Brushed DC motors are widely used in various applications due to their simple design and reliable performance. These motors operate by passing current through brushes that make contact with the commutator, generating a magnetic field to produce rotational motion. Explore the rest of the article to understand how a brushed DC motor can enhance your project's efficiency and control.

Table of Comparison

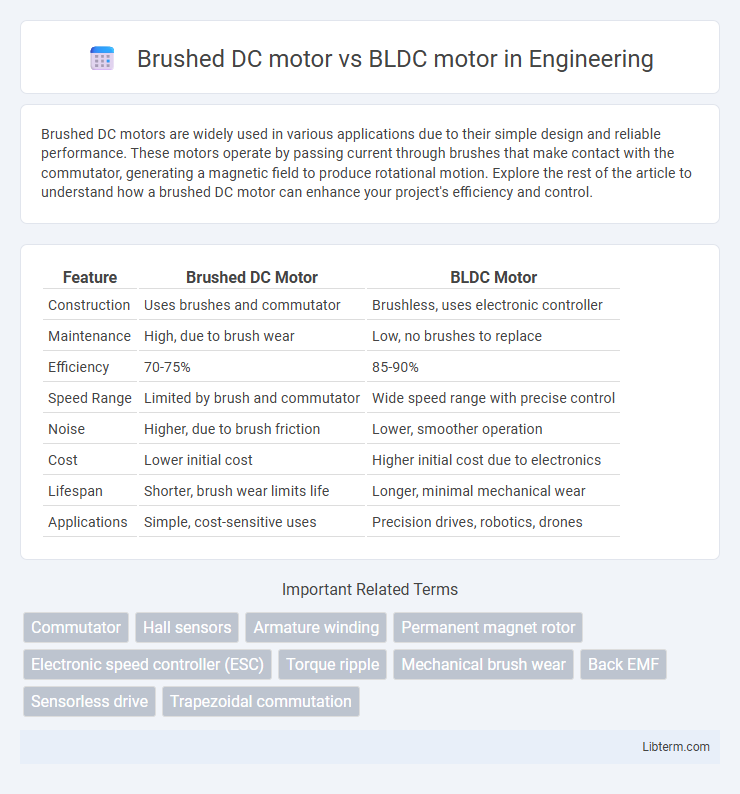

| Feature | Brushed DC Motor | BLDC Motor |

|---|---|---|

| Construction | Uses brushes and commutator | Brushless, uses electronic controller |

| Maintenance | High, due to brush wear | Low, no brushes to replace |

| Efficiency | 70-75% | 85-90% |

| Speed Range | Limited by brush and commutator | Wide speed range with precise control |

| Noise | Higher, due to brush friction | Lower, smoother operation |

| Cost | Lower initial cost | Higher initial cost due to electronics |

| Lifespan | Shorter, brush wear limits life | Longer, minimal mechanical wear |

| Applications | Simple, cost-sensitive uses | Precision drives, robotics, drones |

Introduction to Brushed DC Motors and BLDC Motors

Brushed DC motors use carbon brushes and a commutator to deliver current to the rotor windings, enabling torque generation through electromagnetic interaction. BLDC (Brushless DC) motors eliminate brushes by employing electronic commutation with permanent magnets on the rotor and stator windings controlled by an external controller, resulting in higher efficiency and reliability. Both types serve diverse applications, but BLDC motors are preferred in environments demanding reduced maintenance and enhanced performance.

Basic Working Principles

Brushed DC motors operate using a mechanical commutator and brushes to switch current direction within the rotor windings, creating a magnetic field that interacts with the stator magnets to produce rotation. In contrast, BLDC (Brushless DC) motors utilize electronic commutation through a controller to energize the stator coils in sequence, eliminating the need for brushes and commutators. This difference in commutation method results in higher efficiency, reduced maintenance, and improved reliability in BLDC motors compared to traditional brushed DC motors.

Key Components and Construction

Brushed DC motors feature a rotor with windings connected to a commutator and brushes that transfer current, enabling mechanical switching. BLDC motors replace brushes and commutators with electronic controllers, using permanent magnets on the rotor and a stator with multiple windings for efficient torque generation. The absence of brushes in BLDC motors reduces friction and wear, leading to higher durability and quieter operation.

Performance and Efficiency Comparison

Brushed DC motors generally exhibit lower efficiency, around 75-80%, due to friction and electrical losses from brushes and commutators, resulting in reduced performance and shorter lifespan compared to BLDC motors. Brushless DC (BLDC) motors achieve higher efficiency, often exceeding 85-90%, because their electronic commutation eliminates brush friction, allowing for better speed control, higher torque-to-weight ratio, and longer operational life. In industrial and high-performance applications, BLDC motors deliver superior energy efficiency and consistent performance, making them preferable over brushed DC motors despite higher initial costs.

Control and Commutation Methods

Brushed DC motors use mechanical brushes and a commutator for direct current commutation, enabling straightforward but wear-prone control and limited speed regulation. BLDC motors utilize electronic commutation via Hall effect sensors or sensorless methods, providing precise, efficient control with reduced maintenance and improved dynamic response. The brushless design enables advanced speed, torque control, and integration with digital controllers for optimized motor performance.

Maintenance and Longevity

Brushed DC motors require frequent maintenance due to brush and commutator wear, which limits their lifespan and increases downtime. BLDC motors feature electronic commutation, eliminating brushes and significantly reducing maintenance needs while enhancing durability. The absence of mechanical brushes in BLDC motors results in longer operational life and higher reliability in demanding applications.

Cost and Availability

Brushed DC motors generally have lower upfront costs due to simpler design and widespread manufacturing, making them more affordable and readily available for basic applications. BLDC motors, while more expensive initially because of complex electronics and high-precision components, are increasingly accessible as production scales and demand in industries like automotive and robotics rises. Cost efficiency of BLDC motors improves over time through lower maintenance and higher energy efficiency, balancing initial investment with long-term savings.

Applications in Industry

Brushed DC motors are commonly used in applications requiring simple speed control and low initial cost, such as in small machinery, automotive components, and household appliances. BLDC motors dominate industries like robotics, aerospace, and electric vehicles due to their high efficiency, longer lifespan, and reduced maintenance needs. Industries increasingly prefer BLDC motors for precise control and energy savings in automation systems and HVAC equipment.

Advantages and Disadvantages

Brushed DC motors offer simplicity, low initial cost, and easy speed control but suffer from higher maintenance due to brush and commutator wear, resulting in shorter lifespan and lower efficiency. BLDC motors provide higher efficiency, longer lifespan, reduced noise, and better speed-torque characteristics with minimal maintenance since they use electronic commutation instead of brushes. However, BLDC motors require more complex control electronics and typically have a higher upfront cost compared to brushed DC motors.

Which Motor is Right for Your Application?

Brushed DC motors offer simple design and lower initial cost, making them ideal for applications requiring low to moderate power and easy control, such as household appliances and toys. BLDC motors provide higher efficiency, longer lifespan, and better performance at high speeds, suitable for electric vehicles, drones, and industrial automation. Choosing the right motor depends on factors like cost constraints, maintenance needs, power requirements, and expected operational environment.

Brushed DC motor Infographic

libterm.com

libterm.com