Liquid penetrant testing is a nondestructive inspection method used to detect surface-breaking defects in materials such as cracks, porosity, and laps. This technique involves applying a liquid dye to the surface, allowing it to seep into flaws, and then removing excess liquid before applying a developer to draw out the penetrant for visual inspection. Explore the rest of the article to understand how liquid penetrant testing can enhance your quality control processes effectively.

Table of Comparison

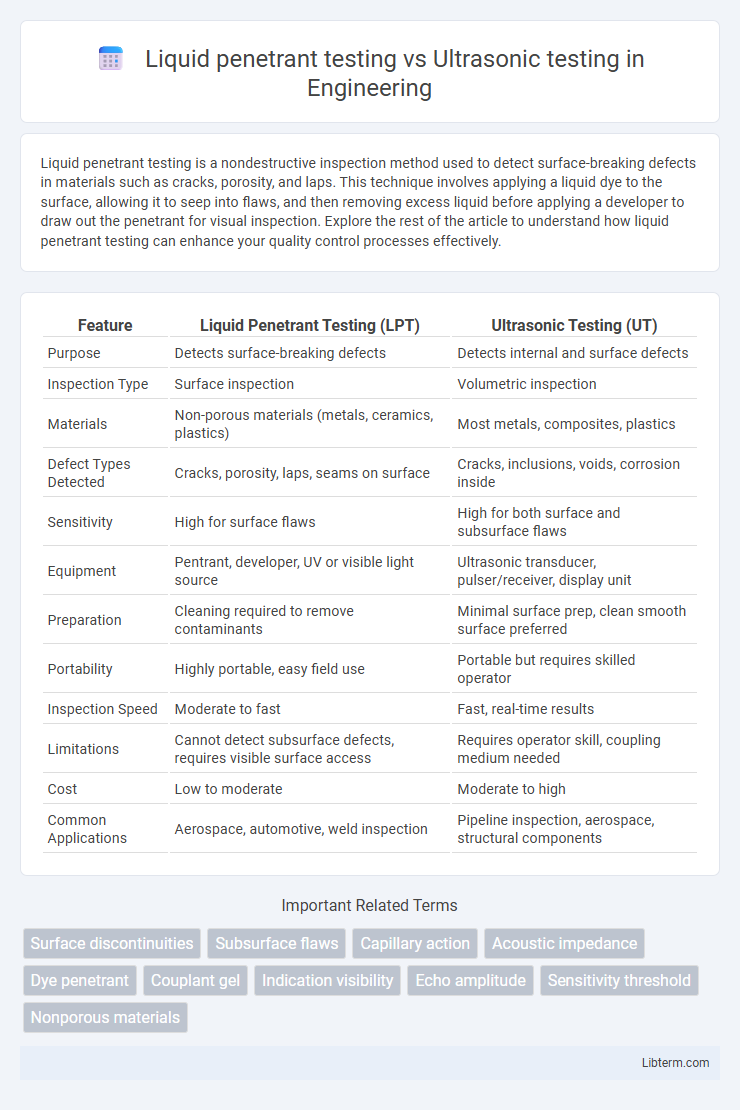

| Feature | Liquid Penetrant Testing (LPT) | Ultrasonic Testing (UT) |

|---|---|---|

| Purpose | Detects surface-breaking defects | Detects internal and surface defects |

| Inspection Type | Surface inspection | Volumetric inspection |

| Materials | Non-porous materials (metals, ceramics, plastics) | Most metals, composites, plastics |

| Defect Types Detected | Cracks, porosity, laps, seams on surface | Cracks, inclusions, voids, corrosion inside |

| Sensitivity | High for surface flaws | High for both surface and subsurface flaws |

| Equipment | Pentrant, developer, UV or visible light source | Ultrasonic transducer, pulser/receiver, display unit |

| Preparation | Cleaning required to remove contaminants | Minimal surface prep, clean smooth surface preferred |

| Portability | Highly portable, easy field use | Portable but requires skilled operator |

| Inspection Speed | Moderate to fast | Fast, real-time results |

| Limitations | Cannot detect subsurface defects, requires visible surface access | Requires operator skill, coupling medium needed |

| Cost | Low to moderate | Moderate to high |

| Common Applications | Aerospace, automotive, weld inspection | Pipeline inspection, aerospace, structural components |

Introduction to Liquid Penetrant and Ultrasonic Testing

Liquid penetrant testing detects surface-breaking defects by applying a visible or fluorescent dye that seeps into cracks and discontinuities, making flaws easily identifiable under proper lighting. Ultrasonic testing employs high-frequency sound waves to detect internal flaws and measure material thickness by analyzing sound wave reflections from imperfections. Both non-destructive testing methods offer distinct advantages in identifying defects, with liquid penetrant best suited for surface flaws and ultrasonic testing ideal for subsurface and volumetric inspections.

Fundamental Principles of Each Testing Method

Liquid penetrant testing relies on the capillary action of a visible or fluorescent dye to seep into surface-breaking defects, revealing imperfections when excess dye is removed and a developer is applied. Ultrasonic testing uses high-frequency sound waves transmitted into a material, detecting internal flaws by analyzing the reflected wave signals from discontinuities. Both methods fundamentally differ as liquid penetrant testing is surface-sensitive while ultrasonic testing evaluates subsurface integrity.

Types of Defects Detected

Liquid penetrant testing excels at detecting surface-breaking defects such as cracks, porosity, and laps by highlighting discontinuities open to the surface with visible or fluorescent dyes. Ultrasonic testing penetrates beneath the surface, identifying internal flaws including volumetric defects like voids, inclusions, and delaminations, as well as planar defects such as cracks and lack of fusion. Both methods complement each other, with liquid penetrant best suited for surface imperfections and ultrasonic testing providing comprehensive internal defect detection.

Suitable Materials for Inspection

Liquid penetrant testing is ideal for inspecting non-porous materials such as metals, ceramics, and plastics, especially those with smooth surfaces where surface-breaking defects like cracks and porosity need detection. Ultrasonic testing excels in examining a wide range of materials including metals, composites, and welds, effectively identifying internal flaws such as inclusions, voids, and thickness variations in both homogeneous and heterogeneous materials. The selection between these methods depends on material type and defect location, with liquid penetrant optimized for surface flaws in non-porous substances, and ultrasonic suitable for internal flaw detection in diverse materials.

Surface vs. Subsurface Flaw Detection

Liquid penetrant testing excels in detecting surface flaws, such as cracks and porosity, by revealing discontinuities visible on the material's exterior. Ultrasonic testing provides superior subsurface flaw detection by using high-frequency sound waves to identify internal defects like voids, inclusions, or cracks beneath the surface. Combining both methods enhances comprehensive inspection by covering both surface and subsurface flaw identification effectively.

Equipment and Process Requirements

Liquid penetrant testing requires surface preparation equipment, penetrant application tools, and UV or visible light inspection lamps to detect surface-breaking defects, while ultrasonic testing involves ultrasonic transducers, couplant gels, and advanced signal processing devices to evaluate internal material flaws. The liquid penetrant process demands controlled surface cleanliness and drying stages, whereas ultrasonic testing relies on precise calibration and coupling techniques to transmit high-frequency sound waves into the material. Equipment complexity and operator skill levels are typically higher for ultrasonic testing due to the need for interpreting waveform data, compared to the more straightforward visual inspection in liquid penetrant testing.

Sensitivity and Accuracy Comparison

Liquid penetrant testing (LPT) excels in detecting surface-breaking defects with high sensitivity, revealing fine cracks and porosities on non-porous materials. Ultrasonic testing (UT) offers superior accuracy for subsurface flaw detection, providing precise depth and size measurements through sound wave reflection analysis. While LPT is limited to surface flaws, UT's capability to evaluate internal structures makes it highly effective for comprehensive defect characterization.

Application Scenarios and Industry Use

Liquid penetrant testing excels in detecting surface-breaking defects in non-porous materials, making it ideal for aerospace, automotive, and manufacturing industries focusing on weld inspection and casting quality. Ultrasonic testing penetrates deeper materials, identifying internal flaws such as cracks and voids, widely used in oil and gas pipelines, power generation, and aerospace structural integrity assessments. Both methods complement each other by covering surface and subsurface defect detection, optimizing quality control across critical sectors.

Advantages and Limitations

Liquid penetrant testing offers high sensitivity for detecting surface-breaking defects and is cost-effective for inspecting non-porous materials like metals and ceramics. Ultrasonic testing excels in identifying internal flaws and thickness measurements with precise depth information, but it requires skilled operators and equipment calibration. Limitations of liquid penetrant testing include its inability to detect subsurface defects, while ultrasonic testing may struggle with complex geometries and materials with high attenuation.

Safety and Environmental Considerations

Liquid penetrant testing (LPT) involves the use of chemical dyes that can pose health risks through skin contact and inhalation, requiring proper ventilation and protective gear to ensure worker safety. Ultrasonic testing (UT) is a non-invasive method that eliminates chemical exposure, enhancing safety while minimizing environmental impact by avoiding hazardous waste generation. Both methods demand adherence to regulatory standards, but UT is generally favored for its eco-friendliness and reduced occupational hazards.

Liquid penetrant testing Infographic

libterm.com

libterm.com