Screw pumps utilize interlocking helical screws to move fluids efficiently through a sealed casing, ensuring smooth and continuous flow with minimal pulsation. They are ideal for handling viscous liquids, slurries, and those containing solids, offering reliable performance in various industrial applications. Discover how screw pumps can optimize your fluid handling processes by exploring the full article.

Table of Comparison

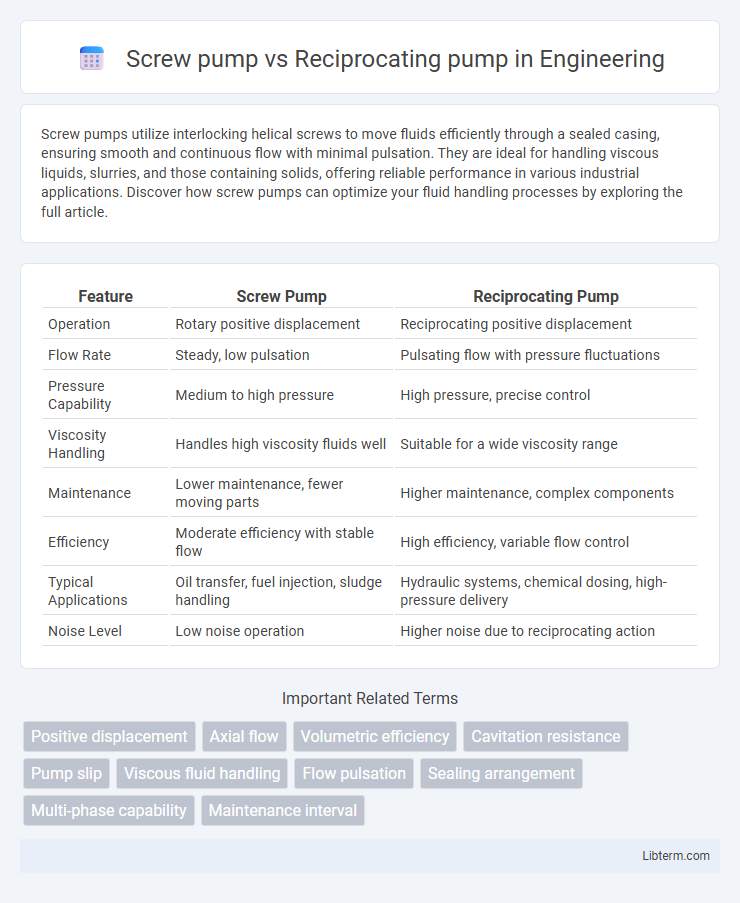

| Feature | Screw Pump | Reciprocating Pump |

|---|---|---|

| Operation | Rotary positive displacement | Reciprocating positive displacement |

| Flow Rate | Steady, low pulsation | Pulsating flow with pressure fluctuations |

| Pressure Capability | Medium to high pressure | High pressure, precise control |

| Viscosity Handling | Handles high viscosity fluids well | Suitable for a wide viscosity range |

| Maintenance | Lower maintenance, fewer moving parts | Higher maintenance, complex components |

| Efficiency | Moderate efficiency with stable flow | High efficiency, variable flow control |

| Typical Applications | Oil transfer, fuel injection, sludge handling | Hydraulic systems, chemical dosing, high-pressure delivery |

| Noise Level | Low noise operation | Higher noise due to reciprocating action |

Introduction to Screw Pumps and Reciprocating Pumps

Screw pumps utilize one or more screws rotating inside a cylinder to move fluids smoothly and continuously, making them ideal for handling viscous liquids and maintaining steady flow rates. Reciprocating pumps operate through the back-and-forth motion of a piston or plunger within a cylinder, delivering precise volume control and high pressure, suitable for applications requiring accurate dosing and high discharge pressures. Both pump types serve distinct industrial roles, with screw pumps excelling in low-pulsation fluid transfer and reciprocating pumps favored for high-pressure and metered flow tasks.

Basic Working Principles

Screw pumps operate using one or more screws rotating inside a cylinder to move fluid axially through the pump, creating a steady, continuous flow with low pulsation. Reciprocating pumps function by a piston or plunger moving back and forth within a cylinder, generating pressure changes that draw fluid in during the suction stroke and force it out during the discharge stroke. The screw pump's rotary motion contrasts with the reciprocating pump's linear motion, affecting flow characteristics and application suitability.

Key Components and Design Features

Screw pumps feature helical screws that rotate within a cylindrical casing to transfer fluid smoothly, characterized by minimal pulsation and a continuous flow design. Reciprocating pumps utilize a piston or plunger moving back and forth inside a cylinder, incorporating valves to control fluid intake and discharge, resulting in pulsating flow with high pressure capabilities. The key components of screw pumps include screws, casing, bearings, and seals, whereas reciprocating pumps rely on cylinders, pistons, valves, and crossheads to manage fluid movement and pressure.

Performance and Efficiency Comparison

Screw pumps deliver smooth, continuous flow with low pulsation and high volumetric efficiency, ideal for handling viscous fluids with minimal shear. Reciprocating pumps provide high pressure and precise flow control but experience pulsating discharge and higher mechanical wear, leading to lower overall efficiency in continuous operation. Performance-wise, screw pumps excel in energy efficiency and maintenance costs for steady flow applications, while reciprocating pumps perform better in high-pressure, low-flow scenarios.

Application Areas and Industry Usage

Screw pumps excel in handling viscous fluids, sludges, and shear-sensitive materials, making them ideal for wastewater treatment, oil and gas, and food processing industries. Reciprocating pumps provide high pressure and precise flow control, suited for chemical dosing, hydraulic systems, and high-pressure oil transfer applications. Both pump types serve diverse sectors, but screw pumps dominate in continuous, low-pulsation flow scenarios while reciprocating pumps are preferred for intermittent, high-pressure tasks.

Flow Rate and Pressure Capabilities

Screw pumps deliver smooth, continuous flow with high flow rates up to 1,000 m3/h, maintaining moderate pressure levels typically around 10-20 bar. Reciprocating pumps excel in generating high pressures exceeding 200 bar but generally operate at lower flow rates, often below 200 m3/h. The choice between screw and reciprocating pumps depends on the application's demand for either steady volumetric flow or high-pressure output.

Maintenance Requirements and Reliability

Screw pumps offer low maintenance requirements due to fewer moving parts and continuous, smooth operation that reduces wear and tear compared to reciprocating pumps. Reciprocating pumps require more frequent maintenance because of their numerous seals, valves, and pistons that experience higher mechanical stress and potential leakage. Screw pumps deliver higher reliability in demanding applications by minimizing downtime and often requiring less specialized service expertise.

Cost and Energy Consumption

Screw pumps generally offer lower maintenance costs and more efficient energy consumption due to their continuous flow design, which reduces pulsation and mechanical stress. Reciprocating pumps typically incur higher operational costs because of complex moving parts and intermittent flow, leading to increased wear and energy use. For applications demanding consistent flow and energy efficiency, screw pumps present a cost-effective solution compared to reciprocating pumps.

Advantages and Limitations

Screw pumps offer continuous, smooth flow with low pulsation and handle viscous fluids efficiently, making them ideal for applications requiring steady output and gentle fluid transfer. Reciprocating pumps provide high pressure and precise volume control, suitable for high-pressure applications and accurate dosing but may cause pulsation and require more maintenance due to moving parts. Screw pumps generally have lower maintenance costs and quieter operation, while reciprocating pumps excel in high-pressure environments but can be less efficient with viscous fluids and have higher wear rates.

Selecting the Right Pump for Your Needs

Screw pumps excel in handling viscous fluids with smooth, continuous flow and minimal pulsation, making them ideal for applications such as oil transfer and wastewater treatment. Reciprocating pumps provide high pressure and precise flow control, suited for processes requiring accurate dosing and high-pressure delivery, like chemical injection or hydraulic systems. Selecting the right pump depends on factors like fluid viscosity, required flow rate, pressure needs, and the importance of flow consistency in your specific application.

Screw pump Infographic

libterm.com

libterm.com