Ball bearings reduce friction and support radial and axial loads in rotating machinery, enhancing operational accuracy and extending equipment lifespan. Their design involves precision steel balls rolling between inner and outer races, minimizing resistance and enabling smooth motion. Explore the rest of this article to discover how ball bearings can improve your mechanical systems' performance.

Table of Comparison

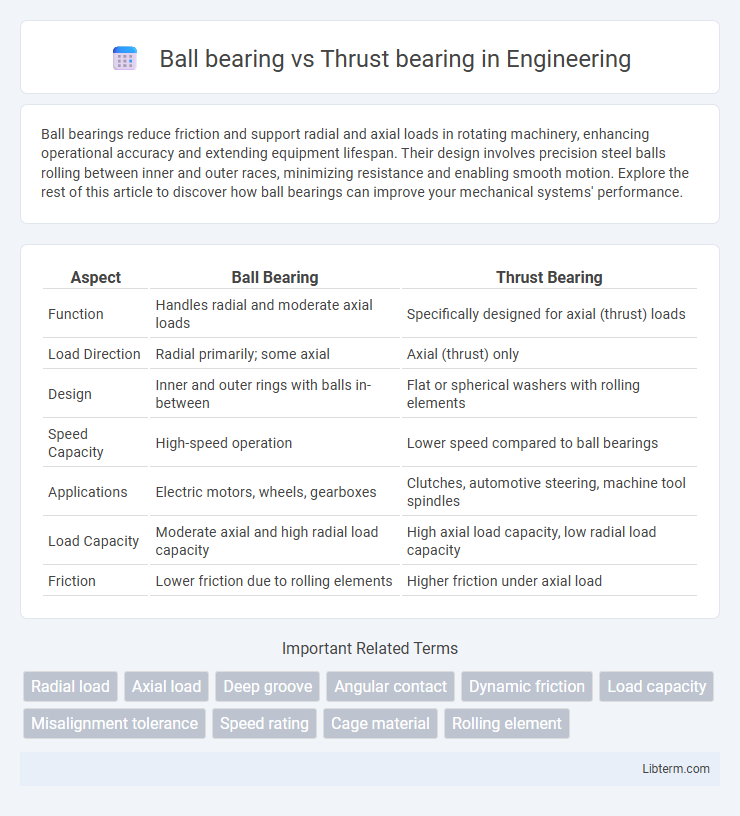

| Aspect | Ball Bearing | Thrust Bearing |

|---|---|---|

| Function | Handles radial and moderate axial loads | Specifically designed for axial (thrust) loads |

| Load Direction | Radial primarily; some axial | Axial (thrust) only |

| Design | Inner and outer rings with balls in-between | Flat or spherical washers with rolling elements |

| Speed Capacity | High-speed operation | Lower speed compared to ball bearings |

| Applications | Electric motors, wheels, gearboxes | Clutches, automotive steering, machine tool spindles |

| Load Capacity | Moderate axial and high radial load capacity | High axial load capacity, low radial load capacity |

| Friction | Lower friction due to rolling elements | Higher friction under axial load |

Introduction: Ball Bearing vs Thrust Bearing

Ball bearings feature spherical rolling elements designed to support radial and axial loads, providing smooth rotation with minimal friction. Thrust bearings are specialized for axial load support, often comprising flat or spherical washers to handle high directional pressure. Selecting between ball and thrust bearings depends on load type, speed, and application requirements for optimal mechanical performance.

Understanding Ball Bearings

Ball bearings consist of spherical rolling elements placed between inner and outer raceways to reduce friction and support radial and axial loads in rotating applications. They offer low rolling resistance and high-speed capabilities, making them ideal for electric motors, automotive wheels, and machinery shafts. Understanding ball bearings involves recognizing their versatility in handling combined loads and ensuring smooth rotational motion in various industrial systems.

What Are Thrust Bearings?

Thrust bearings are specialized components designed to support axial loads, which are forces parallel to the shaft, commonly found in automotive and aerospace applications. Unlike ball bearings that primarily handle radial loads, thrust bearings use a series of flat washers or rollers to distribute the load evenly and reduce friction during rotation. Their ability to manage high axial forces makes them essential for applications requiring precise alignment and smooth rotational movement under heavy axial pressure.

Design Differences

Ball bearings feature radial loads support with balls positioned between inner and outer rings, enabling smooth rotation primarily in radial direction. Thrust bearings are designed to handle axial loads, utilizing flattened rollers or balls arranged to resist forces parallel to the shaft axis. The structural design of thrust bearings often includes a more robust raceway and larger contact area to accommodate higher axial pressure compared to the smaller contact points and radial load emphasis of ball bearings.

Functionality and Applications

Ball bearings primarily facilitate radial and axial loads by reducing friction between rotating shafts and stationary components, making them ideal for high-speed applications such as electric motors and conveyor belts. Thrust bearings are designed to withstand axial loads exclusively, supporting heavy or moderate thrust forces commonly found in automotive transmissions, marine propellers, and machine tool spindles. The distinct load-handling capabilities dictate their use: ball bearings for combined load scenarios and thrust bearings where axial force resistance is critical.

Load Handling Capabilities

Ball bearings are designed primarily to handle radial loads efficiently while providing low friction and smooth rotation, but they have limited axial load capacity. Thrust bearings specialize in supporting high axial loads and are optimized for applications where the load acts parallel to the shaft axis, making them suitable for axial thrust forces. Selecting between ball bearings and thrust bearings depends on whether the primary load is radial or axial, ensuring optimal performance and longevity in mechanical systems.

Durability and Maintenance

Ball bearings offer high durability under radial loads with minimal friction, making them suitable for applications requiring consistent rotation and low maintenance intervals. Thrust bearings, designed to handle axial loads, typically experience higher wear under heavy thrust conditions and require more frequent maintenance to prevent premature failure. Choosing the appropriate bearing type based on load direction and operational demands directly impacts overall durability and maintenance schedules.

Cost Comparison

Ball bearings generally offer a lower initial cost compared to thrust bearings due to simpler design and widespread manufacturing. Thrust bearings, designed to handle axial loads, tend to be more expensive because of specialized materials and construction requirements. Maintenance and replacement costs may also be higher for thrust bearings due to their specific load applications and wear patterns.

Choosing the Right Bearing

Selecting the right bearing depends on load type and direction: ball bearings excel in handling radial loads with moderate axial forces, providing high-speed capabilities and low friction, while thrust bearings are specifically designed to support axial loads and offer superior performance in applications requiring precise axial positioning. Understanding the operational environment, load magnitude, and rotational speed is crucial for optimizing bearing longevity and efficiency. Proper bearing selection enhances machinery reliability by matching load characteristics with bearing design parameters, ensuring optimal performance.

Conclusion: Key Takeaways

Ball bearings excel in handling radial loads and moderate axial forces, making them ideal for rotating shafts in various machinery. Thrust bearings specialize in supporting high axial loads with limited radial capacity, suitable for applications like automotive clutches and turntables. Choosing between ball and thrust bearings depends on load orientation, speed requirements, and specific mechanical design constraints.

Ball bearing Infographic

libterm.com

libterm.com