Crack initiation occurs when stress concentrations exceed the material's strength, leading to microscopic fractures that serve as the starting point for crack growth. Understanding the factors influencing crack initiation, such as material properties, surface defects, and loading conditions, is essential for preventing premature failure in structures. Explore the rest of the article to learn how to detect and control crack initiation in your engineering applications.

Table of Comparison

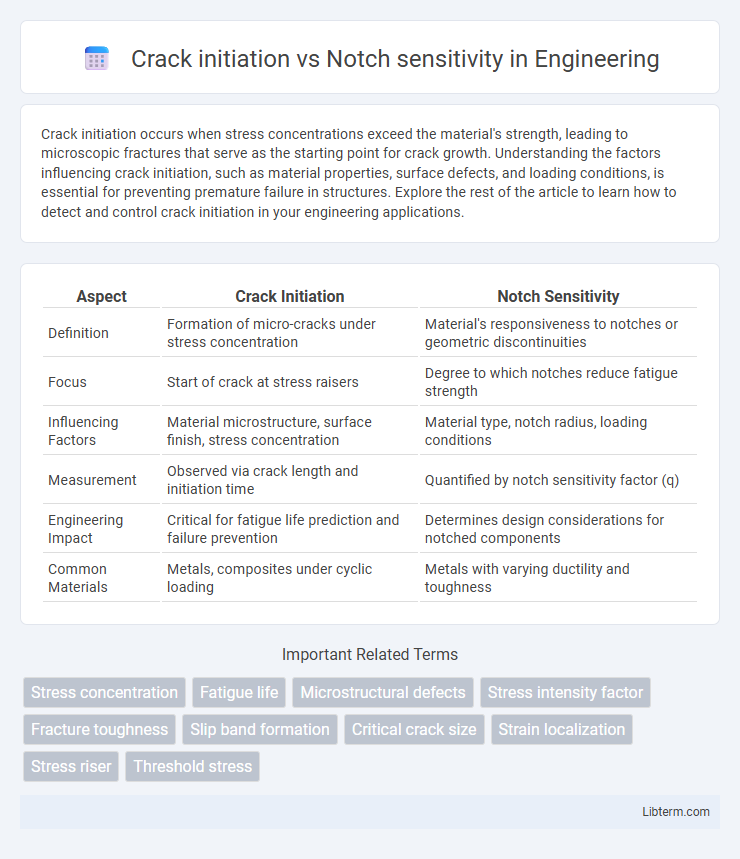

| Aspect | Crack Initiation | Notch Sensitivity |

|---|---|---|

| Definition | Formation of micro-cracks under stress concentration | Material's responsiveness to notches or geometric discontinuities |

| Focus | Start of crack at stress raisers | Degree to which notches reduce fatigue strength |

| Influencing Factors | Material microstructure, surface finish, stress concentration | Material type, notch radius, loading conditions |

| Measurement | Observed via crack length and initiation time | Quantified by notch sensitivity factor (q) |

| Engineering Impact | Critical for fatigue life prediction and failure prevention | Determines design considerations for notched components |

| Common Materials | Metals, composites under cyclic loading | Metals with varying ductility and toughness |

Introduction to Crack Initiation and Notch Sensitivity

Crack initiation refers to the localized development of micro-cracks at stress concentration points, typically influenced by material defects and surface irregularities. Notch sensitivity measures a material's susceptibility to crack initiation due to the presence of geometric discontinuities or notches. Understanding the interplay between crack initiation and notch sensitivity is critical for predicting component durability and preventing premature failure in structural applications.

Fundamental Concepts: Crack Initiation Explained

Crack initiation refers to the early stage in the failure process where microscopic cracks form due to stress concentration, often at material discontinuities like notches or surface defects. Notch sensitivity quantifies a material's tendency to experience reduced strength or increased crack initiation risk in the presence of geometrical discontinuities. Understanding crack initiation mechanisms involves analyzing stress intensity factors and material microstructure to predict fatigue life accurately in engineering components.

Defining Notch Sensitivity in Materials

Notch sensitivity in materials quantifies the extent to which the presence of a notch or geometric discontinuity reduces a material's strength or fatigue life by concentrating stress and promoting crack initiation. It is defined by the ratio of fatigue strength of a smooth specimen to that of a notched specimen, reflecting how susceptible a material is to stress concentrations at notches. Materials with high notch sensitivity exhibit significant reductions in fatigue strength and earlier crack initiation, while low notch-sensitive materials maintain performance despite the presence of notches.

Mechanisms Behind Crack Initiation

Crack initiation primarily occurs due to localized stress concentration and cyclic loading effects at microscopic material defects or surface discontinuities. Notch sensitivity influences crack initiation by amplifying stress intensity around geometric irregularities, accelerating the onset of microcracks. Understanding the interplay between microstructural features and notch effects is critical for predicting fatigue life and improving material durability.

Factors Influencing Notch Sensitivity

Notch sensitivity is primarily influenced by material properties such as ductility, grain size, and strain hardening capacity, which affect the material's ability to redistribute stresses around a notch. The presence of residual stresses and the geometry of the notch, including notch radius and depth, significantly impact crack initiation by concentrating stresses at the notch tip. Environmental factors like temperature and corrosive conditions also alter notch sensitivity by affecting the material's fracture toughness and fatigue resistance.

Testing Methods for Crack Initiation and Notch Sensitivity

Testing methods for crack initiation commonly involve fatigue crack growth experiments using specimens with pre-existing micro-cracks, employing techniques such as cyclic loading and stress intensity factor measurements to determine the onset of crack propagation. Notch sensitivity assessment typically uses standardized tensile testing on notched specimens, evaluating the reduction in material strength or fatigue life caused by the notch, while fracture mechanics approaches quantify stress concentration effects via notch acuity and geometry. Advanced non-destructive evaluation methods like acoustic emission and digital image correlation are increasingly utilized to monitor crack initiation and notch sensitivity in real time under operational loading conditions.

Material Properties Affecting Both Phenomena

Crack initiation and notch sensitivity are both critically influenced by material properties such as toughness, ductility, and microstructural features. Materials with high toughness and ductility typically exhibit delayed crack initiation and reduced notch sensitivity due to their enhanced ability to undergo plastic deformation and absorb stress concentration effects. Grain size, phase distribution, and the presence of inclusions or defects significantly affect local stress distribution, impacting both the initiation of cracks and the material's notch sensitivity under mechanical loading.

Comparative Analysis: Crack Initiation vs Notch Sensitivity

Crack initiation refers to the point at which a material begins to develop microscopic cracks under stress, while notch sensitivity measures a material's susceptibility to crack formation at stress concentrators such as notches or geometrical discontinuities. Materials with high notch sensitivity exhibit significant reductions in strength due to stress concentration effects that accelerate crack initiation compared to materials with low notch sensitivity, which better resist crack formation. Comparative analysis shows that understanding the interplay between crack initiation mechanisms and notch sensitivity is critical for predicting fatigue life and optimizing design in structural applications.

Real-World Applications and Case Studies

Crack initiation and notch sensitivity are critical factors in fatigue analysis of engineering components such as aerospace turbine blades and automotive suspension parts, where microstructural stress concentrators influence lifespan. Real-world case studies reveal that materials with low notch sensitivity, like certain titanium alloys, exhibit enhanced durability under cyclic loading despite geometric discontinuities. Understanding the interplay between crack initiation sites and notch sensitivity enables optimized design strategies to mitigate premature failure in structural applications.

Strategies to Minimize Crack Initiation and Notch Sensitivity

Minimizing crack initiation and notch sensitivity involves optimizing material selection and geometrical design to reduce stress concentrations. Employing surface treatments such as shot peening or laser peening enhances residual compressive stresses, delaying crack initiation at notches. Incorporating toughening mechanisms like microalloying or grain refinement improves resistance to crack propagation and decreases notch sensitivity in critical components.

Crack initiation Infographic

libterm.com

libterm.com