Parallel-flow systems optimize heat exchange by directing fluids in the same direction, enhancing temperature uniformity and efficiency. This method is commonly applied in heat exchangers and cooling systems to prevent thermal stress and improve energy transfer. Discover how parallel-flow designs can benefit your applications in the detailed article ahead.

Table of Comparison

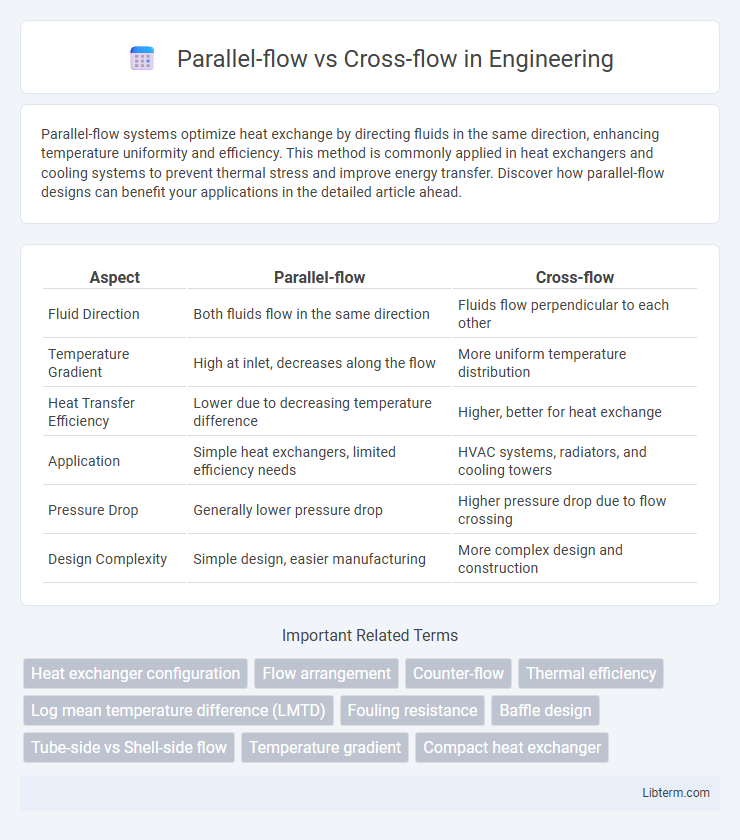

| Aspect | Parallel-flow | Cross-flow |

|---|---|---|

| Fluid Direction | Both fluids flow in the same direction | Fluids flow perpendicular to each other |

| Temperature Gradient | High at inlet, decreases along the flow | More uniform temperature distribution |

| Heat Transfer Efficiency | Lower due to decreasing temperature difference | Higher, better for heat exchange |

| Application | Simple heat exchangers, limited efficiency needs | HVAC systems, radiators, and cooling towers |

| Pressure Drop | Generally lower pressure drop | Higher pressure drop due to flow crossing |

| Design Complexity | Simple design, easier manufacturing | More complex design and construction |

Introduction to Parallel-flow and Cross-flow

Parallel-flow and cross-flow heat exchangers differ primarily in the direction of fluid movement relative to each other. In parallel-flow heat exchangers, both the hot and cold fluids move in the same direction, allowing heat transfer along a consistent temperature gradient, which can limit the maximum temperature exchange efficiency. Cross-flow heat exchangers feature fluids moving perpendicular to one another, enhancing heat transfer by increasing turbulence and mixing, commonly used in applications such as air conditioning and gas cooling.

Fundamental Principles of Flow Arrangements

Parallel-flow heat exchangers feature both the hot and cold fluids entering at the same end and flowing in the same direction, facilitating rapid temperature equilibrium but limiting the maximum temperature difference. Cross-flow arrangements allow one fluid to flow perpendicular to the other, promoting higher heat transfer efficiency by maintaining a more uniform temperature gradient along the flow path. The choice between parallel-flow and cross-flow depends on factors like required heat transfer rate, pressure drop constraints, and thermal performance objectives.

Key Differences Between Parallel-flow and Cross-flow

Parallel-flow heat exchangers have the fluid streams moving in the same direction, resulting in a higher initial temperature gradient but lower overall heat transfer efficiency. Cross-flow heat exchangers allow fluid streams to move perpendicular to each other, enhancing heat transfer by maintaining a more consistent temperature difference across the heat exchanger surface. The key difference lies in flow arrangement, with parallel-flow providing rapid but limited heat transfer, while cross-flow delivers improved thermal performance and is preferred in applications requiring compact design and efficient heat exchange.

Applications in Heat Exchangers

Parallel-flow heat exchangers are commonly used in applications requiring moderate temperature changes, such as in automotive radiators and low-pressure heating systems, where fluids move in the same direction to achieve rapid heat transfer. Cross-flow heat exchangers are preferred in HVAC systems and industrial processes due to their efficient heat transfer capabilities between fluids moving perpendicular to each other, optimizing temperature control in gas-to-liquid or liquid-to-liquid exchanges. Both designs balance thermal efficiency and pressure drop considerations to suit specific operational requirements in power plants, chemical processing, and refrigeration systems.

Efficiency and Performance Comparison

Parallel-flow heat exchangers offer higher heat transfer efficiency at lower pressure drops due to the fluid streams moving in the same direction, promoting uniform temperature gradients. Cross-flow heat exchangers achieve better overall heat transfer performance by optimizing the fluid velocity and surface area, especially in applications requiring compact design and enhanced thermal mixing. Efficiency in parallel-flow systems often decreases as the temperature difference narrows, while cross-flow configurations maintain more consistent performance across varying thermal conditions.

Advantages of Parallel-flow Systems

Parallel-flow systems offer higher heat transfer efficiency due to the uniform temperature difference along the heat exchanger, which enhances overall thermal performance. They minimize the risk of thermal stress since the fluid temperatures increase gradually, promoting equipment longevity. Such systems are advantageous in applications requiring quick temperature control and simplified design, reducing operational and maintenance costs.

Benefits of Cross-flow Configurations

Cross-flow heat exchangers enhance thermal performance by allowing fluid streams to move perpendicular to each other, promoting higher heat transfer efficiency and reduced temperature gradients. This configuration supports compact design and flexible installation, making it ideal for applications requiring space-saving solutions and efficient thermal management. Cross-flow arrangements also minimize pressure drop, leading to lower energy consumption and improved system reliability.

Common Challenges and Limitations

Parallel-flow heat exchangers often face challenges with temperature gradients, leading to lower thermal efficiency due to early temperature equilibrium between fluids. Cross-flow heat exchangers experience limitations in heat transfer rates caused by uneven flow distribution and potential fouling on one side. Both designs must address pressure drop and maintenance difficulties, which impact overall performance and operational costs.

Selection Criteria for Flow Configurations

Selection criteria for parallel-flow versus cross-flow configurations primarily depend on heat transfer efficiency and pressure drop requirements. Parallel-flow heat exchangers offer uniform temperature gradients but typically lower heat transfer coefficients compared to cross-flow, which promotes higher turbulence and better heat transfer performance. Applications with strict maximum allowable pressure drops or temperature approaches favor parallel-flow, while cross-flow is preferred when maximizing heat exchange and handling variable fluid properties is critical.

Conclusion: Choosing the Right Flow Arrangement

Selecting the appropriate flow arrangement between parallel-flow and cross-flow heat exchangers depends on the desired thermal efficiency and application requirements. Parallel-flow systems offer rapid temperature equalization but limited heat transfer, making them suitable for processes needing controlled temperature gradients. Cross-flow designs provide improved heat exchange performance and flexibility, ideal for applications demanding higher heat transfer rates and compact configurations.

Parallel-flow Infographic

libterm.com

libterm.com