Erosion is the natural process where soil, rock, or other surface materials are worn away and transported by wind, water, or ice. This phenomenon affects landscapes, agriculture, and infrastructure, leading to significant environmental and economic challenges. Discover more about how you can protect your land and reduce erosion risks in the rest of this article.

Table of Comparison

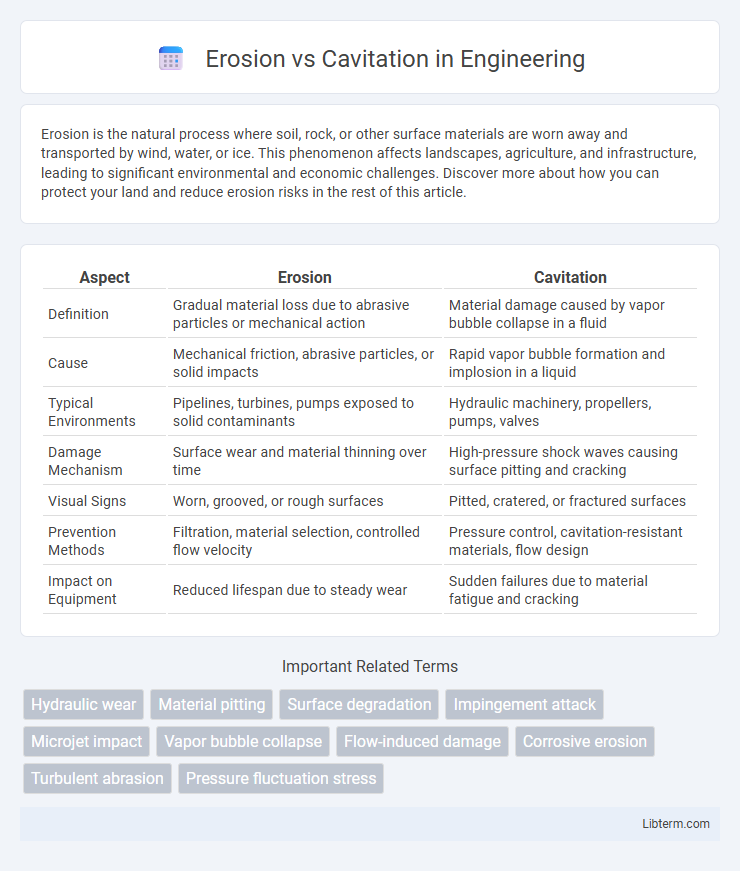

| Aspect | Erosion | Cavitation |

|---|---|---|

| Definition | Gradual material loss due to abrasive particles or mechanical action | Material damage caused by vapor bubble collapse in a fluid |

| Cause | Mechanical friction, abrasive particles, or solid impacts | Rapid vapor bubble formation and implosion in a liquid |

| Typical Environments | Pipelines, turbines, pumps exposed to solid contaminants | Hydraulic machinery, propellers, pumps, valves |

| Damage Mechanism | Surface wear and material thinning over time | High-pressure shock waves causing surface pitting and cracking |

| Visual Signs | Worn, grooved, or rough surfaces | Pitted, cratered, or fractured surfaces |

| Prevention Methods | Filtration, material selection, controlled flow velocity | Pressure control, cavitation-resistant materials, flow design |

| Impact on Equipment | Reduced lifespan due to steady wear | Sudden failures due to material fatigue and cracking |

Introduction to Erosion and Cavitation

Erosion and cavitation are significant physical phenomena that cause material degradation in fluid environments, impacting the longevity and performance of hydraulic machinery and pipelines. Erosion results from the mechanical wear caused by solid particles or fluid flow impacting surfaces, leading to gradual material loss. Cavitation involves the formation and violent collapse of vapor bubbles in a liquid, generating shock waves that damage surfaces at a microscopic level.

Defining Erosion: Causes and Effects

Erosion is the gradual removal of material from a solid surface caused by mechanical action such as abrasion, friction, or impact from particles in a fluid stream. Common causes include flowing water with sediments, wind carrying dust, and chemical reactions that weaken material integrity. The effects of erosion include surface loss, reduced structural strength, and increased maintenance costs across industries like pipelines, turbines, and hydraulic machinery.

What is Cavitation? Key Characteristics

Cavitation is the formation and rapid collapse of vapor-filled bubbles in a liquid caused by pressure fluctuations, often occurring in pumps, propellers, and turbines. Key characteristics include intense localized pressure surges, noise, vibration, and potential damage to surfaces through pitting and material erosion. Unlike general erosion, cavitation damage is distinguished by its unique bubble dynamics and sudden, high-energy impacts on metal surfaces.

Physical Mechanisms Behind Erosion

Erosion results from the mechanical wear caused by solid particles or fluid droplets impacting a surface, leading to material loss through processes like abrasion, adhesion, and fatigue. Cavitation involves the formation and collapse of vapor bubbles in a liquid near a surface, generating intense shock waves and microjets that cause localized pitting and surface damage. Both mechanisms induce material degradation but differ fundamentally in their physical origin: erosion relies on direct mechanical interaction, while cavitation stems from dynamic vapor phase changes and subsequent implosion effects.

How Cavitation Occurs: The Science Explained

Cavitation occurs when rapid changes in pressure within a liquid cause the formation and collapse of vapor bubbles near a surface, leading to intense shock waves that damage materials. This phenomenon typically arises in pumps, propellers, and turbines where local pressure drops below the liquid's vapor pressure, resulting in bubble nucleation and implosion. Understanding the fluid dynamics and pressure variations is crucial to predicting cavitation and mitigating its destructive effects.

Erosion vs Cavitation: Main Differences

Erosion involves gradual material loss due to mechanical wear or chemical reactions, whereas cavitation results from the formation and collapse of vapor bubbles causing localized shock waves. Erosion typically affects surfaces exposed to solid particle impact or fluid abrasion, while cavitation damage occurs primarily in hydraulic systems and pumps where pressure fluctuations create vapor cavities. The main difference lies in erosion being a slower, abrasive process, contrasted with cavitation causing sudden, pitting damage through intense micro-impacts.

Factors Influencing Erosion and Cavitation

Erosion and cavitation processes are primarily influenced by fluid velocity, pressure variations, and the physical properties of the material surface. High fluid velocity increases particle impact energy, accelerating erosion, while rapid pressure changes cause vapor bubble formation and collapse, driving cavitation damage. Material hardness, surface roughness, and temperature also significantly affect the severity and rate of both erosion and cavitation.

Common Industries Impacted by Erosion and Cavitation

Erosion and cavitation significantly affect industries such as marine engineering, power generation, and chemical processing by damaging pump impellers, turbine blades, and pipe surfaces. The oil and gas sector experiences frequent maintenance issues due to erosion caused by solid particle abrasion and cavitation induced by pressure fluctuations in pipelines. Water treatment and hydroelectric plants also face reduced equipment lifespan and operational efficiency because of the combined effects of erosive wear and cavitation damage.

Prevention and Mitigation Strategies

Erosion prevention strategies include selecting corrosion-resistant materials such as stainless steel or ceramic coatings and implementing flow control measures to reduce velocity and turbulence that contribute to material wear. Cavitation mitigation involves designing pump impellers and propellers to minimize pressure drops, maintaining optimal operating conditions to avoid vapor bubble formation, and installing air release valves or anti-cavitation devices. Regular inspection and maintenance schedules are critical for early detection and repair, ensuring long-term protection against both erosion and cavitation damage.

Conclusion: Comparing Erosion and Cavitation

Erosion primarily results from the mechanical wear caused by solid particles impacting surfaces, while cavitation is driven by vapor bubble formation and collapse, inducing localized high-pressure shock waves. Both phenomena lead to material degradation but differ in their underlying mechanisms and damage patterns, with cavitation often causing more aggressive and pitting corrosion-like effects. Understanding these distinctions is critical for implementing targeted mitigation strategies in fluid handling and hydraulic machinery.

Erosion Infographic

libterm.com

libterm.com