Grinding is a crucial process in manufacturing that shapes materials to precise dimensions and finishes by removing excess surface material. This method enhances the durability and performance of components used in industries such as automotive, aerospace, and electronics. Discover how grinding can improve Your production quality and meet stringent industry standards by exploring the rest of the article.

Table of Comparison

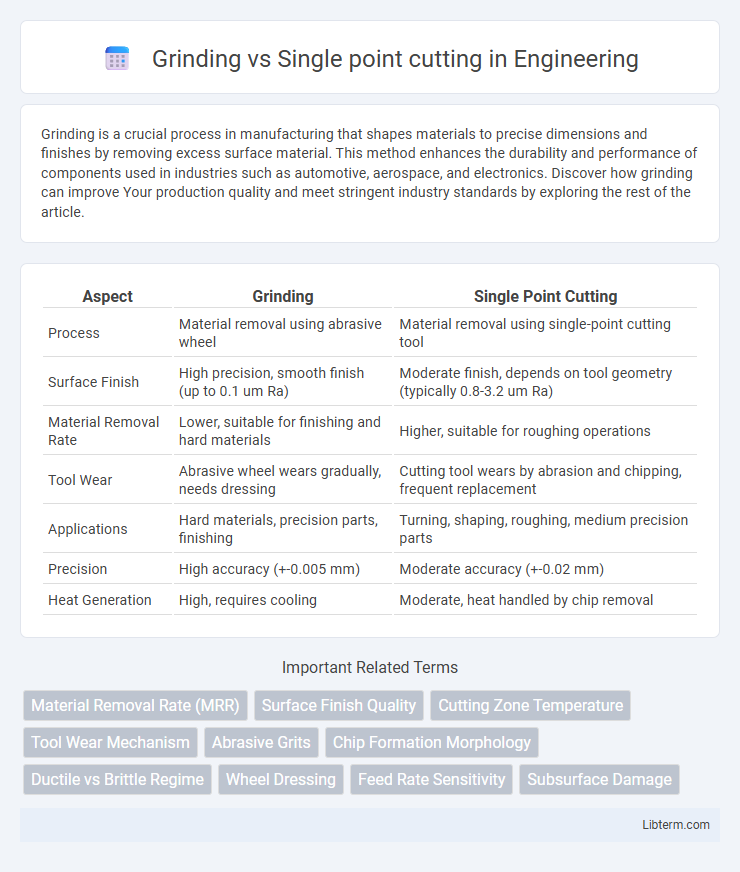

| Aspect | Grinding | Single Point Cutting |

|---|---|---|

| Process | Material removal using abrasive wheel | Material removal using single-point cutting tool |

| Surface Finish | High precision, smooth finish (up to 0.1 um Ra) | Moderate finish, depends on tool geometry (typically 0.8-3.2 um Ra) |

| Material Removal Rate | Lower, suitable for finishing and hard materials | Higher, suitable for roughing operations |

| Tool Wear | Abrasive wheel wears gradually, needs dressing | Cutting tool wears by abrasion and chipping, frequent replacement |

| Applications | Hard materials, precision parts, finishing | Turning, shaping, roughing, medium precision parts |

| Precision | High accuracy (+-0.005 mm) | Moderate accuracy (+-0.02 mm) |

| Heat Generation | High, requires cooling | Moderate, heat handled by chip removal |

Introduction to Material Removal Processes

Grinding and single point cutting are fundamental material removal processes used to shape and finish components with precision. Grinding employs an abrasive wheel to remove fine amounts of material, achieving high surface quality and tight tolerances, while single point cutting utilizes a single cutting edge to remove material through shear deformation, typically used in turning and shaping operations. Both methods are essential for achieving desired dimensions, surface texture, and mechanical properties in manufacturing.

Overview of Grinding Techniques

Grinding techniques involve the use of abrasive wheels or belts to remove material through micro-cutting actions, providing high precision and superior surface finish compared to single point cutting. Common grinding methods include surface grinding, cylindrical grinding, and centerless grinding, each tailored for specific geometric and tolerance requirements in parts production. These techniques excel in machining hard materials and achieving tight dimensional accuracy, making them essential in industries like aerospace and automotive manufacturing.

Fundamentals of Single Point Cutting

Single point cutting involves the removal of material from a workpiece using a single cutting edge, typically found in tools such as lathe tools and shapers. The fundamental principles include chip formation, tool geometry, cutting forces, and heat generation, which directly impact surface finish and tool life. Understanding the mechanics of single point cutting is crucial for optimizing machining parameters and achieving precision in turning and shaping operations compared to grinding processes.

Comparison of Cutting Mechanisms

Grinding utilizes abrasive particles embedded in a wheel to remove material through micro-cutting and plowing actions, producing fine surface finishes with minimal thermal damage. Single point cutting employs a single sharp tool edge to shear material in a chip formation process, enabling precise dimensional control and efficient metal removal on simple geometries. The key difference lies in grinding's multi-cutting micro-asperities versus single point cutting's continuous chip flow, influencing surface integrity and process efficiency.

Surface Finish and Tolerances

Grinding provides superior surface finish and tighter dimensional tolerances compared to single-point cutting due to its abrasive cutting action and high spindle speeds. Surface roughness values in grinding can reach as low as 0.1 micrometers Ra, while single-point cutting typically results in higher roughness around 1-2 micrometers Ra. Tolerances in grinding can be maintained within +-0.001 mm, making it ideal for precision components where accuracy and surface integrity are critical.

Tool Materials and Wear Characteristics

Grinding utilizes abrasive wheels composed of hard materials like aluminum oxide or silicon carbide, offering superior wear resistance and precision for hard alloys. Single point cutting tools are typically made from high-speed steel, carbide, or ceramic materials, which provide sharp edges but exhibit more rapid wear under high-temperature or high-stress conditions. The abrasive nature of grinding results in gradual tool wear with better heat dissipation, whereas single point cutting often suffers from localized tool wear such as flank and crater wear, impacting tool life and surface finish quality.

Applications in Manufacturing

Grinding is widely used in manufacturing for finishing operations that require high precision and surface quality, such as in tool and die making, aerospace components, and automotive parts, where tight tolerances and fine surface finishes are critical. Single point cutting is primarily applied in turning, shaping, and boring processes to remove material efficiently in rough and semi-finish machining of shafts, gears, and engine components, delivering high productivity with moderate surface finish requirements. Both methods complement each other, with single point cutting often preceding grinding to shape parts before achieving final dimensions and surface characteristics.

Process Efficiency and Productivity

Grinding offers higher surface finish quality and precision compared to single point cutting, making it ideal for finishing operations in high-precision industries. Single point cutting enables faster material removal and is more efficient for roughing due to its ability to handle larger chip loads and lower tooling costs. Process productivity improves when combining single point cutting for bulk removal and grinding for fine detailing, optimizing cycle times and cost-effectiveness.

Cost Considerations

Grinding generally incurs higher initial equipment costs and maintenance expenses compared to single point cutting due to the complexity of grinding machines and abrasive wheels. Single point cutting often offers lower operational costs and faster setup times, making it more economical for simpler or lower-volume production runs. Cost efficiency in grinding improves with high-volume, precision applications where the superior surface finish and tight tolerances justify the investment.

Choosing the Right Process for Your Needs

Grinding offers superior surface finish and tighter tolerances, making it ideal for hard materials and finishing operations, while single point cutting excels in shaping and roughing tasks with greater material removal rates. Selecting the right process depends on factors like the required precision, material hardness, production volume, and cost considerations. For applications demanding intricate details and minimal surface roughness, grinding is preferred; for faster, more versatile cuts, single point cutting is often more efficient.

Grinding Infographic

libterm.com

libterm.com