Brittleness refers to the tendency of a material to fracture or break without significant deformation when subjected to stress. This property is crucial in engineering and manufacturing, as brittle materials can fail suddenly, posing safety risks and affecting product durability. Explore the article to understand how brittleness impacts material selection and performance in various applications.

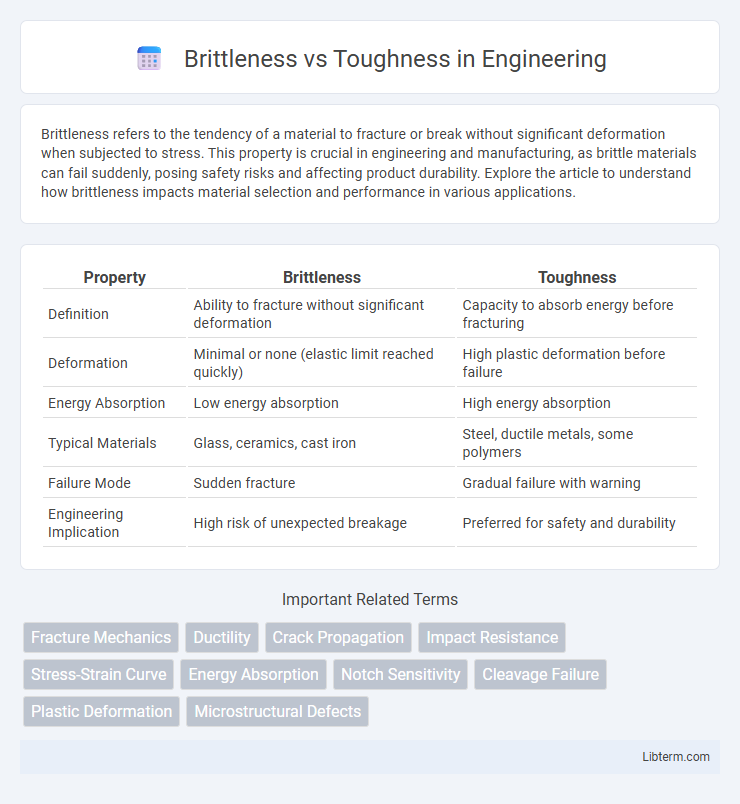

Table of Comparison

| Property | Brittleness | Toughness |

|---|---|---|

| Definition | Ability to fracture without significant deformation | Capacity to absorb energy before fracturing |

| Deformation | Minimal or none (elastic limit reached quickly) | High plastic deformation before failure |

| Energy Absorption | Low energy absorption | High energy absorption |

| Typical Materials | Glass, ceramics, cast iron | Steel, ductile metals, some polymers |

| Failure Mode | Sudden fracture | Gradual failure with warning |

| Engineering Implication | High risk of unexpected breakage | Preferred for safety and durability |

Introduction to Brittleness and Toughness

Brittleness refers to a material's tendency to fracture without significant deformation when subjected to stress, often seen in ceramics and glass. Toughness measures a material's ability to absorb energy and plastically deform before fracturing, indicating resistance to impact and crack propagation. These mechanical properties are critical in selecting materials for applications requiring durability and safety.

Defining Brittleness: Key Characteristics

Brittleness is defined by a material's tendency to fracture or crack without significant deformation under stress, often resulting in sudden failure. Key characteristics include low ductility, minimal plastic deformation, and a high propensity to break when exposed to tensile or impact forces. Materials such as glass, ceramics, and cast iron exemplify brittleness due to their atomic structure and bonding, contributing to their inability to absorb energy before fracturing.

Understanding Toughness: Essential Qualities

Toughness is the material's ability to absorb energy and deform plastically without fracturing, combining both strength and ductility. Unlike brittleness, which leads to sudden failure under stress, toughness ensures resistance to crack propagation and impact loads. Key factors influencing toughness include microstructure, temperature, and strain rate, making it critical for applications requiring durability and safety.

Material Science: Brittleness vs Toughness Explained

Brittleness in material science refers to a material's tendency to fracture without significant deformation, often characterized by low energy absorption before failure. Toughness measures a material's ability to absorb energy and plastically deform without fracturing, indicating resistance to crack propagation under stress. Comparing brittleness and toughness helps engineers select appropriate materials for applications requiring either rigid failure or durability under dynamic loads.

The Role of Atomic Structure in Brittleness and Toughness

Atomic structure significantly influences brittleness and toughness by determining how materials respond to stress at the microscopic level. Materials with a highly ordered, rigid atomic lattice, such as ceramics, tend to be brittle because atomic bonds resist deformation and crack propagation occurs easily. In contrast, metals exhibit toughness due to their atoms arranged in a more flexible lattice that allows dislocation movement, enabling plastic deformation and energy absorption before fracture.

Common Examples of Brittle and Tough Materials

Glass and ceramics are common examples of brittle materials that fracture easily under stress due to their limited ability to deform plastically. Steel and rubber represent tough materials, characterized by their capacity to absorb significant energy and withstand deformation before fracturing. The contrast between these materials highlights the importance of selecting appropriate substances based on required mechanical properties for applications in construction, manufacturing, and engineering.

Factors Affecting Material Brittleness

Material brittleness is influenced by temperature, with lower temperatures typically increasing brittleness due to reduced atomic mobility in the microstructure. Alloy composition also plays a crucial role, where the presence of impurities or specific alloying elements can enhance crack initiation and propagation. Grain size impacts brittleness as finer grains tend to improve toughness, while coarse grains often lead to increased brittleness by facilitating crack growth.

Factors Influencing Material Toughness

Material toughness is primarily influenced by factors such as grain size, temperature, and strain rate. Smaller grain sizes enhance toughness by impeding crack propagation, while higher temperatures generally increase ductility, improving toughness. Slow strain rates allow materials to deform plastically, thus increasing energy absorption before fracture.

Industrial Applications: Choosing Between Brittleness and Toughness

In industrial applications, toughness is critical for materials subjected to impact and dynamic loads, such as in automotive and aerospace components, where resistance to crack propagation prevents catastrophic failure. Brittleness may be preferred in precision machining and cutting tools where hardness and minimal deformation enable sharp edges and high wear resistance. Selecting between brittleness and toughness depends on balancing mechanical requirements with operational conditions to optimize performance and durability.

Future Trends in Enhancing Material Toughness and Reducing Brittleness

Advanced nanomaterials and engineered composites are driving future trends in enhancing material toughness while reducing brittleness by optimizing microstructural properties and energy absorption mechanisms. Emerging techniques like biomimetic designs and self-healing materials are expected to revolutionize structural integrity in aerospace, automotive, and civil engineering applications. Integration of machine learning models for predictive toughness and brittleness behavior accelerates the development of smarter, more resilient materials tailored for extreme environments.

Brittleness Infographic

libterm.com

libterm.com