Projection welding is a precise resistance welding technique where raised sections, or projections, concentrate the welding current and pressure to specific areas, creating strong and consistent welds. This process is ideal for joining small or intricate metal parts with minimal distortion and enhances production efficiency in automotive, aerospace, and electronics industries. Explore the rest of the article to discover how projection welding can improve your manufacturing outcomes.

Table of Comparison

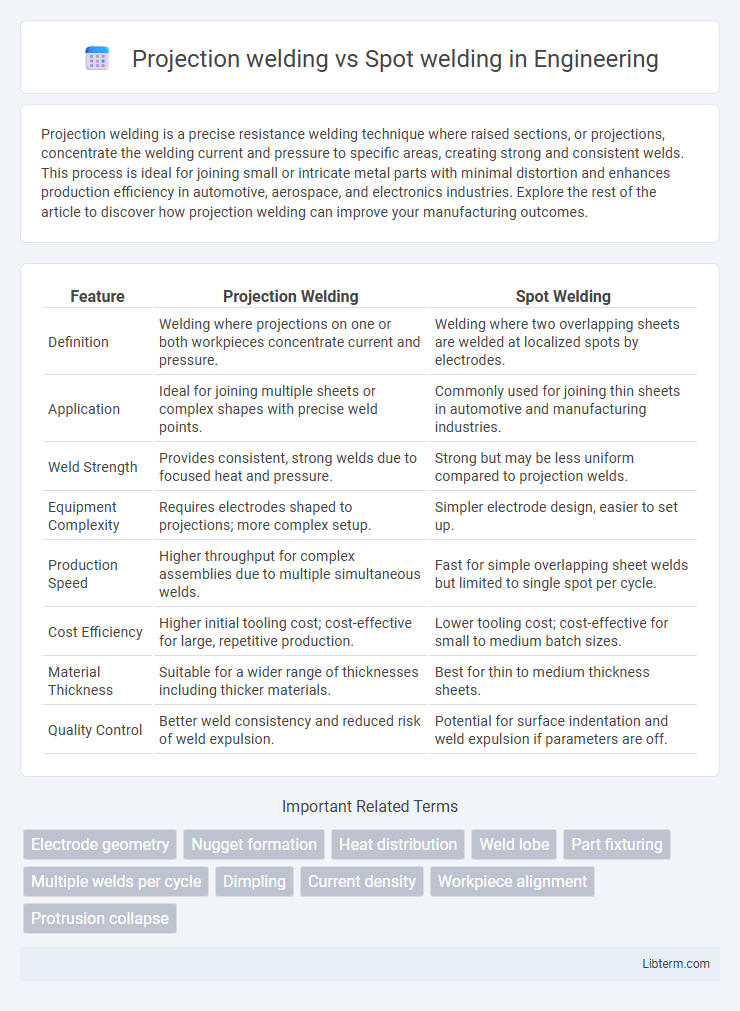

| Feature | Projection Welding | Spot Welding |

|---|---|---|

| Definition | Welding where projections on one or both workpieces concentrate current and pressure. | Welding where two overlapping sheets are welded at localized spots by electrodes. |

| Application | Ideal for joining multiple sheets or complex shapes with precise weld points. | Commonly used for joining thin sheets in automotive and manufacturing industries. |

| Weld Strength | Provides consistent, strong welds due to focused heat and pressure. | Strong but may be less uniform compared to projection welds. |

| Equipment Complexity | Requires electrodes shaped to projections; more complex setup. | Simpler electrode design, easier to set up. |

| Production Speed | Higher throughput for complex assemblies due to multiple simultaneous welds. | Fast for simple overlapping sheet welds but limited to single spot per cycle. |

| Cost Efficiency | Higher initial tooling cost; cost-effective for large, repetitive production. | Lower tooling cost; cost-effective for small to medium batch sizes. |

| Material Thickness | Suitable for a wider range of thicknesses including thicker materials. | Best for thin to medium thickness sheets. |

| Quality Control | Better weld consistency and reduced risk of weld expulsion. | Potential for surface indentation and weld expulsion if parameters are off. |

Introduction to Projection and Spot Welding

Projection welding uses raised sections or projections on one or both workpieces to concentrate the welding current and pressure, resulting in strong, localized welds ideal for complex shapes and varying thicknesses. Spot welding involves clamping two overlapping metal sheets and applying electric current through electrodes at small spots, creating welds primarily used in thin sheet metal fabrication and automotive assembly. Both techniques rely on resistance welding principles but differ significantly in electrode design and heat concentration, affecting their applications and efficiency in manufacturing.

Fundamentals of Projection Welding

Projection welding concentrates current and force on small raised sections or projections on one or both workpieces, ensuring consistent and localized heat generation for strong welds. Unlike spot welding, which applies pressure and current directly between two flat surfaces, projection welding uses these projections to improve weld quality by controlling weld nugget size and reducing electrode wear. This targeted approach in projection welding enhances joint strength, repeatability, and efficiency in thicker or more complex materials.

Fundamentals of Spot Welding

Spot welding relies on the principle of resistance heating, where two overlapping metal sheets are joined by applying pressure and passing a high electric current through the contact point. The heat generated at the interface causes localized melting and solidification, forming a strong weld nugget without the need for filler material. Projection welding differs by concentrating current and pressure on raised projections, enabling efficient joining of components with complex geometries or multiple spots.

Key Differences Between Projection and Spot Welding

Projection welding concentrates current and pressure on small raised projections, allowing deeper welds and better alignment of components, while spot welding applies current and pressure directly through overlapping sheets. Projection welding typically offers stronger welds with reduced distortion and is effective for joining complex shapes, whereas spot welding is faster and more suited for thin sheet materials. Key differences include weld strength, precision, electrode wear, and suitability for varying part geometries.

Advantages of Projection Welding

Projection welding offers superior strength and consistency compared to spot welding due to its precise control over electrode placement and pressure distribution, which enhances weld quality. This method reduces electrode wear and maintenance costs by concentrating current on defined projections, resulting in lower energy consumption and improved material utilization. Projection welding also allows for welding of complex assemblies with multiple simultaneous welds, increasing production efficiency and throughput.

Advantages of Spot Welding

Spot welding offers superior speed and efficiency by creating welds at multiple points simultaneously, which reduces production time and labor costs in high-volume manufacturing. It provides excellent strength and durability for thin materials, making it ideal for automotive and electronic assemblies requiring precise, consistent welds. The process also minimizes distortion and preserves material integrity compared to projection welding, enhancing overall product quality.

Typical Applications of Projection Welding

Projection welding is commonly used in manufacturing applications requiring precise, high-strength welds on complex or irregularly shaped components, such as automotive parts, electrical connectors, and fasteners. This method excels in joining multi-layered materials and metal sheets with localized projections, enabling efficient heat generation and consistent weld quality. Typical uses include welding nuts to plates, attaching louvered electrical contacts, and assembling battery tabs, where controlled weld size and placement are critical.

Typical Applications of Spot Welding

Spot welding is widely used in automotive manufacturing for joining sheet metal components due to its speed and efficiency in creating strong, localized welds. It is commonly applied in appliance production, such as refrigerators and washing machines, where consistent weld quality on thin metal sheets is crucial. Electronics and aerospace industries also employ spot welding for assembling delicate metal parts with precision and minimal thermal distortion.

Factors to Consider When Choosing Weld Type

Choosing between projection welding and spot welding depends primarily on material thickness, part design, and production volume. Projection welding offers better control for joining irregular or thicker materials due to its localized heating at raised sections, while spot welding suits thinner, flat materials and provides faster cycle times. Consider factors like electrical current distribution, electrode force, and cost efficiency to optimize weld quality and operational efficiency.

Conclusion: Choosing the Right Welding Method

Selecting the appropriate welding method depends on the specific application, material thickness, and joint design. Projection welding excels in providing strong, precise welds for complex assemblies with raised projections, offering better control over heat and pressure. Spot welding is ideal for quick, efficient joining of thin sheets with overlapping surfaces, making it a cost-effective choice for high-volume production.

Projection welding Infographic

libterm.com

libterm.com