Wireless power transfer enables the transmission of electrical energy without physical connectors, using electromagnetic fields to charge devices remotely. This technology improves convenience and efficiency by eliminating cables and allowing multiple devices to charge simultaneously. Explore the rest of the article to discover how wireless power transfer can revolutionize your charging experience.

Table of Comparison

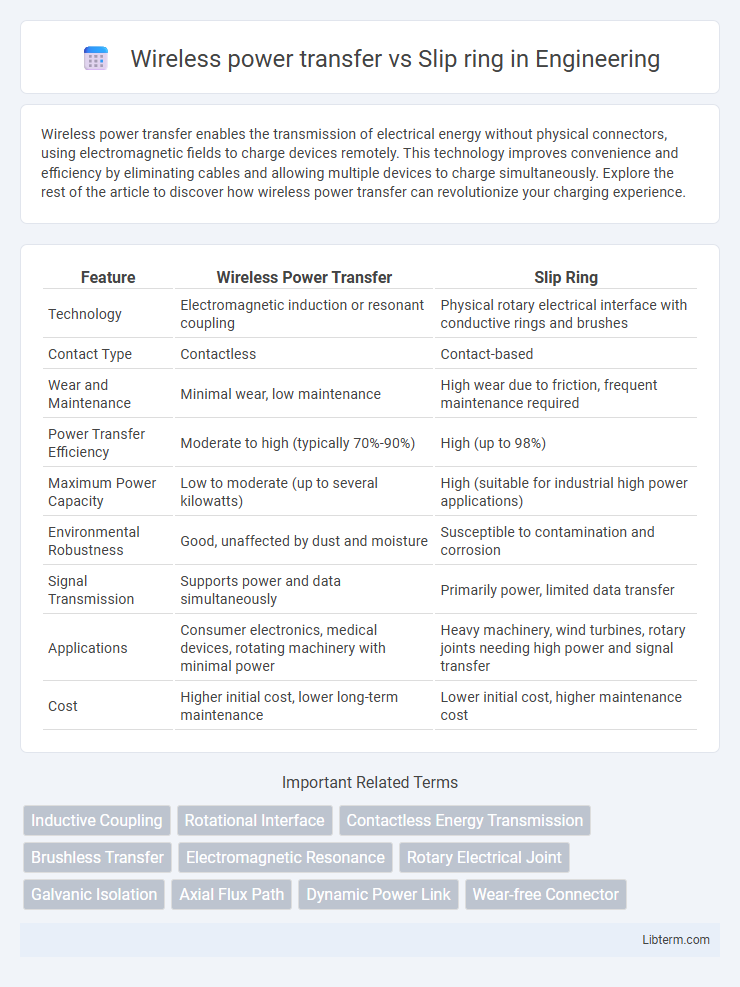

| Feature | Wireless Power Transfer | Slip Ring |

|---|---|---|

| Technology | Electromagnetic induction or resonant coupling | Physical rotary electrical interface with conductive rings and brushes |

| Contact Type | Contactless | Contact-based |

| Wear and Maintenance | Minimal wear, low maintenance | High wear due to friction, frequent maintenance required |

| Power Transfer Efficiency | Moderate to high (typically 70%-90%) | High (up to 98%) |

| Maximum Power Capacity | Low to moderate (up to several kilowatts) | High (suitable for industrial high power applications) |

| Environmental Robustness | Good, unaffected by dust and moisture | Susceptible to contamination and corrosion |

| Signal Transmission | Supports power and data simultaneously | Primarily power, limited data transfer |

| Applications | Consumer electronics, medical devices, rotating machinery with minimal power | Heavy machinery, wind turbines, rotary joints needing high power and signal transfer |

| Cost | Higher initial cost, lower long-term maintenance | Lower initial cost, higher maintenance cost |

Introduction to Wireless Power Transfer and Slip Rings

Wireless power transfer (WPT) enables the transmission of electrical energy without physical connectors, using electromagnetic fields or inductive coupling, making it ideal for applications requiring contactless energy delivery. Slip rings provide a mechanical means to transmit power and signals between stationary and rotating components, relying on conductive brushes and rings to maintain electrical continuity in rotating machinery. Comparing WPT and slip rings highlights the advantages of wireless solutions in reducing wear and maintenance, while slip rings remain essential in scenarios demanding robust, high-current connections in rotational systems.

Basic Principles of Wireless Power Transfer

Wireless power transfer (WPT) operates on the principle of electromagnetic fields to transmit energy without physical connectors, using methods like inductive coupling, resonant inductive coupling, and capacitive coupling. In contrast, slip rings transfer electrical signals and power through direct mechanical contact via rotating conductive rings and brushes, enabling continuous rotation of connected parts. WPT eliminates wear and maintenance issues associated with slip rings by enabling contactless energy transmission, enhancing reliability and reducing mechanical friction.

How Slip Rings Work

Slip rings operate by transmitting electrical signals and power through conductive rings and brushes, enabling continuous rotation without interrupting the connection. These mechanical components allow for the transfer of AC or DC current to rotating parts, commonly found in electric generators, wind turbines, and rotating cameras. Unlike wireless power transfer that uses electromagnetic fields for contactless energy transmission, slip rings rely on physical contact, which may introduce wear and maintenance challenges over time.

Key Differences Between Wireless Power Transfer and Slip Rings

Wireless power transfer uses electromagnetic fields to transmit energy without physical contact, enhancing durability and reducing maintenance compared to slip rings, which rely on mechanical contact through rotating conductive rings and brushes. Wireless systems support higher rotational speeds and minimize wear, while slip rings enable continuous power and signal transmission but are prone to friction-related issues and limited lifespan. The choice between these technologies depends on application requirements like rotational speed, maintenance capacity, and environmental conditions.

Applications of Wireless Power Transfer

Wireless power transfer (WPT) is widely applied in charging electric vehicles, enabling seamless energy delivery without physical connectors, making it ideal for moving or rotating parts. It is extensively used in biomedical implants, providing safe, reliable power to devices like pacemakers without invasive wires, enhancing patient comfort and mobility. Consumer electronics also benefit from WPT through wireless charging pads for smartphones and wearables, promoting convenience and reducing cable clutter.

Applications of Slip Rings

Slip rings are widely used in applications requiring the transfer of electrical signals and power between stationary and rotating parts, such as wind turbines, windmill generators, and industrial rotary tables. They enable continuous rotation while transmitting power, data, and control signals in sectors like aerospace, robotics, and medical imaging equipment. Compared to wireless power transfer, slip rings offer a reliable solution for high-current and high-voltage applications where stable and uninterrupted electrical connectivity is essential.

Advantages of Wireless Power Transfer Over Slip Rings

Wireless power transfer eliminates mechanical wear and maintenance issues associated with slip rings by providing contactless energy transmission, enhancing system reliability and lifespan. It enables higher rotational speeds and reduces electromagnetic interference by avoiding physical brushes and rings. Wireless power offers increased design flexibility and safety, making it ideal for applications in harsh or sealed environments where slip rings may fail.

Limitations and Challenges of Both Technologies

Wireless power transfer faces limitations such as reduced efficiency over distance, susceptibility to interference, and challenges with alignment between transmitter and receiver coils. Slip rings encounter mechanical wear and tear, electrical noise generation, and maintenance complexities due to their rotating contact design. Both technologies struggle with power loss and reliability issues in demanding industrial or high-speed applications.

Choosing the Right Technology for Your Application

Wireless power transfer offers a contactless solution that reduces maintenance and wear in rotating machinery, making it ideal for applications requiring high reliability and minimal downtime. Slip rings, while more traditional, provide continuous electrical connection with simpler installation and cost-effectiveness in low-speed or less demanding environments. Selecting the right technology depends on factors such as operational speed, power requirements, environmental conditions, and maintenance capabilities.

Future Trends in Power Transfer Solutions

Wireless power transfer technology advances rapidly with innovations like resonant inductive coupling and ultrasonic energy transfer, offering contactless, maintenance-free power for electric vehicles and industrial automation. Slip rings, traditionally used for continuous electrical transmission in rotating machinery, face limitations due to wear and signal degradation but are being enhanced with high-quality materials and integrated sensors for predictive maintenance. Future trends emphasize hybrid systems combining wireless transfer's flexibility with slip rings' reliability, promoting more efficient, durable, and scalable power transfer solutions in smart grids and rotating equipment.

Wireless power transfer Infographic

libterm.com

libterm.com