Ball valves provide reliable shutoff with a simple quarter-turn operation, making them ideal for controlling fluid flow in pipelines. Their durable design ensures minimal leakage and easy maintenance, enhancing the efficiency of various industrial and residential applications. Explore the rest of this article to learn how ball valves can optimize your system's performance.

Table of Comparison

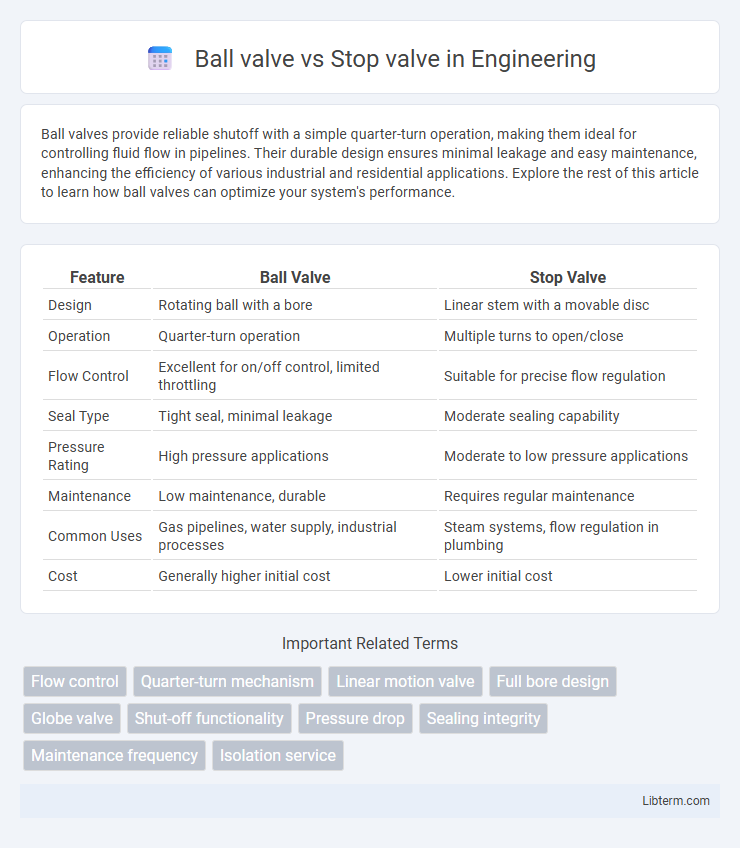

| Feature | Ball Valve | Stop Valve |

|---|---|---|

| Design | Rotating ball with a bore | Linear stem with a movable disc |

| Operation | Quarter-turn operation | Multiple turns to open/close |

| Flow Control | Excellent for on/off control, limited throttling | Suitable for precise flow regulation |

| Seal Type | Tight seal, minimal leakage | Moderate sealing capability |

| Pressure Rating | High pressure applications | Moderate to low pressure applications |

| Maintenance | Low maintenance, durable | Requires regular maintenance |

| Common Uses | Gas pipelines, water supply, industrial processes | Steam systems, flow regulation in plumbing |

| Cost | Generally higher initial cost | Lower initial cost |

Introduction to Ball Valves and Stop Valves

Ball valves are quarter-turn valves designed for quick shutoff, featuring a rotatable ball with a central bore that controls flow efficiently in pipelines, commonly used in industrial and residential applications. Stop valves, on the other hand, operate by moving a flat or tapered disc perpendicularly to the flow, enabling more precise control and are often used for throttling and isolation in plumbing systems. Both valve types serve critical roles in fluid management, with ball valves providing fast, reliable shutoff and stop valves offering fine flow regulation.

Key Differences Between Ball Valve and Stop Valve

Ball valves feature a spherical disc to control flow, offering quick quarter-turn operation and excellent sealing for tight shutoff, making them ideal for high-pressure systems. Stop valves use a linear motion with a rising or non-rising stem to gradually open or close flow, providing precise throttling and control but slower operation. The key differences lie in their design, flow control efficiency, speed of operation, and typical applications, with ball valves preferred for rapid shutoff and stop valves favored for flow regulation.

How Ball Valves Work: Mechanism and Applications

Ball valves operate through a rotary ball with a bore, which aligns with the pipeline when open to allow fluid flow and rotates 90 degrees to seal off flow when closed, providing tight shutoff and minimal pressure drop. These valves are widely used in industries such as oil and gas, water treatment, and chemical processing, where quick, reliable shutoff and durability under high pressure and temperature are critical. Their simple mechanism offers low torque operation and excellent sealing, making them ideal for both on/off control and throttling service in pipelines.

Stop Valves: Functionality and Common Uses

Stop valves regulate fluid flow by completely halting or allowing passage within plumbing systems, providing precise control in residential and industrial applications. Commonly found in water supply lines and heating systems, they prevent backflow and isolate sections for maintenance. Their simple mechanism ensures reliable shut-off, making them essential for emergency and routine plumbing tasks.

Advantages of Using Ball Valves

Ball valves offer quick shutoff capabilities with a simple quarter-turn operation, ensuring efficient flow control and minimal pressure drop. Their robust design provides excellent durability and leak-proof performance, ideal for high-pressure and high-temperature applications. Compared to stop valves, ball valves require less maintenance and deliver faster response times, enhancing operational reliability in industrial and residential plumbing systems.

Benefits and Drawbacks of Stop Valves

Stop valves provide precise flow control and reliable shutoff in plumbing systems, making them ideal for maintenance and emergency use. Their compact design and ability to throttle flow offer advantages in regulating pressure but may cause wear over time, leading to potential leaks. Limited to on/off functionality compared to ball valves, stop valves are less durable under high-pressure conditions and require more frequent maintenance.

Ball Valve vs Stop Valve: Flow Control Comparison

Ball valves provide quick, reliable shutoff with a 90-degree turn, ensuring minimal flow resistance and tight sealing, ideal for on/off control in high-pressure systems. Stop valves offer more precise flow regulation through gradual stem rotation, allowing fine adjustment but generating higher pressure drops due to partially restricted flow paths. Comparing flow control, ball valves excel in efficiency and durability, while stop valves enable detailed flow modulation at the cost of reduced flow capacity.

Durability and Maintenance: Which Valve Lasts Longer?

Ball valves offer superior durability due to their robust design with a spherical closure element that resists wear and corrosion, making them ideal for high-pressure and high-flow applications. Stop valves, typically featuring a rising stem and a disc, are more prone to leakage and wear over time, requiring more frequent maintenance and part replacements. The low-maintenance nature of ball valves, combined with longer service life and minimal sealing degradation, generally ensures they last longer than stop valves in industrial and residential systems.

Cost-Effectiveness: Ball Valve vs Stop Valve

Ball valves generally offer greater cost-effectiveness due to their durability and lower maintenance requirements, making them ideal for frequent operation and long-term use. Stop valves, while initially less expensive, may incur higher maintenance costs over time because of their more complex design and susceptibility to wear. Evaluating the total lifecycle cost reveals ball valves as the better investment for applications demanding reliable, efficient valve performance.

Choosing the Right Valve: Practical Selection Tips

Ball valves provide quick, reliable shutoff with minimal pressure drop, making them ideal for applications requiring rapid flow control and tight sealing. Stop valves offer finer flow regulation with gradual opening and closing, suitable for systems needing precise flow adjustments or throttling. When choosing the right valve, consider factors such as flow control precision, operating pressure, maintenance frequency, and space constraints to ensure optimal performance and longevity.

Ball valve Infographic

libterm.com

libterm.com