An open loop system operates without feedback, meaning it does not adjust its output based on changes in the environment or system performance. This type of control is simpler but can lead to inaccuracies when unexpected disturbances occur. Discover how understanding open loop systems can enhance your grasp of control mechanisms by exploring the rest of the article.

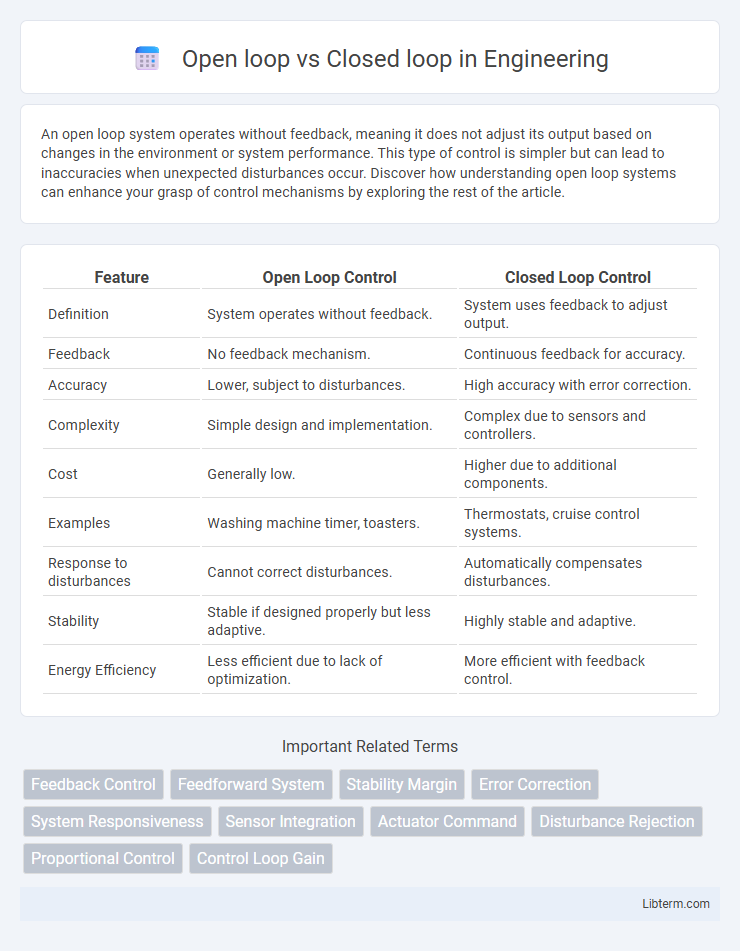

Table of Comparison

| Feature | Open Loop Control | Closed Loop Control |

|---|---|---|

| Definition | System operates without feedback. | System uses feedback to adjust output. |

| Feedback | No feedback mechanism. | Continuous feedback for accuracy. |

| Accuracy | Lower, subject to disturbances. | High accuracy with error correction. |

| Complexity | Simple design and implementation. | Complex due to sensors and controllers. |

| Cost | Generally low. | Higher due to additional components. |

| Examples | Washing machine timer, toasters. | Thermostats, cruise control systems. |

| Response to disturbances | Cannot correct disturbances. | Automatically compensates disturbances. |

| Stability | Stable if designed properly but less adaptive. | Highly stable and adaptive. |

| Energy Efficiency | Less efficient due to lack of optimization. | More efficient with feedback control. |

Introduction to Open Loop and Closed Loop Systems

Open loop systems operate without feedback, where the output is generated based solely on input commands, making them simple but less accurate. Closed loop systems utilize feedback mechanisms to continuously adjust output, enhancing precision and stability in dynamic environments. These fundamental differences influence their applications in automation, control engineering, and process management.

Defining Open Loop Systems

Open loop systems operate without feedback, executing predefined instructions regardless of output results, making them simpler and more cost-effective in applications where feedback is unnecessary. These systems rely solely on initial input signals to perform tasks, such as basic heating elements or timers in appliances. The lack of real-time response limits their accuracy and adaptability compared to closed loop systems, which continuously monitor and adjust based on output feedback.

Defining Closed Loop Systems

Closed loop systems continuously monitor output feedback to self-regulate and maintain desired performance levels, enhancing accuracy and stability compared to open loop systems that operate without feedback. These systems automatically adjust inputs based on real-time sensor data, minimizing errors caused by disturbances or changes in the environment. Examples include thermostats, autopilot systems, and industrial process controls where precise regulation is critical.

Key Differences Between Open Loop and Closed Loop

Open loop systems operate without feedback, relying solely on predefined inputs to produce outputs, whereas closed loop systems continuously monitor output and adjust inputs based on feedback to maintain desired performance. Open loop controls are simpler, cost-effective, and faster but less accurate, while closed loop controls offer higher precision, stability, and adaptability at the cost of complexity and increased expense. Key differences include dependence on feedback, accuracy, system stability, and response to disturbances.

Advantages of Open Loop Systems

Open loop systems offer simplicity and low cost due to their straightforward design without feedback mechanisms, enabling faster response times and easier implementation in applications where precision control is not critical. Their reliability is enhanced by fewer components that might fail, making them suitable for environments with stable and predictable conditions. Open loop systems also consume less power, making them ideal for energy-efficient operations in devices like washing machines and irrigation systems.

Advantages of Closed Loop Systems

Closed loop systems offer enhanced accuracy by continuously monitoring output and adjusting inputs based on feedback, reducing errors and improving performance. These systems provide better stability and adaptability in dynamic environments, ensuring consistent results despite external disturbances. Their self-correcting nature also minimizes system drift and maintenance needs, leading to increased reliability and efficiency.

Disadvantages of Open Loop Systems

Open loop systems suffer from a lack of feedback control, making them unable to correct errors or adapt to disturbances, which leads to decreased accuracy and reliability. They are vulnerable to performance degradation due to environmental changes or system parameter variations, compromising consistent operation. The absence of real-time monitoring increases the risk of system failure, limiting their effectiveness in complex or dynamic applications.

Disadvantages of Closed Loop Systems

Closed loop systems often face increased complexity due to continuous feedback processing, which can lead to slower response times and higher costs in implementation and maintenance. These systems are susceptible to feedback noise and inaccuracies, potentially causing instability or oscillations in the output. Furthermore, malfunctioning sensors or controllers can degrade system performance significantly, making troubleshooting and calibration more challenging compared to open loop systems.

Real-World Applications of Open Loop vs Closed Loop

Open loop systems are widely used in applications such as washing machines and irrigation systems where input actions are predefined and the system operates without feedback, providing simplicity and cost-effectiveness. Closed loop systems are essential in autonomous vehicles and industrial robots, utilizing sensor feedback to continuously adjust operations for precision and adaptability in dynamic environments. These control strategies optimize performance by balancing complexity, responsiveness, and application-specific requirements.

Choosing the Right System for Your Needs

Selecting between open loop and closed loop control systems depends on the required precision and feedback complexity. Open loop systems offer simplicity and cost-effectiveness but lack error correction, making them suitable for stable, predictable environments. Closed loop systems utilize sensors and feedback to continuously adjust performance, providing higher accuracy and adaptability for dynamic or critical processes.

Open loop Infographic

libterm.com

libterm.com