Poisson's ratio measures the ratio of transverse strain to axial strain in a material subjected to axial stress, revealing how materials deform under load. This fundamental property plays a crucial role in material science and engineering design, influencing stress distribution and stability. Discover how understanding Poisson's ratio can enhance your insights into material behavior by reading the full article.

Table of Comparison

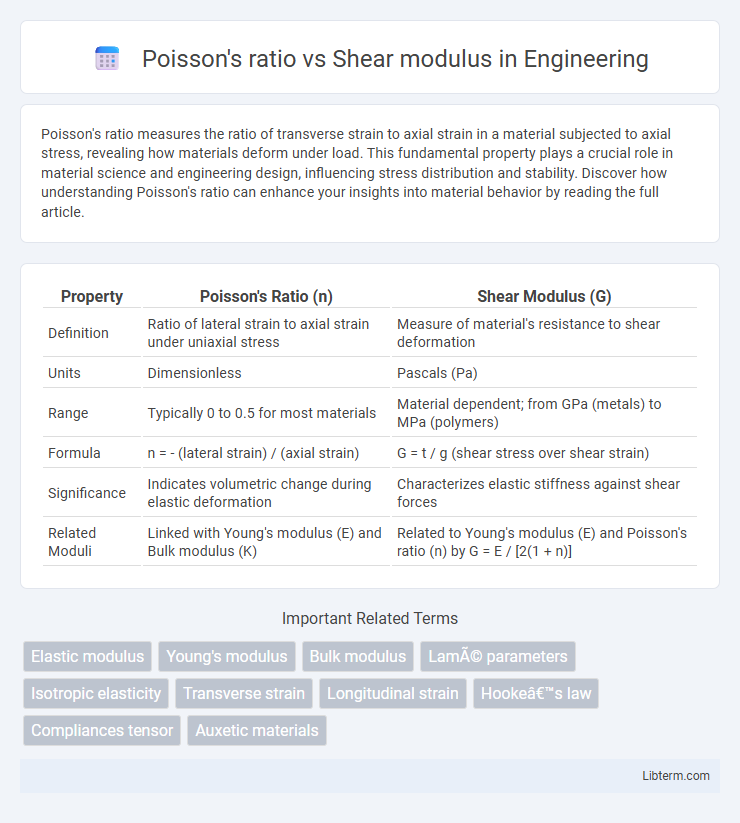

| Property | Poisson's Ratio (n) | Shear Modulus (G) |

|---|---|---|

| Definition | Ratio of lateral strain to axial strain under uniaxial stress | Measure of material's resistance to shear deformation |

| Units | Dimensionless | Pascals (Pa) |

| Range | Typically 0 to 0.5 for most materials | Material dependent; from GPa (metals) to MPa (polymers) |

| Formula | n = - (lateral strain) / (axial strain) | G = t / g (shear stress over shear strain) |

| Significance | Indicates volumetric change during elastic deformation | Characterizes elastic stiffness against shear forces |

| Related Moduli | Linked with Young's modulus (E) and Bulk modulus (K) | Related to Young's modulus (E) and Poisson's ratio (n) by G = E / [2(1 + n)] |

Introduction to Poisson’s Ratio and Shear Modulus

Poisson's ratio measures the lateral strain to axial strain ratio when a material is stretched, reflecting its deformation behavior under tensile stress. Shear modulus quantifies a material's ability to resist shear deformation, defined as the ratio of shear stress to shear strain. Both parameters are fundamental in characterizing elastic properties, with Poisson's ratio influencing volumetric changes and shear modulus determining rigidity in solid materials.

Fundamental Definitions

Poisson's ratio quantifies the ratio of transverse strain to axial strain in a material subjected to uniaxial stress, offering insight into its deformation characteristics. The shear modulus, or modulus of rigidity, measures a material's response to shear stress, indicating its resistance to shape changes without volume alteration. Both parameters are essential in defining elastic properties, with Poisson's ratio linking lateral and axial strains and shear modulus describing the material's shear stiffness.

Mathematical Relationships between Poisson’s Ratio and Shear Modulus

Poisson's ratio (n) and shear modulus (G) are intrinsically linked through the elastic modulus (E) in isotropic materials, governed by the relationship G = E / [2(1 + n)]. This equation highlights that as Poisson's ratio approaches 0.5, the shear modulus reduces for a constant elastic modulus, reflecting material incompressibility. Understanding this mathematical coupling is essential for precise calculations in elasticity, structural analysis, and material science applications.

Significance in Material Science

Poisson's ratio and shear modulus are fundamental mechanical properties that describe a material's deformation response under stress, with Poisson's ratio measuring the transverse strain to axial strain ratio and shear modulus quantifying the material's resistance to shear deformation. Understanding the relationship between these two parameters is critical in material science for predicting elastic behavior, designing composites, and optimizing materials for structural applications. Precise knowledge of both properties enables engineers to tailor materials for specific mechanical demands, enhance durability, and improve performance in aerospace, civil engineering, and manufacturing industries.

How Poisson’s Ratio Influences Shear Modulus

Poisson's ratio directly affects the shear modulus by dictating the material's lateral strain response to axial stress, where an increase in Poisson's ratio typically results in a decrease in shear modulus for isotropic materials. The shear modulus (G) is mathematically related to Young's modulus (E) and Poisson's ratio (n) through the equation G = E / [2(1 + n)], emphasizing that higher Poisson's ratio values reduce the shear modulus. This relationship is critical in material science and mechanical engineering for predicting deformation behavior under shear stress based on Poisson's ratio.

Comparison in Different Materials

Poisson's ratio and shear modulus are fundamental mechanical properties that characterize a material's deformation behavior under stress. Materials like metals typically exhibit moderate Poisson's ratios (0.25-0.35) and high shear moduli, indicating strong resistance to shape changes, whereas polymers often have higher Poisson's ratios (up to 0.5) paired with lower shear moduli, reflecting greater flexibility and softer response. Ceramics show low Poisson's ratios (0.1-0.25) and variable shear moduli but generally possess brittle qualities, making the interplay between these parameters crucial for tailoring materials in structural and flexible applications.

Practical Applications and Engineering Examples

Poisson's ratio and shear modulus are crucial parameters in engineering for assessing material deformation and stress response under load. Poisson's ratio helps predict volumetric changes in structures like beams and plates, essential in civil engineering for evaluating concrete and steel behavior. The shear modulus directly influences the design of shafts, gears, and springs by quantifying a material's resistance to shear stress, critical in mechanical and aerospace engineering applications.

Graphical Representation and Analysis

Graphical representation of Poisson's ratio versus shear modulus typically shows an inverse relationship for isotropic materials, where an increase in shear modulus corresponds to a decrease in Poisson's ratio within specific material classes. Analysis of such graphs reveals that materials with high shear modulus, like metals, tend to have lower Poisson's ratios, indicating less lateral expansion under axial stress. Data plots often use contour maps or scatter plots to highlight material behavior under different stress states, facilitating precise interpretation of elasticity and deformation characteristics.

Limitations and Considerations

Poisson's ratio and shear modulus are critical mechanical parameters but have limitations in anisotropic or composite materials where their values may not remain constant. Poisson's ratio typically ranges between 0 and 0.5 for most isotropic materials, but can be negative in auxetic materials, complicating direct correlation with shear modulus. Shear modulus is directly related to elasticity and deformation under shear stress, but assumptions of linear elasticity and isotropy limit its applicability in complex structures or under large strains.

Summary and Key Takeaways

Poisson's ratio quantifies the ratio of lateral strain to axial strain in a material under axial loading, typically ranging between 0 and 0.5 for most solids. The shear modulus measures a material's rigidity or resistance to shear deformation, defined as the ratio of shear stress to shear strain. Both properties are interrelated through the material's elastic constants, with Poisson's ratio providing critical insights into volumetric changes and the shear modulus indicating material stiffness under tangential forces.

Poisson's ratio Infographic

libterm.com

libterm.com