Globe valves regulate fluid flow through a movable disk and a stationary ring seat, providing precise throttling and shutoff capabilities in pipelines. They are widely used in applications requiring flow control and frequent operation, such as cooling water systems and fuel oil systems. Explore the rest of the article to understand how a globe valve can enhance your system's performance and efficiency.

Table of Comparison

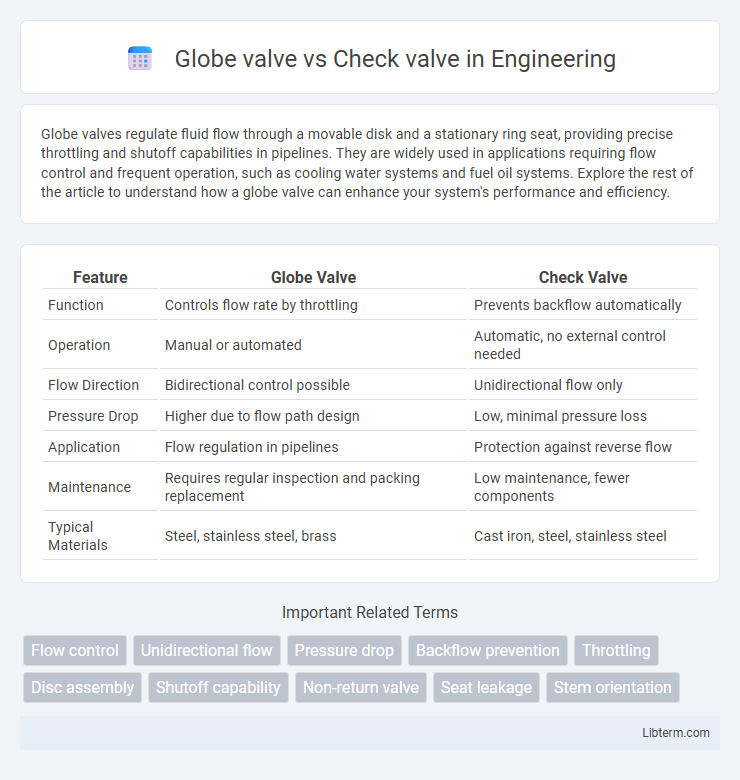

| Feature | Globe Valve | Check Valve |

|---|---|---|

| Function | Controls flow rate by throttling | Prevents backflow automatically |

| Operation | Manual or automated | Automatic, no external control needed |

| Flow Direction | Bidirectional control possible | Unidirectional flow only |

| Pressure Drop | Higher due to flow path design | Low, minimal pressure loss |

| Application | Flow regulation in pipelines | Protection against reverse flow |

| Maintenance | Requires regular inspection and packing replacement | Low maintenance, fewer components |

| Typical Materials | Steel, stainless steel, brass | Cast iron, steel, stainless steel |

Introduction to Globe Valves and Check Valves

Globe valves regulate fluid flow through a movable disk and a stationary ring seat, offering precise throttling capabilities for various industrial applications. Check valves prevent backflow by allowing fluid to flow in only one direction, protecting pumps and pipelines from damage. Both valves play crucial roles in fluid control systems but serve distinctly different operational purposes.

Key Differences Between Globe Valves and Check Valves

Globe valves offer precise flow control with a linear motion disk designed to regulate fluid flow, whereas check valves provide automatic, one-way flow prevention without manual operation. Globe valves are manually operated, commonly used for throttling applications, and exhibit higher pressure drops compared to check valves, which rely on differential pressure for operation and prevent backflow to protect equipment. Material construction, sealing mechanisms, and typical applications further differentiate these valves, with globe valves favored in processes requiring frequent adjustment and check valves essential for system protection against reverse flow.

Design and Construction Comparison

Globe valves feature a linear motion design with a movable disk and a stationary ring seat, enabling precise flow control and throttling. Check valves utilize a one-way design with a hinged or spring-loaded disk that automatically prevents backflow, relying on pressure differentials for operation. The complex body and stem assembly of globe valves contrast with the simpler, streamlined construction of check valves designed primarily for flow direction control.

How Globe Valves Work

Globe valves regulate fluid flow by adjusting a movable disk against a stationary ring seat, allowing precise control over flow rate and pressure. The stem connected to the handwheel moves the disk up or down within the valve body, creating variable resistance to fluid passage. This design enables throttling and frequent operation, making globe valves ideal for applications requiring accurate flow control.

How Check Valves Function

Check valves function by allowing fluid flow in one direction while automatically preventing backflow, using a disc or ball that moves in response to pressure changes. When forward flow occurs, the valve opens as pressure pushes the disc away from the seat; during reverse flow or pressure drop, the disc returns to the seat, sealing the valve and preventing fluid from reversing. This one-way operation protects systems from damage caused by backflow in pipelines, pumps, and hydraulic systems.

Applications of Globe Valves

Globe valves are widely used in applications requiring precise flow regulation, such as in water treatment plants, chemical industries, and power generation systems. Their design allows for effective throttling control, making them ideal for isolating and controlling medium to high-pressure fluids. Globe valves are preferred in systems where accurate flow control and frequent operation are necessary, contrasting with check valves that primarily prevent backflow.

Applications of Check Valves

Check valves are primarily used in applications requiring unidirectional flow to prevent backflow and protect equipment such as pumps and compressors. Common industries include water and wastewater treatment, oil and gas pipelines, and chemical processing plants where maintaining flow integrity is critical. They are essential in HVAC systems, fuel systems, and steam lines to ensure system safety and efficiency.

Advantages and Disadvantages of Globe Valves

Globe valves offer precise flow control and excellent throttling capabilities, making them ideal for regulating fluid flow in pipelines and systems requiring frequent adjustment. Their design allows for quick shutoff and easy maintenance; however, globe valves create higher pressure drops due to their tortuous flow path, leading to reduced efficiency in some applications. Compared to check valves, which primarily prevent backflow, globe valves provide more versatile control but at the cost of increased energy consumption and potential wear on moving parts.

Pros and Cons of Check Valves

Check valves prevent backflow in piping systems, ensuring fluid flows in only one direction, which protects pumps and compressors from damage and maintains system efficiency. They require minimal maintenance and operate automatically without external control, but may cause pressure drop and water hammer if not properly selected or installed. Limited control over flow regulation and potential failure to close fully under low flow conditions are notable drawbacks compared to globe valves.

Choosing the Right Valve: Globe Valve vs Check Valve

Choosing the right valve depends on the function and flow control requirements within the system: globe valves excel at precise flow regulation and throttling, offering tight shut-off and modulating control in high-pressure environments. Check valves prevent backflow automatically, protecting pumps and compressors by allowing flow in only one direction without manual operation or control. Selecting between a globe valve and a check valve involves evaluating the need for flow adjustment versus backflow prevention to ensure optimal system efficiency and reliability.

Globe valve Infographic

libterm.com

libterm.com