Yield strength defines the maximum stress a material can endure without permanent deformation, making it crucial for engineering applications where structural integrity is essential. Understanding this property helps you select the right materials to ensure safety and performance under load. Explore the rest of the article to learn how yield strength impacts material selection and design.

Table of Comparison

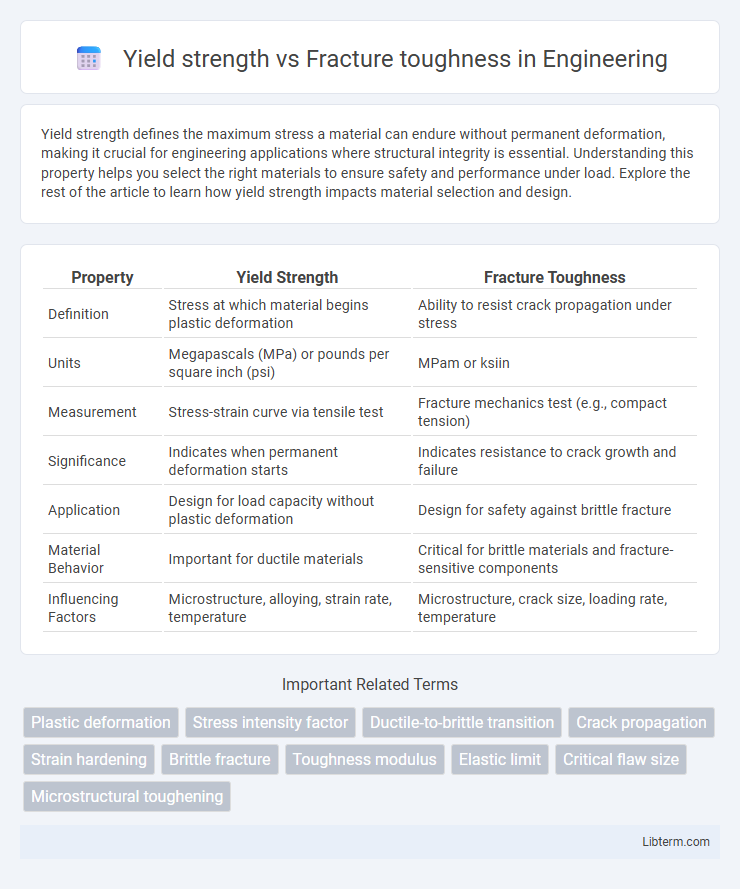

| Property | Yield Strength | Fracture Toughness |

|---|---|---|

| Definition | Stress at which material begins plastic deformation | Ability to resist crack propagation under stress |

| Units | Megapascals (MPa) or pounds per square inch (psi) | MPam or ksiin |

| Measurement | Stress-strain curve via tensile test | Fracture mechanics test (e.g., compact tension) |

| Significance | Indicates when permanent deformation starts | Indicates resistance to crack growth and failure |

| Application | Design for load capacity without plastic deformation | Design for safety against brittle fracture |

| Material Behavior | Important for ductile materials | Critical for brittle materials and fracture-sensitive components |

| Influencing Factors | Microstructure, alloying, strain rate, temperature | Microstructure, crack size, loading rate, temperature |

Introduction to Yield Strength and Fracture Toughness

Yield strength defines the maximum stress a material can withstand without permanent deformation, serving as a critical parameter for structural integrity and performance. Fracture toughness measures a material's ability to resist crack propagation, essential for evaluating durability under stress concentration and preventing catastrophic failure. Both properties are fundamental in material selection for engineering applications, influencing safety and longevity in mechanical components.

Defining Yield Strength

Yield strength defines the maximum stress a material can withstand without permanent deformation, marking the elastic-to-plastic transition point. It is a critical factor in designing components subject to mechanical loads, ensuring structures remain intact under operational stresses. Yield strength is distinct from fracture toughness, which measures a material's ability to resist crack propagation and failure under stress.

Understanding Fracture Toughness

Fracture toughness measures a material's ability to resist crack propagation under stress, providing critical insight into its structural integrity beyond yield strength, which simply defines the stress level causing permanent deformation. Unlike yield strength, fracture toughness accounts for flaws and cracks, making it essential for predicting failure in brittle and ductile materials. Understanding fracture toughness enables engineers to design safer components by evaluating how materials behave under complex loading conditions and preventing catastrophic fractures.

Key Differences Between Yield Strength and Fracture Toughness

Yield strength measures the maximum stress a material can withstand without permanent deformation, while fracture toughness quantifies a material's ability to resist crack propagation under stress. Yield strength is critical for predicting when a material will undergo plastic deformation, whereas fracture toughness assesses resistance to brittle failure in the presence of flaws. Materials with high yield strength are strong, but may have low fracture toughness, making it essential to balance both properties for structural integrity.

Material Behavior Under Stress: Yielding vs Fracture

Yield strength defines the stress level at which a material begins to deform plastically, marking the transition from elastic to permanent deformation, while fracture toughness quantifies a material's ability to resist crack propagation and catastrophic failure. Materials with high yield strength can withstand significant applied stress before deforming, but low fracture toughness means they are more prone to sudden fracture under stress concentration. Understanding the interplay between yield strength and fracture toughness is crucial for predicting material behavior under complex loading and preventing failure in structural applications.

Factors Influencing Yield Strength

Yield strength is primarily influenced by factors such as grain size, strain hardening, temperature, and the presence of alloying elements, which enhance a material's ability to withstand elastic deformation. Smaller grain sizes increase yield strength through the Hall-Petch effect by impeding dislocation movement. In contrast, fracture toughness depends on a material's ability to resist crack propagation and is influenced by microstructural properties, flaw size, and loading conditions.

Factors Affecting Fracture Toughness

Fracture toughness primarily depends on material microstructure, temperature, loading rate, and the presence of stress concentrators such as cracks or notches. Grain size significantly influences fracture toughness, with finer grains typically enhancing resistance to crack propagation. Environmental factors like corrosion and hydrogen embrittlement can also degrade fracture toughness, while yield strength generally correlates with resistance to plastic deformation but does not fully predict fracture resistance.

Testing and Measurement Methods

Yield strength is typically measured using tensile testing, where a specimen is subjected to controlled tension until it deforms plastically, providing values via stress-strain curves generated by universal testing machines. Fracture toughness is assessed through fracture mechanics tests like the Single Edge Notch Bend (SENB) or Compact Tension (CT) tests, which analyze crack propagation resistance under applied stress and provide critical stress intensity factors (K_IC). Both methods require precise specimen preparation and instrumentation, including extensometers for strain measurement and load cells for force application, ensuring accurate determination of material performance under different loading conditions.

Practical Applications in Engineering and Design

Yield strength determines the maximum stress a material can withstand without permanent deformation, crucial for structural components subjected to high loads. Fracture toughness measures a material's resistance to crack propagation, essential for assessing durability and safety in critical applications like aerospace and pressure vessels. Engineers balance these properties to optimize design, ensuring components maintain integrity under stress while preventing catastrophic failure.

Selecting Materials Based on Yield Strength and Fracture Toughness

Selecting materials based on yield strength and fracture toughness requires balancing resistance to plastic deformation with the ability to resist crack propagation under stress. High yield strength materials perform well under static loads but may exhibit lower fracture toughness, increasing susceptibility to brittle failure. Engineers must evaluate the application's loading conditions and environmental factors to optimize material choice for both strength and durability.

Yield strength Infographic

libterm.com

libterm.com