Homogenization is a mechanical process that breaks down fat molecules in milk, ensuring an even distribution and preventing cream separation. This technique improves texture, taste, and shelf life of dairy products by creating a smoother, more consistent product. Discover how homogenization impacts the quality of your favorite dairy items in the rest of this article.

Table of Comparison

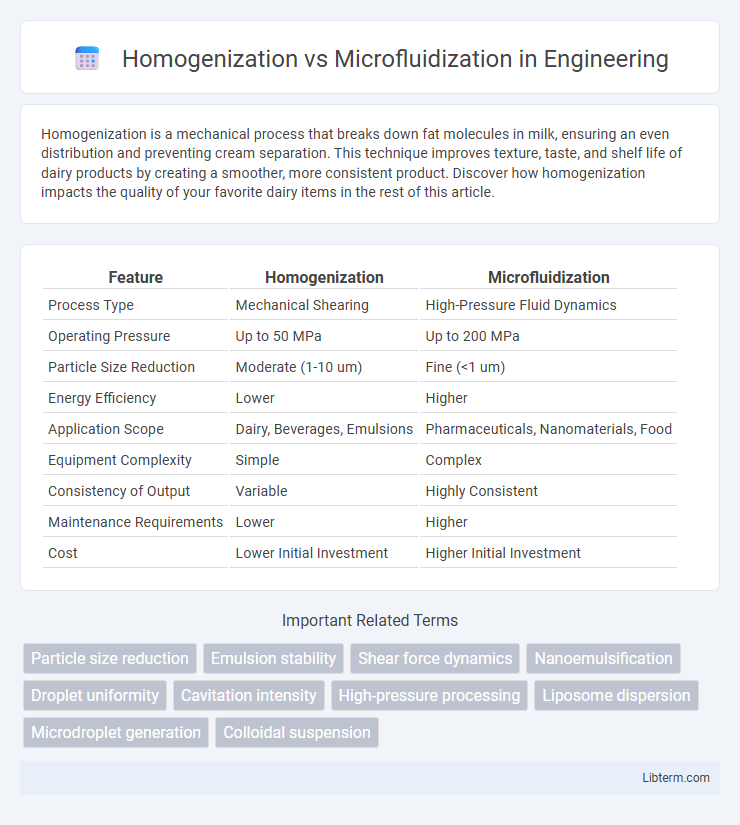

| Feature | Homogenization | Microfluidization |

|---|---|---|

| Process Type | Mechanical Shearing | High-Pressure Fluid Dynamics |

| Operating Pressure | Up to 50 MPa | Up to 200 MPa |

| Particle Size Reduction | Moderate (1-10 um) | Fine (<1 um) |

| Energy Efficiency | Lower | Higher |

| Application Scope | Dairy, Beverages, Emulsions | Pharmaceuticals, Nanomaterials, Food |

| Equipment Complexity | Simple | Complex |

| Consistency of Output | Variable | Highly Consistent |

| Maintenance Requirements | Lower | Higher |

| Cost | Lower Initial Investment | Higher Initial Investment |

Introduction to Homogenization and Microfluidization

Homogenization is a mechanical process that reduces particle size and creates uniform mixtures by forcing a liquid through a narrow space under high pressure, commonly used in dairy and pharmaceutical industries. Microfluidization employs high-velocity fluid streams that collide within microchannels, achieving finer particle size reduction and enhanced product consistency compared to traditional homogenization. Both technologies optimize emulsification and dispersion but differ in energy efficiency, particle size control, and application specificity.

Fundamental Principles of Homogenization

Homogenization relies on mechanical forces such as shear, turbulence, and cavitation to reduce particle size and create a uniform mixture by forcing fluids through narrow gaps under high pressure. This process disrupts droplets and particles, enhancing product stability and texture in emulsions and suspensions. Compared to microfluidization, which uses fixed-geometry microchannels for more precise particle size control, homogenization remains a widely applied method for achieving fine dispersion in various industries.

Core Mechanisms of Microfluidization

Microfluidization uses high-pressure streams forced through microchannels to generate intense shear, impact, and cavitation effects, leading to uniform particle size reduction and enhanced product stability. Unlike traditional homogenization, which relies primarily on mechanical shear and turbulence, microfluidization achieves finer emulsions and dispersions through controlled fluid dynamics in interaction chambers. This core mechanism improves bioavailability and texture in pharmaceuticals, food, and cosmetic formulations by creating nanoscale particles and consistent microstructures.

Key Equipment Differences

Homogenization uses high-pressure pumps that force fluids through narrow gaps, generating shear and turbulence for particle size reduction, ideal for basic emulsification tasks. Microfluidization employs microchannels and fixed-geometry interaction chambers where fluid streams collide at high velocities, producing uniform particle sizes and enhanced product stability. The specialized design of microfluidizers allows for precise control over particle size distribution compared to conventional homogenizers.

Impact on Particle Size Reduction

Homogenization typically reduces particle sizes to the micrometer range through high-pressure shear forces, making it effective for emulsions and suspensions. Microfluidization employs high-velocity fluid streams and impingement, achieving finer particle size reduction down to the nanometer scale with greater uniformity. This advanced technique enhances stability and bioavailability in pharmaceuticals and food products by producing more consistent and smaller particles than traditional homogenization.

Efficiency in Emulsification and Suspension Stability

Microfluidization offers superior efficiency in emulsification compared to traditional homogenization due to its high-pressure jet stream technology, producing finer droplet sizes and more uniform particle distribution. This enhanced emulsification directly contributes to improved suspension stability by minimizing phase separation and increasing the product's shelf life. Studies show microfluidized emulsions exhibit lower polydispersity indices and higher zeta potential, ensuring better long-term stability in pharmaceutical and food applications.

Applications Across Industries

Homogenization is widely used in dairy processing, pharmaceuticals, and cosmetics to improve product stability and texture by reducing particle size and ensuring uniform dispersion. Microfluidization offers superior emulsification and nanoemulsion capabilities, making it ideal for advanced drug delivery systems, biofuel production, and high-quality food and beverage formulations. Both technologies enhance product consistency and performance, with microfluidization providing higher precision for applications requiring ultra-fine particle sizes.

Energy Consumption and Operational Costs

Microfluidization typically consumes less energy than traditional homogenization due to its efficient processing mechanism that generates finer emulsions at lower pressures. Operational costs for microfluidization are often lower over time, as reduced energy demands and lower maintenance requirements result in cost savings despite higher initial equipment investments. Homogenization may have higher energy consumption and increased wear on parts, leading to greater operational expenses in large-scale production.

Product Quality and Consistency Comparison

Microfluidization produces finer and more uniform particle sizes compared to traditional homogenization, resulting in enhanced product stability and improved texture consistency. The high-pressure microfluidization process ensures superior dispersion of ingredients, reducing batch-to-batch variability and increasing overall product quality. Homogenization often leads to larger particle sizes and less uniform emulsions, which can cause inconsistency in flavor and appearance.

Choosing the Right Technology for Specific Needs

Selecting between homogenization and microfluidization depends on particle size reduction requirements and product consistency goals. Homogenization is ideal for moderate particle size reduction and emulsification in dairy and beverage industries, while microfluidization achieves finer emulsions and higher uniformity, suitable for pharmaceuticals and cosmetics. Consider processing scale, pressure capacity, and product sensitivity to optimize technology choice for specific industrial applications.

Homogenization Infographic

libterm.com

libterm.com