A solid shaft provides a robust and reliable solution for transmitting torque in various mechanical systems due to its uniform cross-section and high strength. Its design optimizes durability and performance in applications ranging from automotive to industrial machinery. Discover how selecting the right solid shaft can enhance your equipment's efficiency by reading the rest of the article.

Table of Comparison

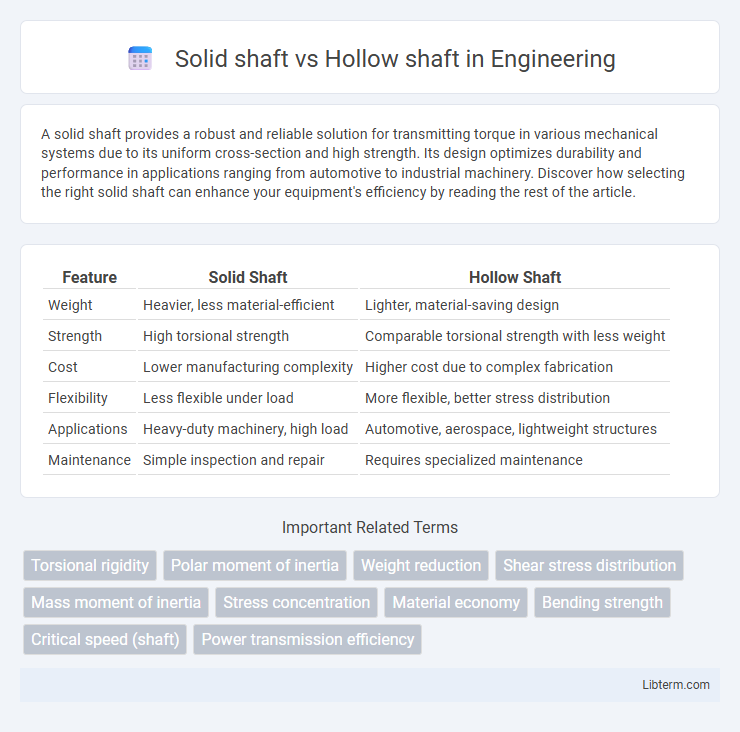

| Feature | Solid Shaft | Hollow Shaft |

|---|---|---|

| Weight | Heavier, less material-efficient | Lighter, material-saving design |

| Strength | High torsional strength | Comparable torsional strength with less weight |

| Cost | Lower manufacturing complexity | Higher cost due to complex fabrication |

| Flexibility | Less flexible under load | More flexible, better stress distribution |

| Applications | Heavy-duty machinery, high load | Automotive, aerospace, lightweight structures |

| Maintenance | Simple inspection and repair | Requires specialized maintenance |

Introduction to Solid vs Hollow Shafts

Solid shafts provide higher torsional strength and rigidity, making them ideal for heavy-duty mechanical applications where load resistance is critical. Hollow shafts offer a lighter weight alternative with improved strength-to-weight ratios, enhancing performance in applications requiring reduced inertia. Material efficiency and cost-effectiveness influence the choice between solid and hollow shafts in engineering design.

Material Efficiency and Weight Comparison

Hollow shafts offer superior material efficiency compared to solid shafts by reducing weight without compromising strength, making them ideal for applications requiring high torque-to-weight ratios. The weight reduction in hollow shafts can reach up to 30-50% relative to solid shafts of equivalent diameter, enhancing energy efficiency and performance in automotive and aerospace industries. Material savings from hollow shafts not only decrease raw material costs but also contribute to lower inertia, improving dynamic response and overall system durability.

Strength Characteristics of Solid and Hollow Shafts

Solid shafts exhibit higher torsional rigidity and can withstand greater bending moments due to their uniform cross-sectional area, making them suitable for applications requiring maximum strength and stiffness. Hollow shafts provide a more efficient strength-to-weight ratio by concentrating material away from the center, resulting in comparable torsional strength with reduced weight and improved resistance to bending under dynamic loads. Engineering design calculations often favor hollow shafts in structures and rotating machinery where minimizing mass without sacrificing performance is critical.

Torsional Rigidity and Torque Transmission

Hollow shafts offer higher torsional rigidity compared to solid shafts of the same weight, enhancing torque transmission efficiency in mechanical systems. The distribution of material away from the center axis in hollow shafts increases their polar moment of inertia, making them more resistant to twisting under load. For applications demanding lightweight components with strong torque handling, hollow shafts provide superior performance over solid shafts.

Cost Implications and Manufacturing Processes

Solid shafts generally incur higher material costs due to the increased volume of metal required, whereas hollow shafts optimize material usage, reducing overall expenses in applications where weight reduction is critical. Manufacturing processes for solid shafts often involve straightforward turning and machining, leading to lower production complexity and cost, while hollow shafts require more advanced techniques such as drilling or casting, increasing fabrication time and tooling investment. The cost implications of choosing between solid and hollow shafts hinge on balancing material savings against manufacturing challenges and the specific mechanical performance requirements of the application.

Applications in Engineering and Industry

Solid shafts are commonly used in heavy-duty applications requiring high torque transmission, such as in turbines, ship propeller shafts, and heavy machinery due to their strength and rigidity. Hollow shafts find extensive use in automotive and aerospace industries where weight reduction and torsional flexibility are critical, often applied in drive shafts and steering columns. The choice between solid and hollow shafts depends on factors like load requirements, weight constraints, and the need for vibration damping in engineering designs.

Durability and Fatigue Resistance

Solid shafts typically offer higher durability due to their uniform material distribution, which provides greater resistance to wear and mechanical stress. Hollow shafts excel in fatigue resistance by reducing weight and stress concentrations, allowing better absorption of cyclic loads without failure. Choosing between solid and hollow shafts depends on balancing the need for maximum strength with the advantages of lighter weight and improved fatigue life in dynamic applications.

Maintenance and Lifespan Considerations

Hollow shafts typically require less maintenance than solid shafts due to their reduced weight, which decreases bearing stress and wear over time. The hollow design enhances fatigue resistance, leading to a longer operational lifespan under cyclic loading conditions. However, solid shafts offer greater robustness and simpler repair procedures, making them more suitable for high-impact applications with less frequent maintenance intervals.

Choosing the Right Shaft for Your Project

When choosing the right shaft for your project, consider the application's torque requirements, weight constraints, and cost-effectiveness. Solid shafts offer superior strength and durability for heavy-duty tasks, while hollow shafts provide a lighter alternative that maintains adequate stiffness, improving efficiency in rotational applications. Evaluating factors such as load capacity, material properties, and installation environment ensures optimal performance and longevity.

Summary: Pros and Cons of Solid and Hollow Shafts

Solid shafts offer superior strength and durability, making them ideal for heavy-duty applications, but they tend to be heavier and less efficient in weight-sensitive designs. Hollow shafts provide reduced weight and improved torque-to-weight ratio, enhancing energy efficiency and rotational inertia, yet they may sacrifice some strength and rigidity compared to solid shafts. Selecting between solid and hollow shafts depends on balancing factors such as load capacity, weight constraints, and application-specific performance requirements.

Solid shaft Infographic

libterm.com

libterm.com