A pump is a mechanical device designed to move fluids or gases from one place to another, essential in various industries including agriculture, manufacturing, and water treatment. Understanding the different types of pumps, such as centrifugal, positive displacement, and diaphragm pumps, helps you choose the right solution for your specific needs. Explore the rest of the article to discover how pumps work and their diverse applications.

Table of Comparison

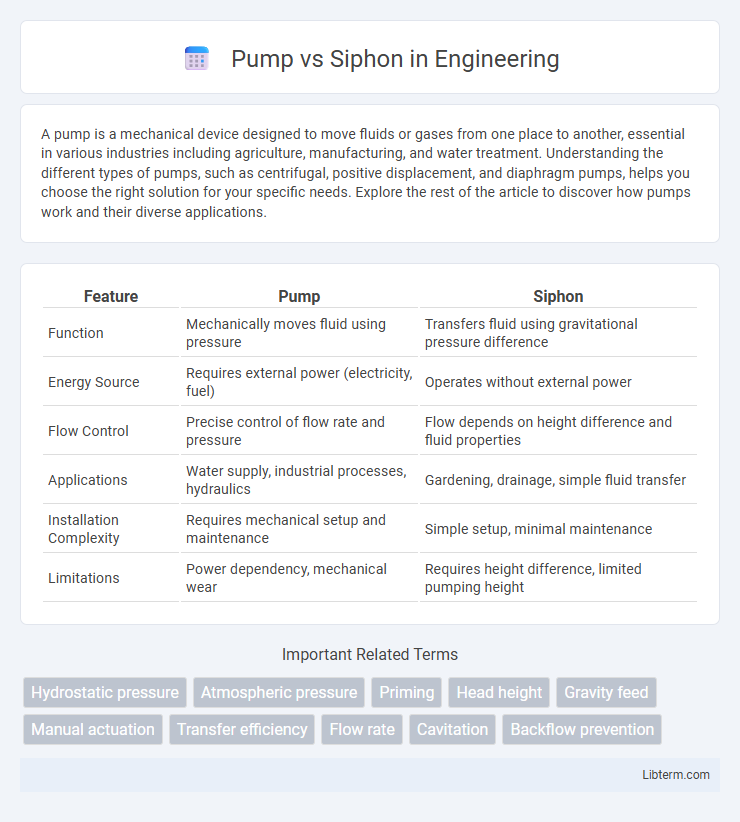

| Feature | Pump | Siphon |

|---|---|---|

| Function | Mechanically moves fluid using pressure | Transfers fluid using gravitational pressure difference |

| Energy Source | Requires external power (electricity, fuel) | Operates without external power |

| Flow Control | Precise control of flow rate and pressure | Flow depends on height difference and fluid properties |

| Applications | Water supply, industrial processes, hydraulics | Gardening, drainage, simple fluid transfer |

| Installation Complexity | Requires mechanical setup and maintenance | Simple setup, minimal maintenance |

| Limitations | Power dependency, mechanical wear | Requires height difference, limited pumping height |

Introduction to Pumps and Siphons

Pumps and siphons serve distinct roles in fluid transfer, with pumps actively moving liquids using mechanical energy, while siphons rely on gravitational force to transfer fluids over barriers. Pumps vary from positive displacement types, which move fluid by trapping a fixed volume, to dynamic pumps that impart velocity to fluids for flow. Siphons operate by creating a pressure differential, allowing liquid to flow from a higher elevation to a lower elevation without external power.

How Pumps Work: Mechanisms and Types

Pumps operate by transferring fluids through mechanical action using various mechanisms such as positive displacement or centrifugal force. Positive displacement pumps move fluid by trapping a fixed amount and forcing it through the discharge, ideal for precise flow control. Centrifugal pumps utilize a rotating impeller to increase fluid velocity and pressure, making them efficient for high flow applications.

Understanding Siphons: Principles and Applications

Siphons operate on the principle of atmospheric pressure and gravity, allowing liquid to flow from a higher elevation to a lower one through a tube without mechanical assistance. Unlike pumps, siphons do not require external energy, making them efficient for transferring fluids over obstacles or between containers of varying heights. Common applications include irrigation, fuel transfer, and aquarium water changes, where siphon setup enables continuous fluid movement using natural forces.

Key Differences Between Pumps and Siphons

Pumps use mechanical or electrical energy to move fluids against gravity, generating pressure to transfer liquids efficiently over various distances and heights. Siphons rely on atmospheric pressure and gravity by creating a continuous flow from a higher to a lower elevation without external energy input. The key differences lie in energy usage--pumps require power sources, while siphons operate passively--and in application versatility, with pumps handling pressurized transfers and siphons limited to gravity-driven flow.

Advantages of Using Pump Systems

Pump systems provide consistent fluid transfer with controlled flow rates, making them ideal for precise applications in industrial and agricultural settings. They can handle a wide range of fluid viscosities and pressures, offering flexibility that siphons lack. Pumps also allow for vertical lifting of liquids, overcoming gravity constraints inherent in siphon systems.

Benefits and Limitations of Siphon Systems

Siphon systems offer energy-efficient fluid transfer by utilizing gravitational force, eliminating the need for external power sources and reducing operational costs. Their design simplicity results in low maintenance and long-term durability, but siphons require a continuous fluid column and precise installation to maintain flow and prevent airlocks. Limitations include restrictions on height difference between source and destination and susceptibility to contamination if the fluid path is interrupted.

Common Uses of Pumps vs Siphons

Pumps are commonly used in applications requiring consistent and controlled fluid transfer, such as water supply systems, irrigation, and industrial processes. Siphons are typically employed for simple fluid transfer tasks where gravity can assist, such as draining aquariums, emptying fuel tanks, or transferring liquids between containers without mechanical assistance. The choice between pumps and siphons depends on factors like the need for pressure, flow rate control, and energy availability.

Energy Efficiency Comparison: Pump vs Siphon

Pumps consume electrical or mechanical energy to move fluids actively, resulting in higher energy expenditure compared to siphons, which rely on gravitational potential and atmospheric pressure to transfer liquids passively. Siphons operate without external power, making them more energy-efficient for applications where fluid transfer over a vertical distance is feasible without obstacles. However, pumps provide consistent flow rates and pressure regardless of elevation changes, which can justify their energy use in complex or high-demand systems.

Choosing the Right Method for Your Application

Choosing between a pump and a siphon depends largely on the specific needs of your application, such as flow rate, distance, and elevation changes. Pumps offer precise control and can move fluids uphill or over long distances, making them ideal for industrial or high-volume tasks. Siphons require gravity and a continuous flow path, providing an energy-efficient solution for transferring liquids over short distances or below the source level.

Conclusion: Pump or Siphon—Which Is Best?

Choosing between a pump and a siphon depends on the specific application, fluid properties, and energy availability. Pumps offer controlled, consistent flow with the ability to move fluids uphill or across long distances, making them ideal for industrial and high-demand scenarios. Siphons rely on gravity and atmospheric pressure, providing a cost-effective and energy-efficient solution for transferring liquids over short vertical drops without power requirements.

Pump Infographic

libterm.com

libterm.com