A uniformly distributed load (UDL) is a type of load that is spread evenly across the length of a structural element, such as a beam or slab, resulting in a constant intensity of force per unit length. This load distribution causes bending moments and shear forces that must be accurately calculated to ensure structural safety and performance. Explore the rest of this article to understand how uniformly distributed loads affect structural design and analysis.

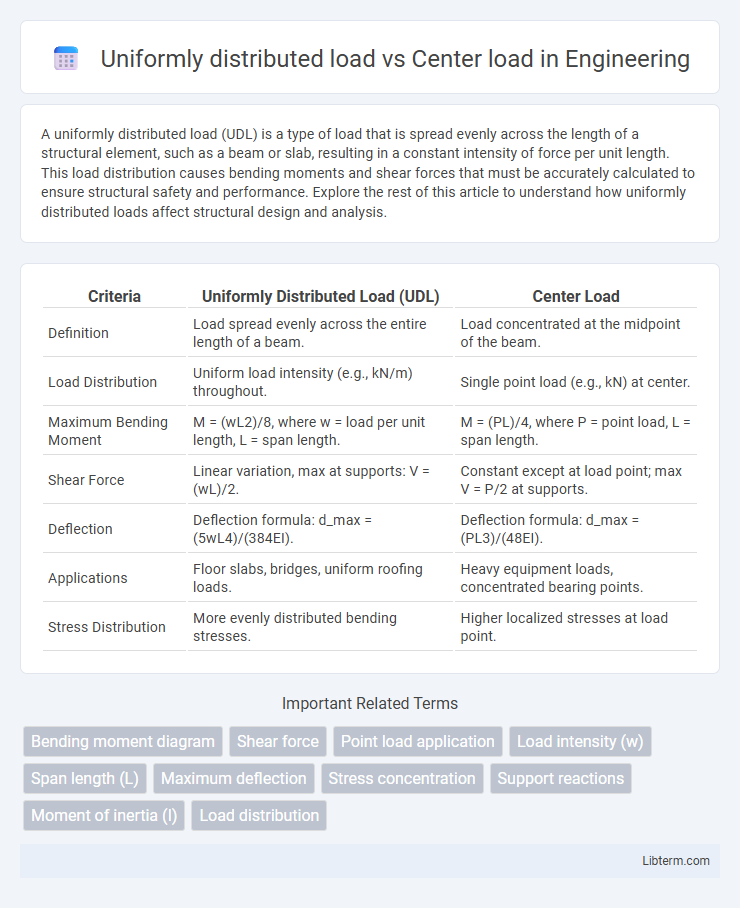

Table of Comparison

| Criteria | Uniformly Distributed Load (UDL) | Center Load |

|---|---|---|

| Definition | Load spread evenly across the entire length of a beam. | Load concentrated at the midpoint of the beam. |

| Load Distribution | Uniform load intensity (e.g., kN/m) throughout. | Single point load (e.g., kN) at center. |

| Maximum Bending Moment | M = (wL2)/8, where w = load per unit length, L = span length. | M = (PL)/4, where P = point load, L = span length. |

| Shear Force | Linear variation, max at supports: V = (wL)/2. | Constant except at load point; max V = P/2 at supports. |

| Deflection | Deflection formula: d_max = (5wL4)/(384EI). | Deflection formula: d_max = (PL3)/(48EI). |

| Applications | Floor slabs, bridges, uniform roofing loads. | Heavy equipment loads, concentrated bearing points. |

| Stress Distribution | More evenly distributed bending stresses. | Higher localized stresses at load point. |

Introduction to Load Types in Structural Engineering

Uniformly distributed load (UDL) applies a constant force per unit length across a structural element, commonly seen in snow loads on roofs or floor loads in buildings. Center load concentrates the entire force at a single point, often representing heavy equipment or column reactions on beams. Understanding these load types is crucial for accurate structural analysis and design, ensuring safe and efficient load-bearing capacity.

Defining Uniformly Distributed Load (UDL)

Uniformly Distributed Load (UDL) refers to a load spread evenly across a length or surface, causing consistent pressure or force per unit area, measured typically in Newtons per meter (N/m). Unlike a Center Load, which applies force at a single point, UDL results in a continuous bending moment and shear force distribution along the entire structural element. Engineers use UDL to model real-world scenarios like roof loads, floor loads, or snow loads that affect beams or slabs uniformly for accurate stress and deflection analysis.

Understanding Center (Point) Load

Center load, also known as point load, applies force at a single, specific point on a structural element, causing maximum bending moment at the load location. Uniformly distributed load spreads force evenly across the entire length of the beam, resulting in a varying bending moment along the span. Understanding center load is crucial for designing supports and calculating shear forces, as it creates concentrated stress and deflection directly under the load.

Key Differences Between UDL and Center Load

A uniformly distributed load (UDL) applies a consistent force across the entire length of a beam, resulting in a linear variation of bending moments and shear forces, while a center load concentrates the entire force at a single central point, causing maximum bending moment at the load location. UDL typically produces a parabolic bending moment diagram and uniform shear distribution, whereas a center load generates triangular shear force diagrams and concentrated maximum stress directly under the load. Structural analysis for UDL involves integrating the load over the span, whereas center load calculations focus on point load effects, influencing design choices and support reactions differently.

Effects on Structural Elements

Uniformly distributed loads create a consistent bending moment and shear force along the length of beams, resulting in evenly spread stress that enhances structural stability. Center loads induce maximum bending moment and shear force at the midpoint, causing higher localized stress and potential deflection. Structural elements under uniformly distributed loads typically experience lower peak stresses compared to those under center loads, influencing design considerations for strength and flexibility.

Bending Moment and Shear Force Comparison

Uniformly distributed loads produce a linear variation in shear force across the beam length, resulting in a parabolic bending moment diagram with the maximum moment at mid-span. In contrast, a center load creates a sudden jump in shear force at the load point and generates a triangular bending moment diagram, also peaking at mid-span but with a higher maximum moment compared to an equivalent total uniformly distributed load. The maximum bending moment for a center load P on a simply supported beam of length L is (P x L)/4, whereas for a uniformly distributed load w, it is (w x L2)/8, highlighting the impact of load type on structural response.

Design Implications of UDL vs Center Load

Uniformly distributed load (UDL) spreads the force evenly across a beam, reducing maximum bending moments and deflections compared to a center load which concentrates all force at a single point. In design, UDLs require calculations based on load intensity per unit length, influencing beam size and reinforcement distribution for consistent stress management. Center loads demand higher moment capacity at the load point, often necessitating localized strengthening and more robust support conditions to prevent failure.

Real-World Applications and Examples

Uniformly distributed loads (UDLs) are commonly used in structural engineering scenarios such as floor slabs, bridge decks, and roof beams where weight is spread evenly across a surface, ensuring consistent stress distribution and minimizing localized failure. Center loads occur in applications like column loads, crane hooks, and simple beam testing, introducing high stress concentration at a single point which requires robust reinforcement design to prevent structural failure. Practical examples include the even snow load on a flat roof representing a UDL, while a parked crane applying a load at a specific point on a bridge beam exemplifies a center load scenario.

Advantages and Limitations of Each Load Type

Uniformly distributed loads (UDL) provide a consistent pressure across the entire surface, resulting in evenly distributed stress that reduces the risk of localized failures, making them ideal for structural elements like beams and slabs. A limitation of UDL is the increased material requirement and weight due to continuous loading, which can lead to higher construction costs and potential overdesign. Center loads concentrate force at a single point, offering simple load application and easier calculation of bending moments, but this leads to high stress concentration, increasing the risk of structural failure near the load application point.

Conclusion: Choosing the Appropriate Load Distribution

Selecting between uniformly distributed load and center load depends on the structural application and load characteristics; uniformly distributed loads spread force evenly along a beam, reducing bending stress and deflection. Center loads concentrate force at a single point, causing higher localized stress and potential for greater deflection but are simpler to analyze. Engineers prioritize uniformly distributed loads for consistent performance and center loads for scenarios requiring analysis of peak stress effects.

Uniformly distributed load Infographic

libterm.com

libterm.com