The Hall effect occurs when a magnetic field is applied perpendicular to the flow of electric current in a conductor, creating a voltage difference across the material. This phenomenon is crucial in measuring magnetic field strength and characterizing semiconductor properties. Discover how the Hall effect influences your everyday technology and learn more in the detailed article ahead.

Table of Comparison

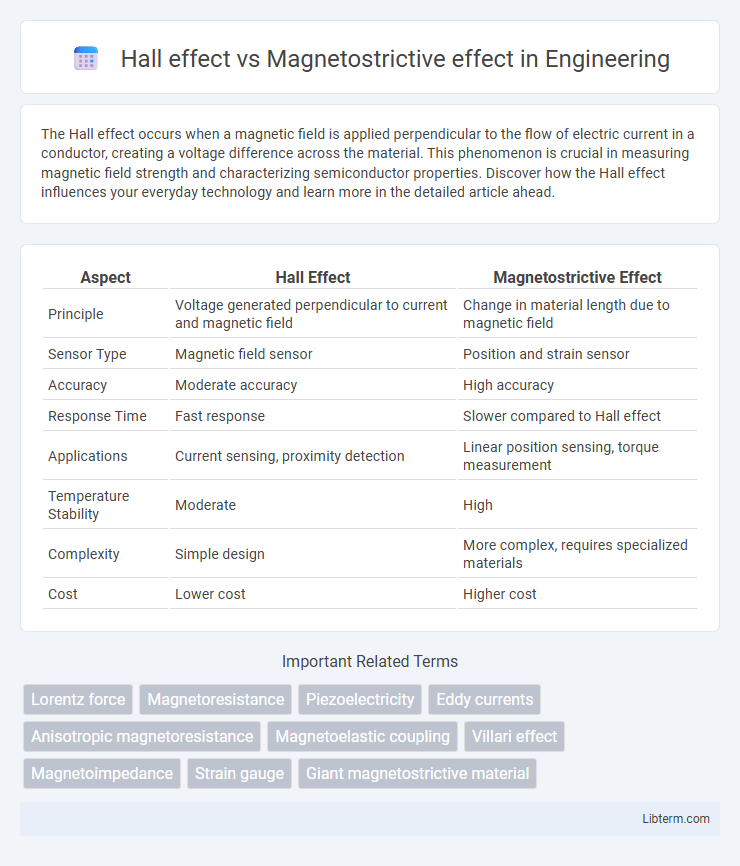

| Aspect | Hall Effect | Magnetostrictive Effect |

|---|---|---|

| Principle | Voltage generated perpendicular to current and magnetic field | Change in material length due to magnetic field |

| Sensor Type | Magnetic field sensor | Position and strain sensor |

| Accuracy | Moderate accuracy | High accuracy |

| Response Time | Fast response | Slower compared to Hall effect |

| Applications | Current sensing, proximity detection | Linear position sensing, torque measurement |

| Temperature Stability | Moderate | High |

| Complexity | Simple design | More complex, requires specialized materials |

| Cost | Lower cost | Higher cost |

Introduction to Hall Effect and Magnetostrictive Effect

The Hall effect occurs when a magnetic field applied perpendicular to an electric current in a conductor generates a voltage transverse to the current, enabling precise magnetic field sensing and current measurement. The magnetostrictive effect involves the change in shape or dimensions of ferromagnetic materials under the influence of a magnetic field, making it essential for sensors, actuators, and transducers. Both phenomena play critical roles in modern magnetic sensing technologies but operate on fundamentally different physical principles--Hall effect based on charge carrier deflection and magnetostriction based on material strain responses.

Fundamental Principles of the Hall Effect

The Hall effect arises from the deflection of charge carriers, such as electrons, by a magnetic field perpendicular to the current flow, generating a measurable voltage across the conductor. This voltage, known as the Hall voltage, is directly proportional to the magnetic field strength and the current, enabling precise measurement of magnetic fields and carrier concentration in materials. Unlike the magnetostrictive effect, which involves mechanical deformation of ferromagnetic materials under magnetic influence, the Hall effect operates on charge carrier dynamics and electromagnetic forces at the microscopic level.

Fundamental Principles of the Magnetostrictive Effect

The magnetostrictive effect arises from the change in shape or dimensions of ferromagnetic materials when exposed to a magnetic field, due to the reorientation of magnetic domains causing strain at the atomic level. Unlike the Hall effect, which involves voltage generation perpendicular to current and magnetic field in conductors, magnetostriction involves magneto-mechanical coupling that converts magnetic energy into mechanical deformation. This fundamental principle underpins applications in sensors, actuators, and transducers leveraging magnetostrictive materials such as Terfenol-D and nickel alloys.

Key Differences Between Hall Effect and Magnetostrictive Effect

The Hall effect generates a voltage difference perpendicular to an electric current in a conductor within a magnetic field, primarily used for sensing magnetic field strength and position. The magnetostrictive effect involves the change in shape or dimensions of a ferromagnetic material when exposed to a magnetic field, commonly applied in sensors and actuators for stress and vibration measurement. Key differences include the Hall effect being an electromagnetic phenomenon producing voltage output, while the magnetostrictive effect is a mechanical deformation effect causing dimensional changes.

Material Requirements: Hall Effect vs Magnetostrictive Effect

The Hall effect relies on semiconducting materials such as indium antimonide or gallium arsenide with high carrier mobility for sensitive voltage generation under magnetic fields. Magnetostrictive effect requires ferromagnetic materials like nickel, iron, or Terfenol-D, which exhibit significant strain or dimensional changes when exposed to magnetic fields. Material purity, crystal structure, and magnetic domain configuration critically influence the performance of both effects in sensing and actuator applications.

Applications in Sensor Technology

Hall effect sensors are widely used in automotive and industrial applications for precise current, position, and speed sensing due to their contactless operation and high reliability. Magnetostrictive sensors excel in linear position measurement and torque sensing with exceptional accuracy and durability, making them ideal for harsh environments like oil and gas or manufacturing automation. Both technologies enable real-time monitoring and control in sensor technology, enhancing system efficiency and safety across diverse industries.

Advantages and Limitations of Hall Effect Sensors

Hall effect sensors offer precise magnetic field measurement, fast response time, and non-contact operation, making them ideal for applications like position sensing and current measurement. They are robust against environmental factors such as dust and vibrations but have limitations including sensitivity to temperature variations and relatively low output signal strength. Compared to magnetostrictive sensors, Hall effect sensors are generally more cost-effective and compact but provide lower resolution and accuracy in displacement detection.

Advantages and Limitations of Magnetostrictive Sensors

Magnetostrictive sensors offer high accuracy and durability, making them ideal for precise position and displacement measurements in harsh environments due to their contactless operation and resistance to wear. Their limitations include sensitivity to external magnetic fields and temperature variations, which can affect measurement stability and require compensation techniques. Compared to Hall effect sensors, magnetostrictive sensors generally provide better linearity and higher resolution but at a higher cost and increased complexity in signal processing.

Performance Comparison: Sensitivity, Accuracy, and Durability

The Hall effect sensor exhibits high sensitivity and accuracy in detecting magnetic fields, making it ideal for precise position and current measurements, whereas the magnetostrictive effect offers superior durability and robustness in extreme environments due to its mechanical strain-based sensing mechanism. Hall effect devices provide faster response times and lower power consumption but may suffer from temperature drift, while magnetostrictive sensors maintain stable performance over a wider temperature range with minimal signal degradation. In applications requiring long-term reliability and resistance to mechanical wear, magnetostrictive sensors outperform Hall effect sensors despite slightly lower sensitivity.

Future Trends and Innovations in Magnetic Sensing Technologies

Future trends in magnetic sensing technologies emphasize enhanced sensitivity and miniaturization, leveraging the Hall effect for compact, low-power applications in IoT devices and automotive systems. Innovations in magnetostrictive effect sensors focus on integrating flexible materials and nanostructures to achieve higher precision and durability in harsh environments like industrial monitoring and wearable health devices. The convergence of AI-driven data analytics with these magnetic sensing techniques is driving smarter, adaptive systems for real-time magnetic field detection and material stress analysis.

Hall effect Infographic

libterm.com

libterm.com