A cam profile defines the specific shape and contour of a cam, crucial for controlling the motion and timing in mechanical systems like engines and automation equipment. Precise cam profiles optimize performance by converting rotary motion into desired linear or oscillating movement, enhancing efficiency and durability. Explore the detailed insights in the rest of this article to understand how the right cam profile can improve your mechanical design.

Table of Comparison

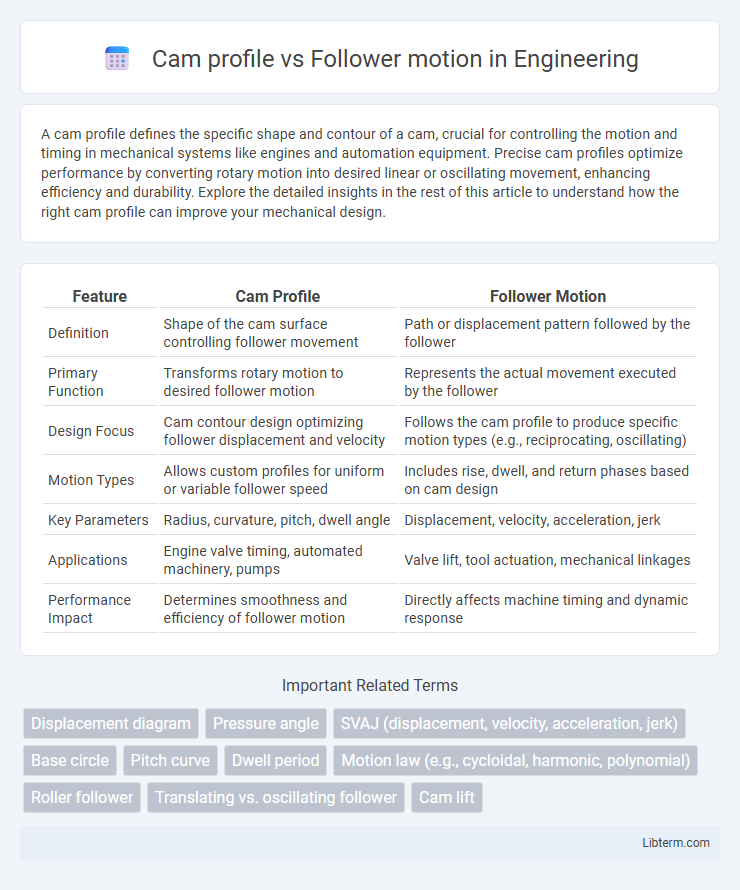

| Feature | Cam Profile | Follower Motion |

|---|---|---|

| Definition | Shape of the cam surface controlling follower movement | Path or displacement pattern followed by the follower |

| Primary Function | Transforms rotary motion to desired follower motion | Represents the actual movement executed by the follower |

| Design Focus | Cam contour design optimizing follower displacement and velocity | Follows the cam profile to produce specific motion types (e.g., reciprocating, oscillating) |

| Motion Types | Allows custom profiles for uniform or variable follower speed | Includes rise, dwell, and return phases based on cam design |

| Key Parameters | Radius, curvature, pitch, dwell angle | Displacement, velocity, acceleration, jerk |

| Applications | Engine valve timing, automated machinery, pumps | Valve lift, tool actuation, mechanical linkages |

| Performance Impact | Determines smoothness and efficiency of follower motion | Directly affects machine timing and dynamic response |

Introduction to Cam Profiles and Follower Motion

Cam profiles define the precise geometric contour of a cam, which directly influences the motion characteristics of the follower. Follower motion describes how the follower responds to the cam profile's shape, converting rotary motion into specific linear or oscillatory movements. Understanding the interaction between cam profiles and follower motion is crucial for optimizing machine mechanisms in automotive, manufacturing, and automation industries.

Understanding Cam Profiles: Types and Functions

Cam profiles play a crucial role in converting rotary motion into predetermined follower motion, with common types including plate, cylindrical, and face cams. Each cam profile is designed to generate specific follower movements such as uniform, harmonic, or cycloidal motions, optimizing mechanical efficiency and performance. Understanding the functions and applications of various cam profiles helps engineers select the appropriate cam-follower system for precise motion control in machinery.

Basics of Follower Motion in Mechanisms

Follower motion in mechanisms refers to the movement of a component driven by the cam's profile, transforming rotary input into precise linear or oscillatory output. The follower's displacement, velocity, and acceleration are directly determined by the cam profile shape, which is designed to achieve specific motion requirements. Understanding the basics of follower motion involves analyzing the follower's path, types of motion (such as uniform, harmonic), and the impact of cam geometry on dynamic performance and mechanical efficiency.

Key Differences Between Cam Profiles and Follower Motion

Cam profiles dictate the precise shape and contour of the cam, which determines the motion path followed by the cam follower. Follower motion refers to the actual movement pattern of the follower as it interacts with the cam profile, including rise, dwell, and return phases. Key differences include that cam profiles are static geometrical designs, while follower motion is dynamic movement resulting from the cam's rotation and profile geometry.

Design Considerations for Selecting Cam Profiles

Selecting cam profiles requires analyzing the motion requirements of the follower, such as dwell, rise, and return phases, to ensure smooth and precise operation. Design considerations include minimizing acceleration and jerk to reduce wear and noise, optimizing contact stress for durability, and accommodating the follower type and load conditions. Material selection, manufacturing tolerances, and lubrication also play critical roles in achieving reliable cam-follower motion performance.

Types of Follower Motion: Uniform, Harmonic, Cycloidal, and Polynomial

Cam profiles generate specific follower motions characterized by the contour design, influencing the follower's displacement, velocity, and acceleration. Types of follower motion include Uniform motion, where the follower moves at a constant velocity; Harmonic motion, following a sinusoidal displacement yielding smooth acceleration; Cycloidal motion, providing minimal acceleration peaks ideal for reducing vibration; and Polynomial motion, using algebraic expressions for customizable displacement profiles balancing speed and smoothness. Each type optimizes performance in cam-follower systems by tailoring motion to application demands such as precision and mechanical stress reduction.

Influence of Cam Profile on Follower Motion Characteristics

The cam profile significantly determines the follower motion characteristics by controlling displacement, velocity, and acceleration patterns, which directly influence the system's dynamic response and wear. A well-designed cam profile minimizes undesirable vibrations and ensures smooth follower motion, improving mechanical efficiency and reducing noise. Precise tailoring of cam geometry to application-specific requirements enhances performance by optimizing follower trajectory and load distribution.

Applications of Cam Profile and Follower Motion in Industry

Cam profiles and follower motions are critical in automation, packaging, and automotive industries, where precise motion control enhances machine efficiency and product quality. Applications include controlling valve timings in engines, converting rotary motion to linear motion in packaging machines, and synchronizing robotic arm movements in assembly lines. Optimized cam-follower designs improve durability, reduce wear, and enable complex motion patterns essential for industrial machinery performance.

Performance Analysis: Efficiency and Wear in Cam-Follower Systems

Cam profile design significantly impacts the performance efficiency and wear characteristics in cam-follower systems, with optimized profiles reducing frictional losses and energy consumption. A smooth, tailored cam profile minimizes abrupt acceleration changes, lowering dynamic loads and resultant wear on the follower and cam surfaces. Performance analysis reveals that precise profile optimization extends component lifespan and enhances overall system reliability by balancing efficiency with mechanical durability.

Choosing the Right Cam Profile and Follower Motion for Your Application

Selecting the appropriate cam profile and follower motion is crucial for optimizing performance and longevity in mechanical systems. Different cam profiles such as circular, elliptical, or pear-shaped directly influence the follower's displacement, velocity, and acceleration, impacting smoothness and wear. Matching the follower motion type--like oscillating, translating, or reciprocating--to your application's load and speed requirements ensures precise control and efficient energy transfer.

Cam profile Infographic

libterm.com

libterm.com