A compressor is a mechanical device that increases the pressure of a gas by reducing its volume, commonly used in HVAC systems, refrigeration, and industrial applications. Its efficiency directly impacts energy consumption and system performance. Discover how understanding compressor types and maintenance can optimize your equipment by reading the full article.

Table of Comparison

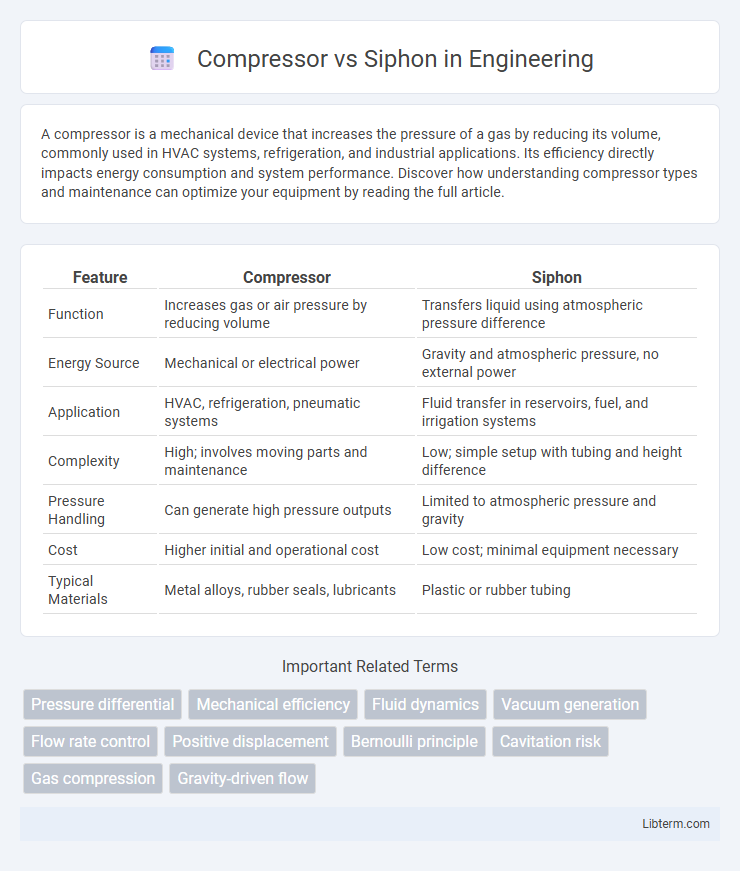

| Feature | Compressor | Siphon |

|---|---|---|

| Function | Increases gas or air pressure by reducing volume | Transfers liquid using atmospheric pressure difference |

| Energy Source | Mechanical or electrical power | Gravity and atmospheric pressure, no external power |

| Application | HVAC, refrigeration, pneumatic systems | Fluid transfer in reservoirs, fuel, and irrigation systems |

| Complexity | High; involves moving parts and maintenance | Low; simple setup with tubing and height difference |

| Pressure Handling | Can generate high pressure outputs | Limited to atmospheric pressure and gravity |

| Cost | Higher initial and operational cost | Low cost; minimal equipment necessary |

| Typical Materials | Metal alloys, rubber seals, lubricants | Plastic or rubber tubing |

Compressor vs Siphon: Key Differences

Compressor systems use mechanical energy to increase the pressure of gases, enabling efficient transport and storage, while siphon relies on gravity and atmospheric pressure to move liquids through a tube. Compressors are ideal for applications requiring high pressure and controlled flow, such as refrigeration and pneumatic tools, whereas siphons are typically used for simple liquid transfer without external power. Key differences include energy consumption, pressure control, and complexity, with compressors offering high precision and power use, and siphons providing passive, low-energy operation.

How Compressors Work

Compressors function by increasing the pressure of a gas by reducing its volume, typically using a mechanical device such as a piston or rotary impeller to force the gas into a smaller space. This process raises the gas density and temperature, enabling efficient transport, storage, or use in various applications like refrigeration, air conditioning, and gas pipelines. Unlike siphons, which rely on gravity and atmospheric pressure to move liquids, compressors actively amplify pressure, allowing them to handle gases and deliver controlled flow rates at higher pressures.

How Siphons Operate

Siphons operate by utilizing atmospheric pressure and gravity to move liquid from a higher elevation to a lower one through a tube, creating continuous flow without mechanical assistance. The liquid flows over the siphon's crest, where the pressure difference between the inlet and outlet drives the movement. Unlike compressors that add energy to gases mechanically, siphons rely purely on gravitational potential energy and pressure differentials to function.

Applications of Compressors

Compressors are widely used in HVAC systems to increase refrigerant pressure and facilitate heat transfer, playing a critical role in air conditioning and refrigeration. They are essential in industrial processes such as pneumatic tools operation, gas transportation, and chemical synthesis where pressurized air or gas is required. Compared to siphons, compressors enable active fluid movement and pressure modulation, making them indispensable in energy and manufacturing sectors.

Applications of Siphons

Siphons are widely used in applications such as aquariums, plumbing, and irrigation systems to transfer liquids efficiently without mechanical pumps. They rely on atmospheric pressure and gravity to move fluids from higher to lower elevations, making them ideal for draining tanks or emptying pools. Their simplicity and low cost make siphons a preferred choice for environmental engineering and fluid management in both residential and industrial settings.

Efficiency Comparison: Compressor vs Siphon

Compressors typically offer higher efficiency in controlled environments by precisely regulating pressure and flow rates, resulting in optimized energy consumption. Siphons rely on gravitational force and atmospheric pressure, which can limit their efficiency due to variable environmental factors and potential energy losses. When comparing compressor vs siphon systems, compressors generally outperform siphons in energy efficiency, especially in industrial applications requiring consistent and adjustable flow control.

Energy Consumption Analysis

Compressor systems generally consume more energy than siphon systems due to their reliance on mechanical components to increase refrigerant pressure. In contrast, siphon systems utilize gravitational and pressure differentials to facilitate fluid movement, resulting in lower energy requirements. Energy consumption analysis reveals that siphon systems offer a more energy-efficient alternative, especially in applications where reducing operational costs is critical.

Pros and Cons: Compressor Systems

Compressor systems provide efficient air compression with high pressure output and consistent performance, making them ideal for industrial applications requiring reliable airflow. However, they tend to consume more energy, generate noise, and require regular maintenance to prevent overheating and mechanical failure. Despite higher operational costs, compressors offer precise control and durability compared to siphon systems, which may have limitations in pressure regulation and energy efficiency.

Pros and Cons: Siphon Systems

Siphon systems offer the advantage of lower energy consumption compared to compressors, making them more cost-effective and environmentally friendly for certain applications. However, they rely heavily on gravity and pressure differentials, which can limit their efficiency and performance in situations requiring significant pressure boosts or where elevation changes are minimal. Maintenance is generally simpler for siphon systems but they may struggle with inconsistent flow rates and are less versatile than compressor-based solutions.

Choosing the Right Solution: Compressor or Siphon

Choosing between a compressor and a siphon hinges on the specific application and desired efficiency; compressors are ideal for pressurized air delivery systems requiring consistent flow and higher pressures, whereas siphons leverage gravity for fluid transfer without energy consumption. Consider factors such as energy availability, system complexity, and maintenance needs to determine the optimal solution. For industrial usage demanding controlled pressure and volume, compressors offer superior performance, while siphons provide an eco-friendly, low-cost option for simple liquid movement tasks.

Compressor Infographic

libterm.com

libterm.com