Hall effect sensors detect magnetic fields by measuring voltage changes caused by magnetic flux, enabling precise position and speed sensing in various applications. Their compact size and contactless operation make them ideal for automotive, industrial, and consumer electronics. Discover how this technology can enhance Your devices by reading the rest of the article.

Table of Comparison

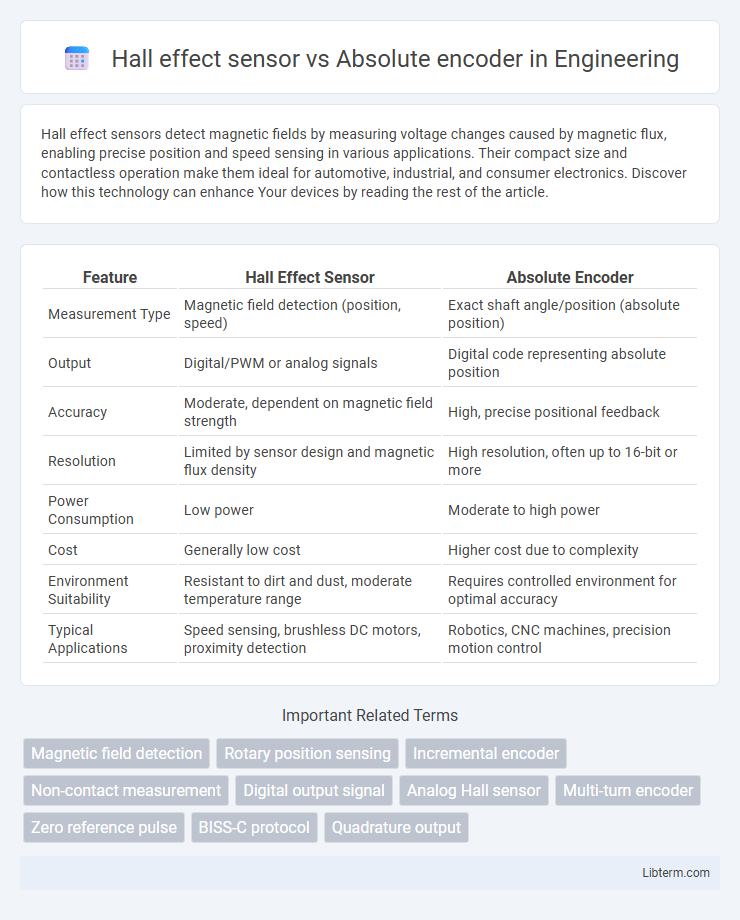

| Feature | Hall Effect Sensor | Absolute Encoder |

|---|---|---|

| Measurement Type | Magnetic field detection (position, speed) | Exact shaft angle/position (absolute position) |

| Output | Digital/PWM or analog signals | Digital code representing absolute position |

| Accuracy | Moderate, dependent on magnetic field strength | High, precise positional feedback |

| Resolution | Limited by sensor design and magnetic flux density | High resolution, often up to 16-bit or more |

| Power Consumption | Low power | Moderate to high power |

| Cost | Generally low cost | Higher cost due to complexity |

| Environment Suitability | Resistant to dirt and dust, moderate temperature range | Requires controlled environment for optimal accuracy |

| Typical Applications | Speed sensing, brushless DC motors, proximity detection | Robotics, CNC machines, precision motion control |

Introduction to Hall Effect Sensors and Absolute Encoders

Hall effect sensors detect magnetic fields by measuring voltage changes caused by a magnetic flux, enabling precise position sensing in various applications. Absolute encoders provide unique digital position values for each shaft angle, ensuring accurate and reliable motion control without requiring a reference point. Both technologies are essential in robotics and industrial automation for precise rotational position feedback and motion tracking.

Basic Operating Principles

Hall effect sensors detect magnetic fields by measuring the voltage generated across a conductor when exposed to a magnetic flux, enabling position or speed sensing through changes in magnetic field strength. Absolute encoders use optical or magnetic sensing to provide a unique digital code corresponding to each shaft position, allowing precise and non-volatile position measurement. While Hall effect sensors primarily offer relative position data, absolute encoders deliver exact angular position information without requiring reference movement.

Key Differences in Sensing Mechanisms

Hall effect sensors detect magnetic field changes by measuring voltage variations caused by the Hall effect, offering contactless and linear position sensing ideal for rotational speed and current detection. Absolute encoders provide unique digital position values by reading coded magnetic or optical patterns, enabling precise angular position measurement without cumulative error. The fundamental difference lies in Hall effect sensors measuring magnetic field intensity for relative motion data, while absolute encoders deliver exact position information through direct pattern recognition.

Accuracy and Resolution Comparison

Hall effect sensors provide moderate accuracy and resolution, typically suited for applications requiring basic position sensing with resolutions up to 12 bits. Absolute encoders offer superior accuracy and high resolution, often exceeding 16 bits, enabling precise angular position measurement and eliminating any loss of position after power cycles. The choice between the two depends on the specific application demands for precision, reliability, and cost efficiency.

Durability and Environmental Resistance

Hall effect sensors offer superior durability and environmental resistance due to their solid-state design, which makes them highly resistant to shock, vibration, and extreme temperatures. Absolute encoders often incorporate mechanical components that can be more vulnerable to wear and environmental factors such as dust and moisture. In demanding industrial settings, Hall effect sensors provide more reliable performance over time, especially in harsh or contaminated environments.

Output Signal Types and Interfaces

Hall effect sensors produce analog or digital output signals based on magnetic field changes, commonly using open-collector, open-drain, or push-pull interfaces compatible with microcontrollers and industrial systems. Absolute encoders provide multi-bit digital output signals, often through serial communication protocols like SSI, BiSS, or parallel interfaces, enabling precise position feedback with unique code values for each shaft position. The choice between these sensors depends on output signal resolution and interface requirements, with Hall effect sensors favoring simple binary or PWM signals and absolute encoders delivering complex, high-resolution digital data streams.

Typical Applications and Use Cases

Hall effect sensors are commonly employed in automotive systems for wheel speed detection, brushless DC motor commutation, and proximity sensing due to their ability to detect magnetic fields with high reliability. Absolute encoders deliver precise position feedback in industrial automation, robotics, and CNC machinery, where exact angular or linear position measurement is critical for closed-loop control systems. Both devices serve motion control applications, but Hall effect sensors excel in speed and rotational direction sensing while absolute encoders provide unique positional data without requiring homing procedures.

Installation and Calibration Requirements

Hall effect sensors offer simpler installation and require minimal calibration due to their contactless operation and straightforward wiring. Absolute encoders demand precise alignment during installation and often need initial calibration to ensure accurate position readings from the start. Proper calibration of absolute encoders is critical to maintain absolute positioning accuracy across power cycles, whereas Hall effect sensors primarily rely on stable magnetic field placement.

Cost Analysis and Budget Considerations

Hall effect sensors generally offer a lower-cost solution compared to absolute encoders, making them ideal for budget-sensitive applications requiring basic position detection. Absolute encoders, while more expensive, provide precise and reliable position feedback, justifying their higher upfront investment in complex or safety-critical systems. Evaluating total cost of ownership should include initial purchase price, installation complexity, and long-term maintenance expenses for optimal budget planning.

Choosing the Right Technology for Your Application

Hall effect sensors offer precise magnetic field detection with excellent durability, making them ideal for applications requiring contactless position sensing in harsh environments. Absolute encoders provide unique positional data for each shaft position, ensuring accurate and reliable feedback critical for complex motion control systems. Selecting between the two depends on factors such as required accuracy, environmental conditions, and system complexity, with Hall effect sensors excelling in simplicity and robustness, while absolute encoders deliver higher precision and absolute position information.

Hall effect sensor Infographic

libterm.com

libterm.com