Mean time to failure (MTTF) is a key reliability metric indicating the average operational lifespan of non-repairable systems before failure occurs. It helps manufacturers and users predict product durability and plan maintenance schedules to minimize downtime. Discover how understanding MTTF can enhance your equipment management by reading the full article.

Table of Comparison

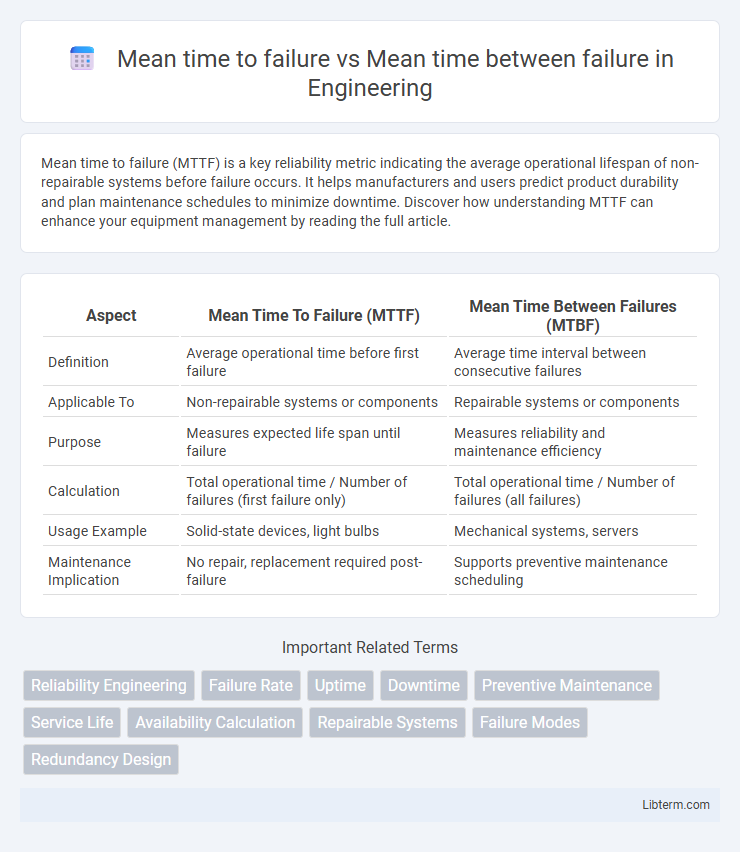

| Aspect | Mean Time To Failure (MTTF) | Mean Time Between Failures (MTBF) |

|---|---|---|

| Definition | Average operational time before first failure | Average time interval between consecutive failures |

| Applicable To | Non-repairable systems or components | Repairable systems or components |

| Purpose | Measures expected life span until failure | Measures reliability and maintenance efficiency |

| Calculation | Total operational time / Number of failures (first failure only) | Total operational time / Number of failures (all failures) |

| Usage Example | Solid-state devices, light bulbs | Mechanical systems, servers |

| Maintenance Implication | No repair, replacement required post-failure | Supports preventive maintenance scheduling |

Introduction to MTBF and MTTF

Mean Time Between Failure (MTBF) measures the average time elapsed between inherent failures of a system during operation, primarily applicable to repairable systems, while Mean Time To Failure (MTTF) represents the average time until a non-repairable system fails. MTBF is crucial in reliability engineering for predicting system uptime and scheduling maintenance cycles, calculated by dividing total operational time by the number of failures. MTTF serves as a key metric for products with fixed lifespans, such as electronic components or batteries, guiding product design and warranty periods.

Defining Mean Time to Failure (MTTF)

Mean Time to Failure (MTTF) defines the average operational time before a non-repairable system or component fails, providing key reliability metrics in product lifecycle analysis. It differs from Mean Time Between Failure (MTBF), which measures time between failures for repairable systems. Accurate MTTF assessments are essential for predicting product lifespan and planning maintenance in engineering and manufacturing industries.

Understanding Mean Time Between Failures (MTBF)

Mean Time Between Failures (MTBF) measures the average operational time between inherent failures of a system during normal usage, reflecting reliability and maintenance needs. Unlike Mean Time To Failure (MTTF), which applies to non-repairable systems and indicates expected lifespan until failure, MTBF is relevant for repairable systems, including machinery and electronic equipment. Accurate MTBF data assists in predictive maintenance scheduling, reducing downtime and optimizing resource allocation for improved system performance.

Key Differences between MTTF and MTBF

Mean Time to Failure (MTTF) measures the average operational time until a non-repairable product or component fails, indicating total lifespan. Mean Time Between Failures (MTBF) applies to repairable systems, calculating the average time between consecutive failures and includes repair time. Key differences include MTTF's use for non-repairable items and MTBF's focus on repairable systems, with MTBF factoring in downtime and maintenance intervals.

Importance of MTTF in Non-Repairable Systems

Mean Time to Failure (MTTF) is a critical metric for non-repairable systems as it quantifies the average operational lifespan before a device or component fails, enabling accurate reliability predictions and lifecycle planning. Unlike Mean Time Between Failures (MTBF), which applies to repairable systems by measuring the average time between breakdowns, MTTF provides essential data for designing maintenance schedules, warranty periods, and safety assessments for disposable products. Prioritizing MTTF helps manufacturers improve product durability, optimize resource allocation, and enhance customer satisfaction through reliable performance expectations.

Relevance of MTBF in Repairable Systems

Mean time between failure (MTBF) is a critical metric for repairable systems, measuring the average operational time between inherent failures, which directly impacts system reliability and maintenance planning. Unlike mean time to failure (MTTF), which applies to non-repairable systems and indicates the expected lifetime until failure, MTBF includes repair duration and assesses long-term system availability. MTBF data guides predictive maintenance and improves lifecycle management by optimizing repair intervals and minimizing downtime in complex repairable systems.

Calculation Methods for MTTF and MTBF

Mean Time to Failure (MTTF) is calculated by dividing the total operational time of non-repairable systems by the number of units tested until failure occurs, providing an average expected lifespan. Mean Time Between Failures (MTBF) involves summing the total operational time and dividing it by the number of failures during the observed period for repairable systems, reflecting the average time between consecutive failures. Both metrics rely on accurate failure data collection, with MTTF focusing on non-repairable items and MTBF emphasizing the maintainability and reliability of repairable equipment.

Factors Affecting MTTF and MTBF

Mean Time to Failure (MTTF) and Mean Time Between Failures (MTBF) are influenced by factors such as operating environment, maintenance practices, and component quality. Temperature extremes, vibration levels, and electrical stress can accelerate wear, reducing both MTTF and MTBF. Consistent preventive maintenance and high-quality materials contribute to extending the operational lifespan and reliability of equipment.

Practical Applications in Industry

Mean Time to Failure (MTTF) measures the average operational time before a non-repairable system fails, crucial for designing product warranties and predicting lifespans in electronics manufacturing. Mean Time Between Failures (MTBF) applies to repairable systems, providing valuable insights for scheduling maintenance and improving reliability in industries such as aerospace and automotive. Utilizing MTTF and MTBF metrics enhances operational efficiency by minimizing downtime and optimizing asset management strategies across industrial applications.

Choosing the Right Metric for Reliability Analysis

Mean Time to Failure (MTTF) measures the average operational time before a non-repairable system fails, while Mean Time Between Failures (MTBF) applies to repairable systems, representing the average time between consecutive failures. Selecting the right metric depends on the system's maintenance strategy and repairability; MTTF suits components that are replaced upon failure, whereas MTBF is ideal for systems with maintenance and repair cycles. Accurate reliability analysis requires understanding the nature of the system to effectively predict downtime and plan maintenance schedules.

Mean time to failure Infographic

libterm.com

libterm.com