Heat exchangers transfer thermal energy efficiently between fluids without mixing them, critical in industries like HVAC, power generation, and chemical processing. Understanding the types, such as shell-and-tube or plate heat exchangers, helps optimize your system's performance and energy savings. Explore the rest of the article to learn how to select and maintain the best heat exchanger for your needs.

Table of Comparison

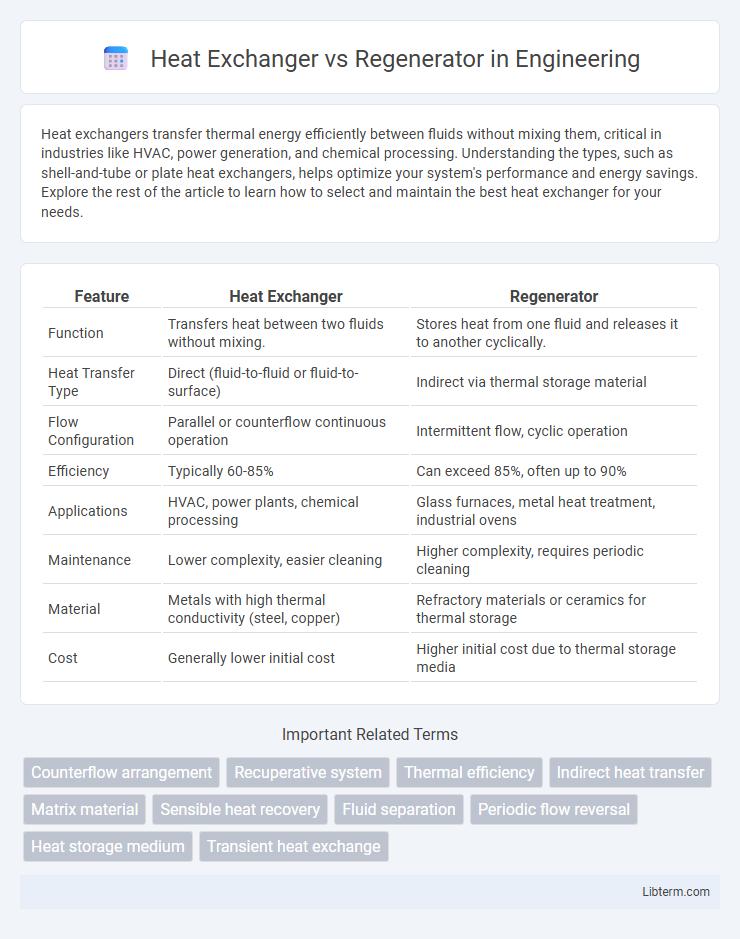

| Feature | Heat Exchanger | Regenerator |

|---|---|---|

| Function | Transfers heat between two fluids without mixing. | Stores heat from one fluid and releases it to another cyclically. |

| Heat Transfer Type | Direct (fluid-to-fluid or fluid-to-surface) | Indirect via thermal storage material |

| Flow Configuration | Parallel or counterflow continuous operation | Intermittent flow, cyclic operation |

| Efficiency | Typically 60-85% | Can exceed 85%, often up to 90% |

| Applications | HVAC, power plants, chemical processing | Glass furnaces, metal heat treatment, industrial ovens |

| Maintenance | Lower complexity, easier cleaning | Higher complexity, requires periodic cleaning |

| Material | Metals with high thermal conductivity (steel, copper) | Refractory materials or ceramics for thermal storage |

| Cost | Generally lower initial cost | Higher initial cost due to thermal storage media |

Introduction to Heat Exchangers and Regenerators

Heat exchangers and regenerators are fundamental devices in thermal systems designed to transfer heat between fluids. Heat exchangers typically use separate channels to prevent fluid mixing while maximizing heat transfer efficiency. Regenerators store thermal energy temporarily in a matrix material, releasing it to the fluid during cyclic operations, making them ideal for processes involving intermittent heat recovery.

Core Principles: How Heat Exchangers Work

Heat exchangers transfer thermal energy between two or more fluids without mixing them, using conductive and convective heat transfer principles across solid surfaces or membranes. They rely on temperature gradients and flow arrangements--such as counterflow, parallel flow, or crossflow--to maximize heat transfer efficiency. In contrast, regenerators temporarily store heat from a hot fluid in a thermal mass and release it to a cold fluid cyclically, optimizing energy recovery in intermittent processes.

Understanding the Functionality of Regenerators

Regenerators capture and store thermal energy from hot fluid streams, releasing it to incoming cold streams, enhancing energy efficiency in cyclic processes. Unlike heat exchangers that transfer heat directly between two fluids, regenerators utilize a thermal storage medium that cyclically absorbs and releases heat. This functionality allows regenerators to recover and reuse heat effectively in applications such as gas turbines and industrial heating systems.

Key Differences Between Heat Exchangers and Regenerators

Heat exchangers transfer heat between two or more fluids without mixing them, typically using separate channels to maintain continuous flow, while regenerators temporarily store thermal energy in a medium before transferring it to another fluid, allowing intermittent heat exchange. Heat exchangers are more efficient for steady-state operations, whereas regenerators are suitable for cyclic processes with high temperature differences. The primary distinction lies in the thermal storage capacity of regenerators, which enables energy recovery and reduced fuel consumption in applications like gas turbines and furnaces.

Applications of Heat Exchangers in Industry

Heat exchangers are critical in industries such as chemical processing, power generation, and HVAC for transferring heat between fluids efficiently, optimizing energy consumption and operational costs. Common applications include cooling engine oil, condensing steam in power plants, and heating chemical reactors, where continuous and controlled heat transfer is essential. Unlike regenerators, heat exchangers provide steady-state heat exchange without thermal storage, making them ideal for processes requiring consistent temperature regulation.

Industrial Uses of Regenerators

Regenerators are widely used in industries such as steel manufacturing and power plants to recover waste heat from flue gases and improve energy efficiency by cyclically storing and releasing heat. Unlike heat exchangers, which provide continuous heat transfer, regenerators are especially effective in high-temperature processes requiring intermittent heat storage and regeneration, leading to significant fuel savings. Industrial applications benefit from regenerators in processes like glass melting, cement production, and gas turbines, where they reduce operational costs and carbon emissions by recycling thermal energy.

Efficiency Comparison: Heat Exchanger vs Regenerator

Heat exchangers typically achieve efficiency levels between 70% and 90% by transferring heat between fluids without mixing them, relying on conduction and convection. Regenerators can reach higher efficiencies, often exceeding 90%, by temporarily storing heat in a solid medium and releasing it back to the fluid, which reduces energy losses in cyclic processes. The choice depends on factors like operating temperature ranges, process dynamics, and the specific heat recovery requirements of industrial applications.

Maintenance and Lifespan Considerations

Heat exchangers generally require less frequent maintenance due to their simpler design, with periodic cleaning to prevent fouling and corrosion extending their lifespan up to 20 years or more. Regenerators, with their rotating or fixed matrix elements, demand more rigorous inspection and maintenance to address potential wear, leakage, and thermal stress, which can limit their operational life to around 10-15 years if not properly maintained. Selecting between the two requires evaluating the maintenance complexity and expected lifespan in relation to the specific heat recovery application.

Cost Analysis: Initial Investment and Operating Expenses

Heat exchangers typically require a lower initial investment compared to regenerators due to simpler design and manufacturing processes, making them cost-effective for many industrial applications. Operating expenses for heat exchangers tend to be lower because they have fewer moving parts and reduced maintenance requirements, while regenerators often incur higher costs from frequent cleaning and potential pressure drops. Long-term cost analysis shows heat exchangers offer better overall economic efficiency in continuous operations, whereas regenerators may justify higher initial and operating costs in cyclic or high-temperature recovery scenarios.

Choosing the Right Solution: Heat Exchanger or Regenerator?

Selecting between a heat exchanger and a regenerator depends on factors like thermal efficiency, application type, and operating conditions. Heat exchangers provide continuous heat transfer between fluids, ideal for steady-state processes with moderate temperature differences, while regenerators store thermal energy cyclically, offering higher efficiency in applications with fluctuating temperatures or intermittent operation. Evaluating the specific heat recovery needs, maintenance requirements, and system cost helps determine the most effective solution for energy conservation and system performance.

Heat Exchanger Infographic

libterm.com

libterm.com