticity emphasizes temporary shape changes and energy storage.

Defining Malleability: Essential Properties

Malleability refers to a material's ability to deform under compressive stress, allowing it to be hammered or rolled into thin sheets without breaking. This property is essential for metals like gold, silver, and copper, which exhibit high malleability due to their metallic bonding and atomic structure. Understanding malleability helps in selecting materials for manufacturing processes such as sheet metal fabrication and metal forming.

Differences Between Elasticity and Malleability

Elasticity refers to a material's ability to return to its original shape after deformation when the applied force is removed, while malleability describes a material's capacity to be permanently deformed under compressive stress without breaking. Elasticity is commonly measured by the elastic modulus or Young's modulus, indicating how much a material stretches or compresses, whereas malleability is assessed by the extent a material can be hammered or rolled into thin sheets. Metals like rubber exhibit high elasticity, whereas metals like gold and copper display significant malleability.

Physical Examples of Elastic Materials

Elastic materials such as rubber bands, steel springs, and nylon fibers exhibit the ability to return to their original shape after deformation due to their molecular structure. When stretched or compressed, these materials store potential energy and demonstrate high elasticity, making them ideal for applications requiring flexibility and recovery. Examples include the use of rubber in tires, steel in suspension systems, and nylon in fabric, where resilience to repeated stress is essential.

Real-World Applications of Malleable Materials

Malleable materials, such as gold, copper, and aluminum, are widely used in real-world applications requiring shaping without breaking, including jewelry making, electrical wiring, and automotive body panels. Their ability to undergo extensive plastic deformation under compressive stress enables manufacturing processes like rolling, hammering, and pressing. In contrast to elasticity, which involves temporary shape recovery, malleability allows permanent reshaping essential for customizable and durable products.

Importance in Material Science

Elasticity is crucial in material science for designing components that can return to their original shape after deformation, ensuring durability and structural integrity under stress. Malleability allows materials to be shaped or formed without breaking, which is vital for manufacturing processes like forging and rolling. Understanding the balance between elasticity and malleability helps engineers select materials that meet specific mechanical requirements and optimize performance in applications ranging from aerospace to automotive industries.

Testing Methods for Elasticity and Malleability

Testing methods for elasticity often involve stress-strain analysis using tensile tests, where materials are stretched and their ability to return to original shape is measured. Malleability testing typically employs compressive tests, such as hammering or rolling, to determine how much a material can deform under pressure without cracking. Both testing methods utilize specialized equipment like universal testing machines and hardness testers to quantify mechanical properties accurately.

Impact on Industrial Uses and Manufacturing

Elasticity enables materials like rubber and steel to return to their original shape after deformation, enhancing durability and reducing material fatigue in industrial applications such as automotive suspension systems and flexible electronics. Malleability allows metals such as gold, aluminum, and copper to be shaped and molded without cracking, critical for manufacturing processes like sheet metal fabrication and intricate component design. The balance between elasticity and malleability influences material selection for products requiring both formability and resilience, impacting efficiency and cost-effectiveness in manufacturing workflows.

Conclusion: Choosing the Right Material for the Job

Elasticity measures a material's ability to return to its original shape after deformation, while malleability indicates how easily it can be shaped or hammered without breaking. Materials with high elasticity, such as rubber, are ideal for applications requiring flexibility and shape recovery, whereas malleable metals like gold and copper excel in processes involving shaping or molding. Selecting the right material depends on the specific demands of the task, balancing the need for mechanical resilience with ease of fabrication.

Elasticity Infographic

libterm.com

libterm.com