Simulation enhances understanding by creating realistic virtual environments that replicate real-world processes or systems. It enables experimentation and analysis without the risks or costs associated with physical trials. Discover how simulation can transform your approach by exploring the full article.

Table of Comparison

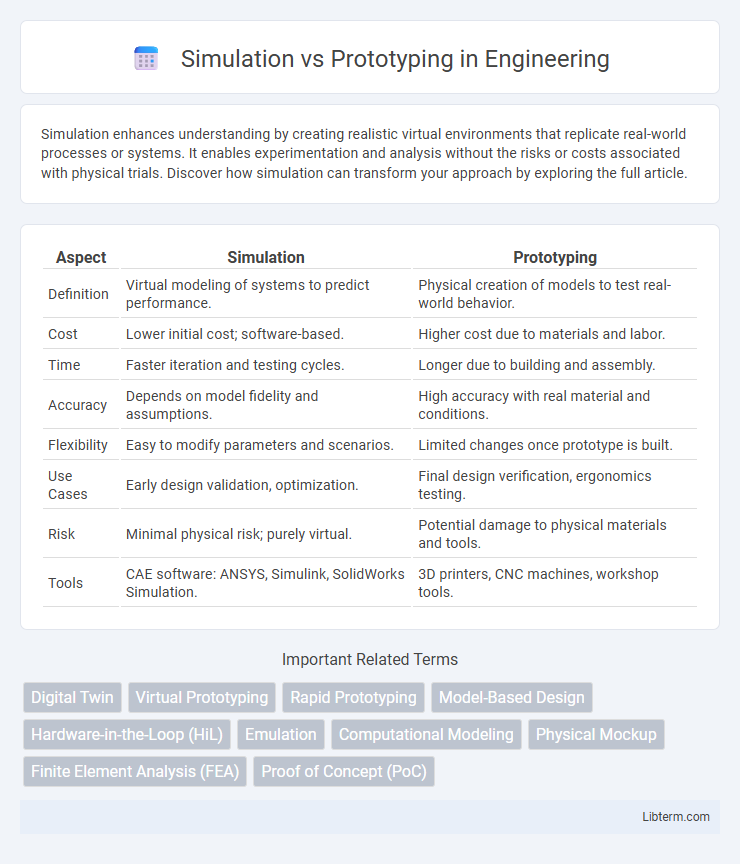

| Aspect | Simulation | Prototyping |

|---|---|---|

| Definition | Virtual modeling of systems to predict performance. | Physical creation of models to test real-world behavior. |

| Cost | Lower initial cost; software-based. | Higher cost due to materials and labor. |

| Time | Faster iteration and testing cycles. | Longer due to building and assembly. |

| Accuracy | Depends on model fidelity and assumptions. | High accuracy with real material and conditions. |

| Flexibility | Easy to modify parameters and scenarios. | Limited changes once prototype is built. |

| Use Cases | Early design validation, optimization. | Final design verification, ergonomics testing. |

| Risk | Minimal physical risk; purely virtual. | Potential damage to physical materials and tools. |

| Tools | CAE software: ANSYS, Simulink, SolidWorks Simulation. | 3D printers, CNC machines, workshop tools. |

Introduction to Simulation and Prototyping

Simulation involves creating a virtual model of a system to analyze its behavior under various conditions, enabling cost-effective testing and optimization before physical development. Prototyping entails building a tangible version of a product or system to validate design concepts and functionality through hands-on evaluation. Both techniques are essential in product development, with simulation emphasizing predictive analysis and prototyping focusing on practical experimentation.

Defining Simulation: Key Concepts

Simulation involves creating a virtual model of a system or process to analyze its behavior under various conditions without physical construction. Key concepts include dynamic modeling, scenario analysis, and real-time data integration that enable prediction and optimization of system performance. This approach reduces time, costs, and risks associated with physical testing, enhancing decision-making efficiency.

Understanding Prototyping: Core Principles

Prototyping centers on creating tangible models that represent key features of a final product, allowing designers to test functionality and gather user feedback early in the development process. This iterative technique emphasizes quick development cycles to identify design flaws and optimize usability before full-scale production. By embodying core principles like realism, interactivity, and adaptability, prototyping accelerates decision-making and reduces costly revisions.

Simulation vs Prototyping: Key Differences

Simulation involves creating a virtual model to analyze system behavior under various conditions without physical construction, whereas prototyping entails building a tangible model to test design functionality. Simulations offer cost-effective, rapid evaluations of multiple scenarios, while prototypes provide hands-on interaction and real-world validation of concepts. The key difference lies in simulation's reliance on digital environments versus prototyping's emphasis on physical form and user experience.

Benefits of Simulation

Simulation offers significant cost savings by enabling virtual testing of designs before physical production, reducing material waste and development expenses. It accelerates the development process through rapid iterations and real-time analysis, allowing engineers to identify and address flaws early. Enhanced accuracy in predicting system behavior under various conditions improves decision-making and product reliability compared to traditional prototyping.

Advantages of Prototyping

Prototyping accelerates design validation by providing tangible models for real-world user feedback and interaction, which enhances usability and detects potential flaws early. It reduces development costs and time by allowing iterative refinements before final production, minimizing the risk of costly post-launch changes. Prototyping facilitates better stakeholder communication and collaboration through a visual and functional representation of the product concept.

When to Use Simulation

Simulation is ideal for testing complex systems and processes in a virtual environment without physical resources, enabling cost-effective analysis of design performance and behavior under various scenarios. It is particularly beneficial during early design stages to identify potential issues, optimize configurations, and evaluate multiple alternatives rapidly. Use simulation when physical prototyping is impractical, expensive, or time-consuming, especially in industries like aerospace, automotive, and electronics.

When to Choose Prototyping

Choose prototyping when tangible user feedback is essential for refining design concepts and usability before final production. It is ideal for complex products requiring iterative testing of physical functionality, ergonomics, and aesthetics that cannot be fully addressed through simulation models. Prototyping accelerates problem identification and stakeholder engagement by providing a hands-on experience that simulation alone cannot replicate.

Integration of Simulation and Prototyping

Integration of simulation and prototyping accelerates product development by combining virtual testing with physical validation, enhancing accuracy and reducing time-to-market. Simulations provide early design insights through digital models, while prototyping offers tangible feedback, enabling iterative refinement and risk mitigation. Leveraging both approaches ensures comprehensive evaluation, improves system integration, and optimizes performance before full-scale production.

Conclusion: Choosing the Right Approach

Choosing between simulation and prototyping depends on project goals, budget, and timeline constraints. Simulation offers cost-effective early-stage analysis, enabling virtual testing and performance prediction, while prototyping provides tangible feedback crucial for user experience and design validation. Integrating both approaches can optimize product development by leveraging simulation's speed and prototyping's realism.

Simulation Infographic

libterm.com

libterm.com