Open channels are natural or artificial waterways designed for the flow of water with a free surface exposed to the atmosphere. They are essential for irrigation, drainage, flood control, and water supply systems, allowing efficient movement of water using gravity. Explore the rest of this article to understand the types, design principles, and applications of open channels for your engineering projects.

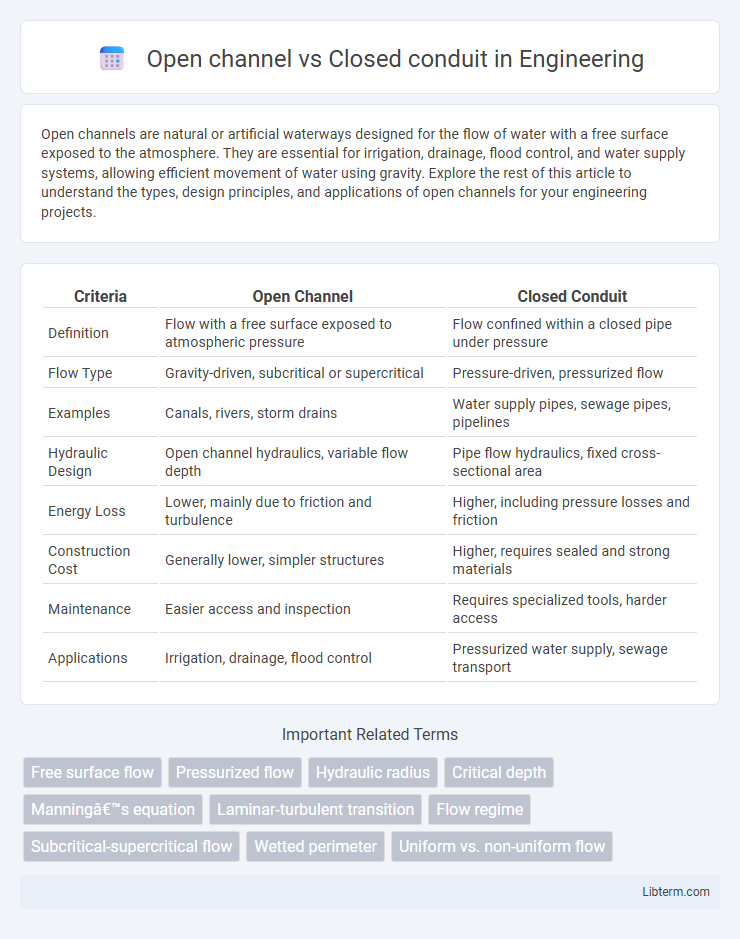

Table of Comparison

| Criteria | Open Channel | Closed Conduit |

|---|---|---|

| Definition | Flow with a free surface exposed to atmospheric pressure | Flow confined within a closed pipe under pressure |

| Flow Type | Gravity-driven, subcritical or supercritical | Pressure-driven, pressurized flow |

| Examples | Canals, rivers, storm drains | Water supply pipes, sewage pipes, pipelines |

| Hydraulic Design | Open channel hydraulics, variable flow depth | Pipe flow hydraulics, fixed cross-sectional area |

| Energy Loss | Lower, mainly due to friction and turbulence | Higher, including pressure losses and friction |

| Construction Cost | Generally lower, simpler structures | Higher, requires sealed and strong materials |

| Maintenance | Easier access and inspection | Requires specialized tools, harder access |

| Applications | Irrigation, drainage, flood control | Pressurized water supply, sewage transport |

Definition of Open Channel and Closed Conduit

An open channel is a water conveyance system with a free surface exposed to atmospheric pressure, such as rivers, canals, and natural streams, where flow occurs under gravity. A closed conduit refers to a pipe or tunnel completely filled with fluid, operating under pressure without a free surface, commonly used in water supply, sewage, and industrial applications. The key distinction lies in the presence of an open free surface in open channels versus fully enclosed flow in closed conduits.

Key Differences Between Open Channel and Closed Conduit

Open channels transport fluid with a free surface exposed to atmospheric pressure, typically used in irrigation, drainage, or natural streams. Closed conduits, like pipes, transport fluid completely enclosed, allowing pressurized flow ideal for water supply and sewage systems. Key differences include flow types--open channels exhibit gravity-driven flow with varying depths, while closed conduits often maintain pressurized, steady flow without a free surface.

Flow Characteristics in Open Channels

Open channels exhibit free-surface flow where the water surface is exposed to atmospheric pressure, causing flow characteristics to vary with channel slope, roughness, and flow depth. Flow in open channels is typically subcritical or supercritical, influenced by factors like velocity, flow area, and gravitational acceleration, and is described by parameters such as Froude number. Unlike closed conduits, open channel flow is subject to complex variations in depth and velocity profiles, with energy losses due to turbulence and surface waves affecting hydraulic efficiency.

Flow Characteristics in Closed Conduits

Flow in closed conduits typically exhibits pressurized, full-flow conditions with a constant cross-sectional area, allowing for higher velocities and controlled discharge rates compared to open channels. The head loss due to friction and minor losses in fittings significantly influences the flow behavior, governed by the Darcy-Weisbach or Hazen-Williams equations. Unlike open channels, closed conduits maintain a sealed environment, preventing air entrainment and enabling accurate pressure and flow calculations essential for hydraulic system design.

Common Applications of Open Channels

Open channels are commonly used in irrigation systems, stormwater drainage, and natural waterways to efficiently convey water by gravity flow. These channels are ideal for agricultural fields, canals, and rivers where water surface flow is exposed to the atmosphere. Their design accommodates variable flow rates and sediment transport, making them suitable for flood control and environmental management applications.

Typical Uses of Closed Conduits

Closed conduits are typically used in environments requiring controlled fluid transport, such as in water supply systems, sewage pipelines, and chemical processing plants. These conduits efficiently handle pressurized flows, minimizing leakage and contamination risks compared to open channels. Industrial facilities and municipal infrastructures rely on closed conduits for reliable, high-pressure transport and protection against environmental factors.

Design Considerations for Open Channels

Design considerations for open channels emphasize hydraulic properties such as flow rate, channel slope, and roughness coefficient to ensure efficient water conveyance and prevent erosion. Proper channel shape selection, like trapezoidal or rectangular sections, optimizes flow capacity and sediment transport. Structural stability measures, including bank protection and appropriate lining materials, are critical to maintaining channel integrity under varying flow conditions.

Engineering Factors in Closed Conduit Design

Closed conduit design in engineering prioritizes factors such as pressure management, material strength, and flow velocity to ensure structural integrity and efficient fluid transport. Hydraulic calculations focus on minimizing head loss and turbulence by optimizing conduit diameter, roughness, and slope, while also considering the potential for surge pressures and thermal expansion. Proper sealing, joint design, and corrosion resistance are critical to maintaining durability and preventing leakage in closed systems.

Advantages and Disadvantages of Each System

Open channels offer easy inspection, maintenance, and lower construction costs but are prone to contamination, evaporation, and limited pressure control. Closed conduits provide efficient flow under pressure, reduce contamination risks, and allow better control of fluid velocity but involve higher installation expenses and complex maintenance. Selecting the appropriate system depends on factors like terrain, fluid type, and project budget.

Choosing Between Open Channel and Closed Conduit Systems

Choosing between open channel and closed conduit systems depends on flow requirements, environmental factors, and maintenance considerations. Open channels are suited for gravity-driven, low-pressure flows with ease of access for inspection and are cost-effective for large volumes. Closed conduits excel in pressurized, high-velocity applications with controlled environments, minimizing contamination and evaporation losses.

Open channel Infographic

libterm.com

libterm.com